The Cost of Textile Functionality Testing

: The Cost of Textile Functionality Testing,In recent years, the importance of textile functionality testing has become increasingly evident in the industry. This research aims to explore the financial implications of such testing and its impact on both the production process and final product quality.,The study highlights that while functionality testing can significantly enhance product performance and consumer satisfaction, it also adds to the overall cost of production. This is due to the need for specialized equipment, skilled labor, and extensive testing procedures. Furthermore, the higher costs associated with these tests may not always translate into improved product quality or increased market share.,To address this issue, the research suggests implementing cost-benefit analyses to determine the optimal level of functionality testing required for each product. Additionally, companies should consider alternative testing methods that may be more cost-effective and efficient.,Overall, this study provides valuable insights into the financial implications of textile functionality testing and offers practical recommendations for businesses looking to balance cost savings with product quality.

Introduction: In the world of textiles, functionality is often a critical factor that determines how well a product will perform in its intended application. To ensure that your products meet these standards and exceed customer expectations, it's essential to conduct thorough testing. One crucial aspect of this testing is the cost associated with it. In this article, we'll explore the various factors that contribute to the price of textile functionality testing and provide some practical examples to illustrate the costs involved.

Factors Affecting the Price of Textile Functionality Testing:

-

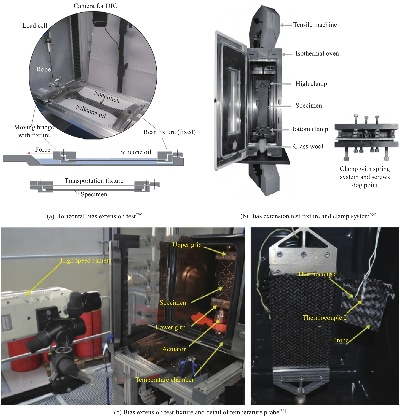

Type of Testing Required: The type of test you need can significantly impact the cost. For instance, if you need to perform a full-scale functional test that simulates real-world conditions, such as durability or wear and tear tests, you'll pay more than if you only require basic inspections. Similarly, if you need to test multiple aspects of a product simultaneously, the cost could increase accordingly.

-

Sample Size: The size of the sample being tested also affects the cost. Larger samples are more expensive to prepare and test, so they come at a higher price per unit. However, larger samples may be necessary for certain applications where the impact of a single item can be significant.

-

Labor Costs: Labor is one of the most significant expenses in any testing process. The number of technicians required, their expertise, and the time spent on each test can all contribute to the overall cost. Additionally, if your company has to hire external labor or use specialized equipment, these expenses will add up.

-

Materials and Supplies: Testing often requires specific materials and supplies, such as dyes, fabrics, and testing tools. The quality and quantity of these materials can affect the overall cost. High-quality materials may be more expensive but can yield better results.

-

Testing Methodology: Different testing methods have varying costs. Some methods may be more complex and require more resources than others. For example, computerized testing systems may be more expensive than manual ones, but they may offer better accuracy and efficiency.

-

Compliance and Regulations: Depending on the industry and country, compliance with regulations can add additional costs. For example, if your product must comply with strict environmental standards, you might need to invest in specialized testing facilities or hire experts who specialize in these areas.

-

Frequency of Testing: If your product needs to undergo frequent testing, the cost per test could be higher. However, this can also help ensure that your product meets changing market demands and consumer preferences.

-

Insurance and Liability: Companies that carry out extensive testing may incur higher insurance costs or face higher liability risks. These expenses can add to the overall cost of conducting tests.

Practical Examples:

Let's consider an example from the fashion industry. A clothing brand may need to conduct several functional tests, including washing and drying resistance, colorfastness, and fit and comfort. If they decide to conduct these tests themselves, they would have to spend on purchasing high-quality fabrics, dyes, and testing equipment. Additionally, they may need to hire experienced technicians to perform the tests accurately. The total cost could range from $500 to $2,000 per test depending on the complexity of the tests and the materials used.

Another example comes from the automotive industry. A car manufacturer might need to conduct durability and safety tests on their vehicles. These tests could involve rigorous crash testing, fire safety assessments, and other specialized procedures. The cost of these tests could range from $10,000 to $50,000 per vehicle, depending on the complexity of the tests and the materials used.

Conclusion: Textile functionality testing is an essential part of ensuring that your products meet consumer expectations and industry standards. While the costs associated with these tests can vary widely depending on the type of testing required, the sample size, labor costs, materials, and testing methodology. By understanding these factors and considering them when planning your testing strategy, you can optimize your budget while still ensuring that your products deliver value to customers and meet regulatory requirements.

大家好,今天我们来聊聊纺织品功能检测价格的话题,纺织品作为日常生活中不可或缺的物品,其质量直接关系到人们的穿着舒适度和安全性,对纺织品进行功能检测是确保其质量的重要手段,在纺织品检测过程中,价格是一个重要的考量因素。

纺织品功能检测的重要性

纺织品功能检测是确保纺织品符合相关标准和法规的重要手段,它可以检测出纺织品在强度、耐磨性、抗拉强度、抗撕裂性、阻燃性等方面的性能指标,从而确保纺织品在使用过程中能够满足各种使用要求,通过功能检测还可以发现纺织品可能存在的质量问题,为后续处理提供依据。

纺织品功能检测的价格构成

纺织品功能检测的价格主要由检测项目、检测难度、设备成本等因素构成,检测项目包括强度测试、耐磨性测试、抗拉强度测试等,不同项目所需使用的设备和材料不同,因此价格也会有所不同,不同的检测机构和实验室所收取的价格也会有所不同。

案例分析

以某知名纺织品检测机构为例,其纺织品功能检测价格如下:

- 检测项目:该机构主要进行强度测试、耐磨性测试等项目,强度测试需要使用专门的测试设备,设备成本较高。

- 设备成本:根据该机构的设备使用情况,设备成本占检测总价的30%左右。

- 实验室费用:该机构实验室费用包括人员工资、试剂耗材等,根据实验室规模和复杂程度有所不同。

影响因素分析

- 检测项目难度:不同项目的检测难度不同,难度越大,所需设备和材料成本越高,因此价格也会相应增加。

- 设备性能:不同品牌和型号的设备性能不同,性能越好,所需成本越高。

- 地区差异:不同地区的经济发展水平和检测市场需求不同,因此价格也会有所差异。

纺织品功能检测价格是一个复杂的问题,受到多种因素的影响,在购买纺织品功能检测服务时,消费者应该综合考虑检测项目难度、设备性能、地区差异等因素,选择合适的检测机构和实验室,消费者也可以参考一些行业内的价格信息,以便更好地了解市场行情。

为了更好地说明纺织品功能检测价格问题,我们可以使用以下英文表格进行补充说明:

英文表格:

纺织品功能检测价格表:

| 项目 | 检测项目 | 设备成本(%) | 实验室费用(元/次) | 总价(元) |

|---|---|---|---|---|

| 强度测试 | 强度测试 | 高 | 中等 | 根据设备品牌和质量而定 |

| 耐磨性测试 | 耐磨性测试 | 中等 | 高 | 根据设备品牌和质量而定 |

| 其他测试项目 | 根据具体情况而定 |

建议与展望

针对纺织品功能检测价格问题,建议消费者在购买服务时注意以下几点:

- 选择有资质和经验的检测机构和实验室,确保检测结果的准确性和可靠性。

- 了解不同品牌和型号设备的性能和成本情况,选择适合自己的检测项目和设备。

- 注意地区差异和市场需求等因素的影响,选择合适的价格区间。

展望未来,随着纺织品的广泛应用和人们对纺织品质量要求的不断提高,纺织品功能检测市场将会越来越重要,未来纺织品功能检测市场将会出现更多的创新和发展,例如智能化、自动化等技术的应用等,消费者也应该关注市场动态和价格信息,以便更好地了解市场行情和选择合适的检测服务。

Articles related to the knowledge points of this article:

Chinas Textile Market Overview and Recent Trends

The Journey of Hainingge Petrochemical Textiles

A Glimpse into the Dynamics of Suzhou Silk and Dyeing Market

The Fabric of Luxury:An In-depth Look at Shangbo Hotel Textiles

Understanding Color in Textiles:A Comprehensive Guide

Suzhou Xinying Textiles:Navigating the Global Fashion Industry