Comprehensive Guide to Textile Company Safety Emergency Response Plans

: Comprehensive Guide to Textile Company Safety Emergency Response Plans,In the textile industry, safety emergencies can have severe consequences if not properly addressed. This comprehensive guide provides essential information on how to develop and implement effective emergency response plans for textile companies. The plan should include clear protocols for identifying hazards, assessing risks, and responding to emergencies in a timely and efficient manner. It is also important to have a well-trained workforce who are familiar with the plan and its procedures. Additionally, regular drills and simulations should be conducted to ensure that everyone involved is prepared for an emergency. Finally, it is crucial to have a communication system in place to quickly notify employees, suppliers, and customers of any unforeseen events. By following these steps, textile companies can minimize the impact of safety emergencies and ensure the safety and well-being of their employees and stakeholders.

In today's competitive and ever-evolving global textile industry, the importance of safety cannot be overstated. A comprehensive safety emergency response plan is not just a necessity but a fundamental aspect of maintaining productivity, employee well-being, and corporate reputation. This guide aims to provide you with an in-depth understanding of how to develop and implement a robust safety emergency response plan for your textile company.

Table of Contents

- Introduction

- Understanding Safety Hazards

- Establishing a Safety Committee

- Developing a Detailed Safety Plan

- Training and Rehearsal

- Implementation and Follow-Up

- Monitoring and Reporting

- Case Study: A Successful Textile Company Safety Emergency Response

- Conclusion

Introduction

The textile industry is characterized by its high-energy, high-speed production processes and potential hazards such as fires, explosions, chemical spills, and worker injuries. A well-thought-out safety emergency response plan can significantly reduce these risks, ensuring the safety of employees and the integrity of the business operations. In this guide, we will delve into the key elements that make up a comprehensive safety emergency response plan for textile companies.

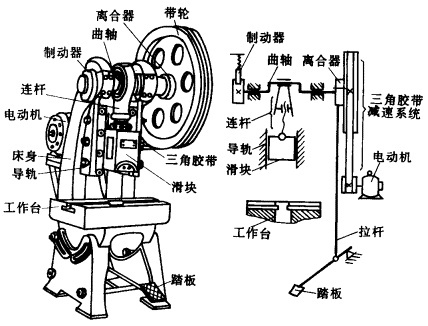

Understanding Safety Hazards

Before developing a safety plan, it is essential to identify and understand the various potential hazards within your textile company. These hazards could range from machinery failures, electrocutions, toxic substance exposures, to natural disasters like floods or earthquakes. By identifying these hazards, you can prioritize your efforts and tailor your safety plan accordingly.

Establishing a Safety Committee

A dedicated safety committee is the backbone of any effective safety emergency response plan. The committee should consist of representatives from different departments within the company, including management, engineering, quality control, human resources, and security. Their role is to oversee the implementation of the safety plan, ensure regular updates, and address any issues promptly.

Developing a Detailed Safety Plan

The safety plan should be comprehensive, covering all aspects of workplace safety, including emergency procedures, first aid, evacuation routes, and communication protocols. It should also include specific guidelines for handling hazardous materials and equipment. To ensure compliance with regulations, the plan should be reviewed and updated regularly to reflect changes in industry standards and best practices.

Training and Rehearsal

Effective training and rehearsals are critical components of any safety plan. All employees must be trained on the correct use of personal protective equipment (PPE), emergency procedures, and first aid techniques. Regular drills and simulations of emergency situations can help employees become familiar with their roles during an emergency and improve their ability to respond effectively.

Implementation and Follow-Up

Once the safety plan is developed and approved, it must be implemented across the company. This involves communicating the plan to all employees, ensuring that everyone understands their responsibilities during an emergency, and providing necessary resources and support. Regular follow-ups and reviews should be conducted to assess the effectiveness of the plan and make necessary adjustments.

Monitoring and Reporting

Continuous monitoring and reporting of incidents and accidents are essential for maintaining a safe work environment. Regular audits and inspections should be conducted to identify potential hazards and address them before they escalate. Incident reports should be documented accurately and promptly, allowing for lessons learned to be shared with other departments and stakeholders.

Case Study: A Successful Textile Company Safety Emergency Response

One example of a successful textile company safety emergency response is the case of a major fire outbreak at a leading textile manufacturer in China. The company had a comprehensive safety plan in place, which included regular training for employees, proper use of PPE, and clear evacuation procedures. When the fire broke out, the employees acted quickly and efficiently, following the established emergency procedures. The company was able to contain the fire and minimize the damage, thanks in part to its well-developed safety plan.

Conclusion

In conclusion, developing a comprehensive safety emergency response plan is crucial for ensuring the safety and well-being of employees in the textile industry. By understanding potential hazards, establishing a dedicated safety committee, developing a detailed safety plan, conducting regular training and rehearsals, implementing the plan, monitoring and reporting incidents, and learning from past experiences, you can create a strong foundation for a secure workplace. Remember, safety is not just a cost; it is a value that will protect your investment in employees and customers alike.

背景与目的

随着纺织品行业的快速发展,公司面临的安全风险日益增多,为了确保员工和客户的安全,制定一套完善的纺织品公司安全应急预案显得尤为重要,本预案旨在提高应对突发事件的能力,确保公司在突发事件发生时能够迅速、有效地进行应急处理,最大程度地减少损失。

应急预案内容

人员安全

(1)员工培训 定期为员工提供安全培训,包括但不限于火灾、地震、化学品泄漏等常见安全事件的应对措施,培训内容包括安全操作规程、应急处置流程、安全设备使用方法等。

(2)紧急疏散演练 定期组织紧急疏散演练,确保员工在紧急情况下能够迅速撤离,演练内容包括疏散路线、撤离时间、撤离过程中的注意事项等。

(3)应急物资储备 建立应急物资储备库,包括消防器材、急救用品、防护用品等,确保在突发事件发生时能够及时提供必要的应急物资。

设施安全

(1)设备检查与维护 定期对公司的生产设备进行全面检查和维护,确保设备正常运行,对于易损件要及时更换,防止因设备故障导致安全事故。

(2)消防设施检查 定期检查公司的消防设施是否完好有效,确保在火灾发生时能够及时启动灭火救援。

化学品安全

(1)化学品管理 建立化学品管理制度,明确化学品采购、存储、使用等各个环节的安全要求,确保化学品在使用过程中符合安全标准。

(2)应急处理措施 针对可能出现的化学品泄漏等突发事件,制定相应的应急处理措施,包括撤离受影响区域、封锁现场、联系救援等。

突发事件应对流程

(1)突发事件报告与初步处置 当发现突发事件时,立即向上级部门报告,同时启动初步处置流程,包括现场初步勘察、制定应急处置方案等。

(2)应急处置方案实施 根据初步处置方案,迅速开展应急处置工作,包括疏散受影响区域人员、联系救援队伍、调配应急物资等,加强与相关部门的沟通协调,形成合力应对突发事件。

案例分析 为了更好地执行本预案,我们以实际案例进行分析: 案例一:某纺织品公司发生化学品泄漏事故,立即启动应急预案,迅速疏散受影响区域人员,联系救援队伍,调配应急物资,最终成功控制了事故发展并恢复了生产秩序。 案例二:某地区发生地震灾害,纺织品公司迅速启动应急预案,组织疏散演练,确保员工和客户的安全,加强与当地政府部门的沟通协调,共同应对突发事件。

英文表格补充说明

以下是英文版的表格补充说明:

| 项目 | 中文说明 | 英文说明 |

|---|---|---|

| 人员安全 | 定期培训 | Regular safety training for employees |

| 紧急疏散演练 | 定期组织 | Regular emergency evacuation exercises |

| 应急物资储备 | 储备库建立 | Establish emergency supply reserves |

| 设施安全 | 设备检查与维护 | Regular equipment inspection and maintenance |

| 消防设施检查 | 检查频率 | Frequency of fire protection facilities inspection |

| 化学品安全 | 管理制度建立 | Establish chemical management system |

| 突发事件应对流程 | 报告与初步处置 | Report and initiate initial response procedures |

| 案例分析 | 化学品泄漏事故案例 | Chemical leak accident case study |

本预案旨在提高纺织品公司应对突发事件的能力,确保公司在突发事件发生时能够迅速、有效地进行应急处理,通过加强人员培训、紧急疏散演练、建立应急物资储备库、加强设施安全检查和配备消防设施等措施,可以有效降低安全事故的发生概率,保障员工和客户的安全,通过案例分析,可以更好地执行本预案,提高应对突发事件的能力。

Articles related to the knowledge points of this article:

Exploring the Wonders of Babys First Clothes

The Growth of Industrial Textiles in the Small Wood Market

The Essential Guide to Sports T-shirt Standards:A Comprehensive Analysis