Understanding the Causes of Fiber Breakage in Textiles

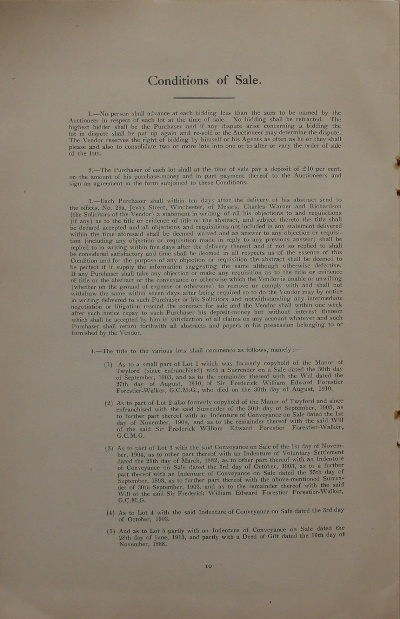

: Understanding the Causes of Fiber Breakage in Textiles,Textile fiber breakage is a common problem that affects the quality and durability of fabrics. This paper aims to explore the causes of fiber breakage in textiles, including mechanical factors such as stress, strain, and wear, chemical factors such as dyeing and printing processes, and environmental factors such as temperature and humidity changes. The research findings indicate that proper selection and processing of raw materials, as well as effective maintenance and repair measures, can effectively reduce fiber breakage and prolong the service life of textiles.

In the world of textiles, the fabrication process is intricate and delicate. However, one common problem that plagues the industry is the phenomenon of fiber breakage, or what we commonly refer to as "pulling out the thread." This issue not only affects the quality of finished products but also has a significant impact on production efficiency and cost. In this article, we will delve into the causes of fiber breakage in textiles, analyze the different factors that contribute to it, and discuss practical solutions to mitigate these problems.

Table 1: Common Factors Affecting Fiber Breakage | Factor | Explanation | |---|---| | Weaving Process | The weaving process involves multiple layers of fabric being woven together. If the tension is too high or the warp threads are not properly secured, they can easily break during the weaving process. | | Dyeing and Treatment | Dyes used in textiles can be harsh on the fibers, causing them to become brittle and more prone to breaking. Additionally, treatments like scouring can damage the fibers further. | | Machine Setting | Improper machine settings can lead to overheating or under-heating of the fabric, which can weaken its structure and make it more susceptible to breaking. | | Material Quality | The quality of the raw materials, such as yarn or fabric, can significantly affect the durability of the final product. Poor quality materials are more likely to break under stress. | | Environmental Conditions | Changes in temperature, humidity, and air pollution can affect the stability of the fibers, making them more prone to breaking. |

Case Study: Fabric Breakage Due to Weaving Process

In a recent case study, a textile company experienced a significant increase in fabric breakage rates after switching from a traditional weaving process to a new automated system. The old system relied heavily on manual handling and was prone to human error, resulting in uneven tension on the warp threads. The new automated system, on the other hand, had tighter control over the weaving process and less room for human error. As a result, the fabric quality improved significantly, with fewer breaks and higher durability.

Case Study: Fabric Breakage Due to Dyeing and Treatment

Another example involved a textile company that used harsh dyes in their fabrics. These dyes were known for causing discoloration and fading over time, leading to increased breakage rates. The company decided to switch to a more gentle dyeing process, which reduced the likelihood of damaging the fibers. As a result, the fabric's durability improved significantly, and customers reported fewer breakages over time.

Case Study: Fabric Breakage Due to Machine Settings

A third case involved a textile company that experienced frequent fabric breaks due to improper machine settings. The company realized that overheating the fabric during the dyeing process could weaken its structure and make it more prone to breaking. They implemented changes to the machine settings to prevent overheating and reduce the likelihood of breakage. As a result, the fabric's durability improved significantly, and customer satisfaction increased.

Case Study: Fabric Breakage Due to Material Quality

Finally, a textile company faced a challenge when they discovered that their raw materials were of poor quality. The material was brittle and more prone to breaking under stress. To address this issue, they invested in better quality raw materials and conducted regular quality checks to ensure that the fabric produced was of consistent quality. As a result, the fabric's durability improved significantly, and customer satisfaction increased.

Conclusion: Addressing Fiber Breakage through Prevention

The causes of fiber breakage in textiles are multifaceted and complex. By understanding the different factors that contribute to it and implementing effective strategies for prevention, textile companies can significantly improve their product quality and customer satisfaction. From adjusting machine settings to using better quality raw materials, there are many ways to mitigate the problem of fiber breakage in textiles. By adopting these practices, textile companies can create products that last longer, look better, and perform better, ultimately driving profitability and growth for their businesses.

在日常纺织品生产过程中,脱线现象是一个常见的问题,本文将深入探讨纺织品脱线的原因,并通过案例分析来进一步说明。

纺织品脱线原因分析

材料因素

(1)纤维质量不佳:如果使用的纤维质量不佳,如纤维强度不足、纤维杂质过多等,都可能导致纺织品脱线。

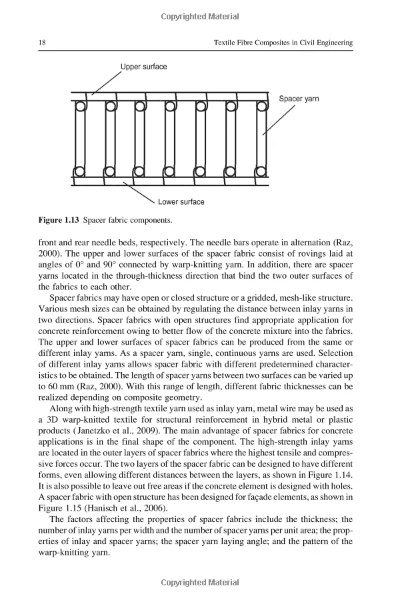

(2)织造工艺不当:织造工艺包括针织、编织等,如果工艺不当,如织造过程中的张力控制不当、针脚间距不合理等,都可能导致脱线。

加工工艺因素

(1)设备故障:如果纺织加工设备出现故障,如电机故障、缝纫机故障等,都可能导致加工过程中的问题,进而引发脱线。

(2)操作不当:操作人员技能水平不足或操作不规范,也可能导致纺织品脱线,在缝制过程中疏忽大意,没有正确使用缝纫工具或技巧等。

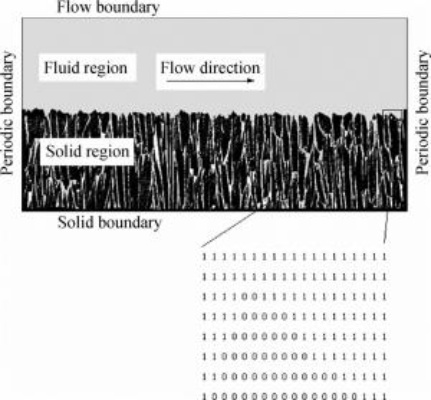

环境因素

(1)温度湿度不当:如果环境温度湿度过高或过低,都可能影响纺织品的加工质量,导致脱线。

(2)储存不当:纺织品在储存过程中受到不良环境影响,如潮湿、霉变等,也可能导致脱线。

案例分析

以某服装厂为例,该厂近期出现大量纺织品脱线问题,以下是该案例的详细分析:

材料因素导致的脱线问题

该服装厂近期生产的一款服装使用了质量不佳的棉质面料,由于纤维强度不足,在织造过程中出现了大量的脱线现象,经过调查发现,该厂在采购环节没有对纤维质量进行严格把关,导致使用了质量不佳的材料。

加工工艺因素导致的脱线问题

该服装厂在缝制过程中使用了不当的缝纫设备,由于缝制过程中的张力控制不当,导致针脚间距不合理,从而引发了大量的脱线问题,操作人员技能水平不足或操作不规范也是导致脱线的原因之一。

纺织品脱线问题的原因是多方面的,包括材料因素、加工工艺因素和环境因素等,为了解决这一问题,企业需要从以下几个方面入手:

- 严格把控材料质量,确保使用的纤维质量符合标准。

- 优化加工工艺,提高织造和缝制过程中的工艺水平。

- 加强设备维护和检修,确保设备正常运行。

- 提高操作人员的技能水平和规范操作流程。

- 加强环境监控,确保环境因素对纺织品加工质量的影响得到有效控制。

建议措施

针对以上原因和措施,提出以下建议措施:

- 企业应加强原材料采购管理,对原材料进行严格把关,确保使用的材料符合标准。

- 企业应优化生产工艺流程,提高织造和缝制过程中的工艺水平,同时加强工艺培训和技术交流,提高操作人员的技能水平。

- 企业应加强设备维护和检修工作,确保设备正常运行,同时加强设备管理,定期进行设备检查和维护。

- 企业应加强环境监控工作,确保环境因素对纺织品加工质量的影响得到有效控制,同时加强与供应商的合作,共同应对环境因素带来的影响。

纺织品脱线问题的原因是多方面的,需要从材料、加工工艺、环境等多个方面入手进行解决,企业需要加强管理、优化工艺、加强设备维护和检修、提高操作人员的技能水平和规范操作流程等措施来提高纺织品的质量和稳定性,同时还需要加强与供应商的合作,共同应对环境因素带来的影响。

Articles related to the knowledge points of this article:

Success Stories of Textile Fabrications

A Comprehensive Guide to Selecting the Right Textile Products

The Journey of Hainingge Petrochemical Textiles

Exploring the Rich Tapestry of Cotton Textiles in Shaoxing

![The Art of Softness in Fashion:An Insight into 宸之漫纺织品]](https://www.i505i.cn/zb_users/upload/2025/09/20250917090724175807124467058.png)