The International Standard for Textile Quality Control

: The International Standard for Textile Quality Control,Abstract:,The International Standard for Textile Quality Control (ISO 19084) is a globally recognized standard that aims to provide uniform criteria and guidelines for textile quality control. This standard was developed by the International Organization for Standardization (ISO), which is responsible for setting standards for various industries worldwide. The ISO 19084 standard covers various aspects of textile quality control, including testing methods, sampling techniques, and acceptance criteria. It provides a comprehensive framework for assessing the quality of textile products, ensuring consistency and reliability in quality control processes. The adoption of this standard has helped to improve the overall quality of textile products, enhance consumer confidence, and promote fair trade practices.

Introduction to Textile Quality and Its Impact on Brand Image

Textiles, the fabric of our daily lives, are an integral part of our economy. They not only provide warmth and comfort but also contribute significantly to our fashion sense and aesthetic appeal. However, the quality of these textiles is often overlooked in the rush to meet market demands. Poor quality can lead to health hazards, reduced product lifespan, and ultimately, a damaged brand image. In this article, we will explore the importance of textile quality control and how it affects the global textile industry.

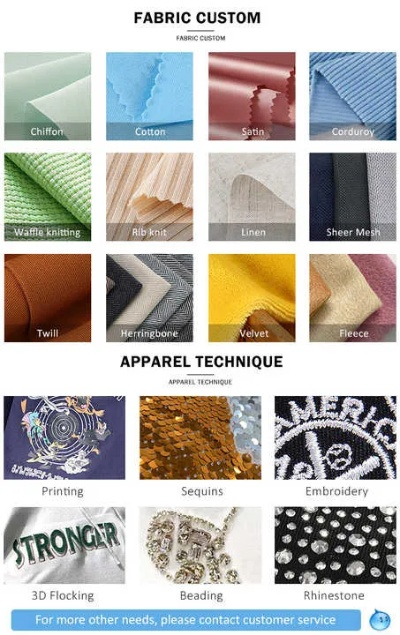

Textile Quality Control Standards

The International Organization for Standardization (ISO) has established standards for textile quality control that aim to ensure consistent product performance across different regions and manufacturing processes. These standards cover aspects such as color accuracy, pattern fidelity, shrinkage, and durability. For example, the ISO 26860 standard specifies the requirements for measuring and controlling the color uniformity of woven fabrics.

Quality Control in Practice

In practice, textile manufacturers must adhere to these standards to maintain their competitive edge in the market. One way to achieve this is through the use of advanced quality control technologies such as automated dyeing machines, computer-controlled printing presses, and precision cutting equipment. These tools enable manufacturers to produce high-quality products with greater consistency and efficiency.

However, even with the best technology, there will always be instances where products fail to meet the standards set by the ISO or other relevant international organizations. This is where the concept of "textile quality control" comes into play. It involves monitoring and analyzing the production process, identifying potential issues early on, and taking corrective action to prevent any further defects from being produced.

For instance, consider the case of a manufacturer who produces high-end silk scarves using traditional hand-dyeing techniques. Despite employing experienced artisans and strict quality control measures, some scarves were found to have uneven dyeing patterns or loose threads. This led to a decline in customer satisfaction and a loss of reputation for the brand.

To address this issue, the manufacturer implemented a more rigorous quality control system, including regular training for all staff members involved in the production process, stricter inspection protocols, and the use of automated testing equipment. As a result, the number of defective scarves dropped significantly, and the overall quality of the product improved.

Impact of High Quality Textiles on Brand Image

The impact of high-quality textiles on a brand's image cannot be overstated. A positive brand image enhances consumer trust, loyalty, and willingness to pay a premium for the product. On the other hand, poor quality can quickly turn off customers, leading to negative reviews, loss of sales, and ultimately, financial losses for the company.

For example, consider the case of a well-known clothing brand that was known for producing high-quality, durable clothing. However, due to poor quality control practices, one season saw a significant increase in complaints about thread breakage and wear and tear. These issues led to a decline in sales and a loss of market share for the brand.

Conversely, when a brand invests in quality control and consistently delivers high-quality products, it builds trust with customers and establishes itself as a reputable brand. This trust is essential for long-term success as customers become loyal to the brand and continue to purchase its products even during times of economic uncertainty.

Conclusion

In conclusion, textile quality control is crucial for maintaining a brand's image and ensuring customer satisfaction. By implementing effective quality control systems and continuously monitoring and improving production processes, companies can produce high-quality products that deliver value to consumers. In the competitive global textile industry, this approach is not only beneficial for individual companies but also for the industry as a whole.

纺织品次品率国标概述

纺织品作为日常生活中不可或缺的物品,其质量直接关系到人们的日常生活和身体健康,为了确保纺织品的质量和安全,各国都制定了相应的国家标准,纺织品次品率国标是衡量纺织品质量的重要指标之一。

纺织品次品率国标的内容与标准

纺织品次品率国标主要包括以下几个方面:

- 纺织品原材料的质量要求:纺织品必须使用符合国家标准的原材料,以确保其质量。

- 纺织品的检验与检测:纺织品必须经过严格的检验与检测,确保其符合国家标准。

- 纺织品的次品率标准:根据不同类型和用途的纺织品,其次品率标准也有所不同,对于服装类纺织品,次品率应控制在一定范围内,以确保消费者的权益和安全。

纺织品次品率国标的实施与案例分析

在实际操作中,纺织品次品率国标得到了广泛的应用,以下是一个具体的案例说明:

某国家纺织品质量标准实施情况

该国家在纺织品质量标准方面非常严格,制定了详细的国家标准,该标准涵盖了纺织品原材料的质量要求、纺织品的检验与检测等方面,该国家还建立了完善的检测机构,对纺织品进行严格的检验与检测。

在实际应用中,该国家的一些知名品牌纺织品在市场上获得了良好的口碑,某品牌的服装面料采用了高质量的原材料,经过严格的检验与检测,其次品率非常低,消费者对该品牌的纺织品质量非常认可,认为其穿着舒适、耐用。

纺织品次品率国标的重要性与意义

纺织品次品率国标的重要性与意义在于保障消费者的权益和安全,维护市场秩序,它也是推动纺织行业健康发展的重要手段,通过制定严格的国家标准,可以规范纺织品的生产、销售和流通环节,提高纺织品的品质和安全水平。

纺织品次品率国标是衡量纺织品质量的重要指标之一,在实际操作中,各国都制定了相应的国家标准,以确保纺织品的品质和安全,通过实施严格的检验与检测,可以确保纺织品的次品率符合国家标准,保障消费者的权益和安全,它也是推动纺织行业健康发展的重要手段,我们应该加强纺织品的监管和检测工作,提高纺织品的品质和安全水平,为消费者提供更好的产品和服务。

Articles related to the knowledge points of this article:

Silk Pillowcases and Bedding:The Art of Comfort for a Better Nights Sleep

Navigating the Complexities of Textile Warehouse Design

Fabric Testing in Wuxi A Journey Towards High-Quality Textiles