Understanding the Duties of a Textile Product Quality Assurance Team

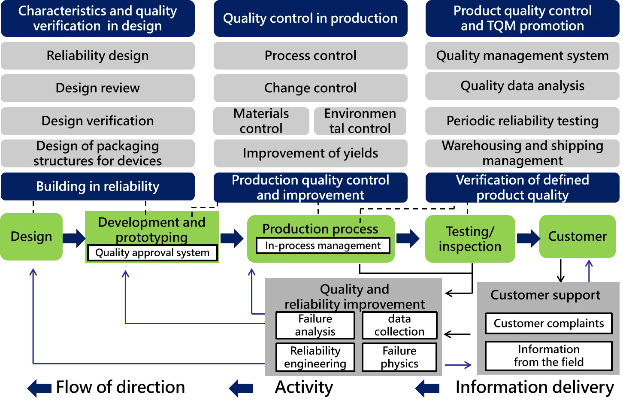

The textile product quality assurance team is responsible for ensuring the quality of the products being produced. This includes testing the raw materials, monitoring the production process, and inspecting the finished products. The team works closely with suppliers to ensure they are using only high-quality materials. They also work with customers to understand their needs and requirements. Failure to meet these responsibilities can result in poor quality products that may harm the reputation of the company.

Introduction: The textile industry is one of the most complex and demanding in the world, involving a wide array of materials, processes, and standards. This industry relies heavily on quality assurance, as poor-quality textiles can result in significant losses for both manufacturers and customers. Therefore, ensuring that textile products meet high standards of quality is crucial to maintaining brand reputation and customer satisfaction. In this article, we will discuss the responsibilities of a textile product quality assurance team and how they can contribute to the success of the industry.

Responsibilities of a Textile Product Quality Assurance Team:

- Inspection: The primary responsibility of a textile product quality assurance team is to inspect the raw materials and final products for any defects or flaws. This includes checking the thickness, color consistency, texture, and overall appearance of the fabric.

- Testing: To ensure that the products meet the desired quality standards, the team should conduct various tests on the textiles, such as strength tests, tear tests, wash tests, and dye tests. These tests help to identify areas where the product may need further improvement or adjustments.

- Documentation: Once the inspection and testing are complete, the team should document the results in detail, including any defects found and the recommended actions for correction. This documentation serves as a record of the inspection and testing process and ensures that all parties involved have accurate information about the product's quality status.

- Quality Control: The goal of the quality assurance team is to maintain consistent levels of product quality throughout the entire manufacturing process. They must monitor the progress of the production line and take corrective action if there are any issues that may affect the final product.

- Risk Management: A quality assurance team should be proactive in identifying potential risks and implementing strategies to mitigate them. This can include monitoring trends in market demand for different types of textiles and adjusting production schedules accordingly.

- Training and Education: It is essential for the team to stay up-to-date with the latest techniques and technologies in the textile industry. This includes attending industry conferences, reading industry publications, and taking continuing education courses. By staying informed, the quality assurance team can provide their colleagues with the knowledge and skills needed to improve overall product quality.

Case Study: In 2019, a major textile manufacturer experienced a significant quality issue with a popular line of shirts. The company had been receiving complaints from consumers about the fabric being too thin and not meeting the expected durability standards. The textile product quality assurance team was immediately tasked with investigating the issue and determining the root cause.

The team conducted a thorough inspection of the raw material used in the production process and compared it to the required specifications. They also analyzed the manufacturing process and identified any potential sources of error that could have contributed to the thin fabric. After conducting extensive testing, the team confirmed that the issue was indeed due to an improperly adjusted machine that was causing the fabric to become weaker over time.

To address this problem, the team recommended several improvements, including redesigning the machine settings and implementing new quality control measures. Additionally, they recommended conducting more frequent testing and monitoring to ensure that any changes implemented were effective and did not lead to further issues.

The manufacturer implemented these recommendations, and within six months, the problem had completely resolved. The quality of the shirts improved significantly, leading to a rise in customer satisfaction and positive reviews for the brand.

Conclusion: The textile product quality assurance team plays a crucial role in ensuring the success of the industry. By inspecting, testing, documenting, and maintaining consistent quality standards throughout the manufacturing process, these teams help to prevent costly mistakes and maintain consumer trust. With careful attention to detail and a commitment to continuous improvement, textile companies can achieve outstanding quality outcomes while still keeping pace with evolving market demands.

在纺织品行业,发货检验是确保产品质量和交货期的重要环节,本报告将详细阐述纺织品发货检验的职责,并结合实际案例进行说明。

纺织品发货检验职责概述

- 检验目标:确保纺织品在发货前符合质量标准,满足客户需求。

- 岗位职责: (1)负责纺织品进货验收,确保原材料、辅料等符合质量要求。 (2)负责纺织品出货前检验,确保产品符合相关标准。 (3)负责处理发货过程中的质量问题,提出改进措施。 (4)负责与供应商、物流公司等相关方沟通协调,确保货物运输安全、准时。

具体职责说明

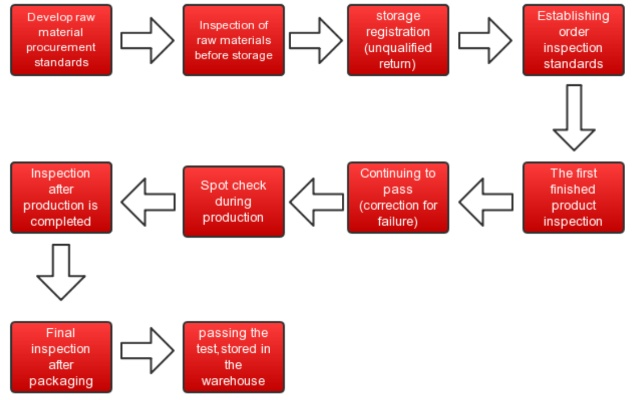

进货验收

(1)严格把关进货原材料、辅料的质量,确保符合国家相关标准和客户要求。 (2)对进货原材料、辅料进行抽检,确保数量和规格符合要求。 (3)对进货记录进行整理归档,确保进货信息可追溯。

出货前检验

(1)按照相关标准对纺织品进行全面检查,包括外观质量、尺寸规格、功能性等。 (2)对检验中发现的问题,及时通知供应商或相关部门进行处理。 (3)对检验结果进行统计分析,为后续生产提供数据支持。

处理质量问题

(1)对于发货过程中出现的质量问题,及时与供应商沟通协调,共同制定解决方案。 (2)对于无法解决的重大质量问题,及时向上级领导汇报,寻求帮助和支持。 (3)对于轻微质量问题,可采取返工、补救等措施进行处理。

实际案例说明

以某纺织品公司为例,其发货检验的职责和实际案例如下:

进货验收案例分析

某纺织品公司从国内采购了一批高质量的纺织品原料,经过严格的质量把关和抽检,确保原材料符合国家相关标准和客户要求,在进货过程中,公司还建立了完善的进货记录和档案管理制度,确保进货信息的可追溯性,公司还与供应商建立了良好的沟通协调机制,确保货物运输安全、准时。

出货前检验案例分析

某纺织品公司在出货前进行了全面的检验工作,公司按照相关标准对纺织品进行了全面检查,包括外观质量、尺寸规格、功能性等,在检查过程中,发现了一批尺寸规格不准确的产品,立即通知供应商进行处理,经过协商和改进措施的实施,最终解决了问题并保证了产品质量,公司还对检验结果进行了统计分析,为后续生产提供了数据支持。

结论与建议

纺织品发货检验的职责包括严格把关进货原材料、辅料的质量,确保产品质量符合相关标准;全面检查纺织品出货前的情况,确保产品符合相关标准;及时处理发货过程中的质量问题等,在实际工作中,应注重与供应商、物流公司等相关方的沟通协调,确保货物运输安全、准时,还应加强员工培训和学习,提高员工的专业素质和技能水平,建议相关部门加强监管和检查力度,确保纺织品发货检验工作的质量和效率。

Articles related to the knowledge points of this article:

Shanghai Textile Expo:A Visual Introduction

Boost Your Fashion Style with Top Export Textiles from Zhejiang

Hainans Textile Industry Boosts Promotion with Price Incentives