Understanding and Managing Textile Shrinkage:A Comprehensive Guide

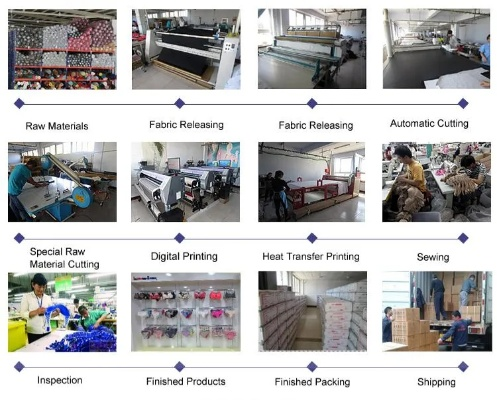

This comprehensive guide aims to provide a thorough understanding and management of textile shrinkage. Textile shrinkage refers to the phenomenon whereby textile materials, such as fabrics, shrink in size when they are exposed to heat or chemicals. This can result in undesirable changes in the appearance and functionality of the product.,The first step in managing textile shrinkage is to understand its causes. Common causes include improper processing, exposure to high temperatures, and the use of certain chemicals. Once the cause is identified, appropriate measures can be taken to mitigate the problem.,One effective method is to pre-treat the textile material with a shrinkage-resistant agent before it is subjected to any heat or chemical treatment. Additionally, proper storage conditions should be maintained to prevent further shrinkage.,In conclusion, this guide provides a comprehensive overview of textile shrinkage and offers practical tips on how to manage and minimize its impact. By following these steps, businesses can ensure that their products maintain their desired quality and performance.

Introduction: Textile shrinkage is a common issue that affects the quality and appearance of garments made from fabric. This phenomenon occurs when the fabric contracts or contracts due to moisture, heat, or chemicals, causing it to become smaller in size. In this guide, we will explore the causes of textile shrinkage, its impact on garments, and strategies for managing it effectively. We'll also provide an overview of the American Standard Test Method (ASTM) for measuring shrinkage and offer practical examples to demonstrate how to apply these principles in real-world situations.

Causes of Textile Shrinkage: Shrinkage can be attributed to several factors, including:

-

Moisture Content: High moisture content in the fabric increases its tendency to shrink. Excessive exposure to water, steam, or humidity can cause the fibers to contract, leading to reduced size.

-

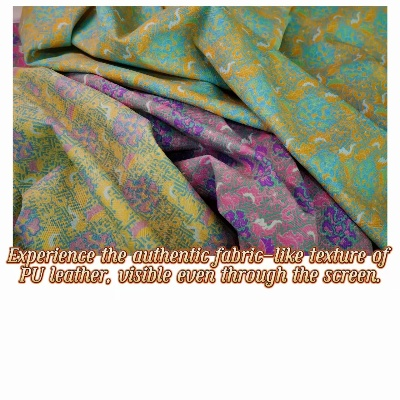

Chemicals: Chemical treatments such as dyeing, printing, and finishing processes can cause shrinkage by altering the fabric structure. For instance, some dyes may cause the fabric to shrink more than usual during washing or drying.

-

Heat Treatments: High temperatures during processing, such as knitting or weaving, can cause the fabric to shrink. This is particularly true for natural fibers like cotton, which tend to expand at high temperatures.

-

Fabric Type: Different fabric types have varying degrees of shrinkage. Wool and silk, for example, are known for their low shrinkage rate compared to synthetic materials like polyester or nylon.

-

Fabric Structure: The way the fabric is woven or knitted can affect its shrinkage. Patterned or intricate designs often result in increased shrinkage due to the interlocking of warp and weft threads.

Impact of Textile Shrinkage on Garments: The extent of shrinkage can significantly affect the fit, comfort, and appearance of garments. Here are some potential consequences:

-

Fit Issues: Shrinkage can cause clothes to fit differently after washing and wearing. This can lead to discomfort or even loss of shape over time.

-

Color Distortion: Shrinkage can cause clothing to lose color intensity or fade faster than expected. This is particularly noticeable in garments with delicate colors or patterns.

-

Durability: Excessive shrinkage can weaken the fabric, making it more prone to wear and tear.

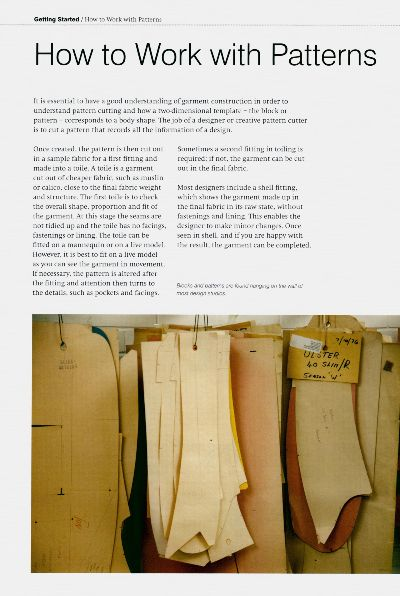

Managing Textile Shrinkage: To minimize the impact of shrinkage on garments, manufacturers can implement various strategies. Here are some recommended practices:

-

Proper Care Instructions: Include detailed care instructions in product descriptions that highlight the importance of avoiding high heat settings during washing and drying, as well as proper ironing techniques.

-

Choosing Fabrics: When selecting fabrics for garments, consider those with lower shrinkage rates, especially for items that need to maintain their shape or appearance over time.

-

Correct Washing and Drying Methods: Follow the care instructions provided with the garment to ensure that it is washed and dried at appropriate temperatures and without excessive exposure to water or chemicals.

-

Use of Detergents: Choose detergents that are designed for specific fabrics, as some can cause excessive shrinkage. Look for products that are labeled "low shrink" or "non-stretch."

-

Ironing Techniques: Use a hot iron set to a medium temperature and a low setting to avoid excessive heat that could further shrink the fabric. Also, use a pressing cloth or pad to help distribute the heat evenly across the fabric.

-

Seasonal Changes: Consider seasonal variations in fabric shrinkage when designing garments. For example, summer fabrics may require less shrinkage than winter fabrics, so they may need fewer washes or shorter drying times.

Case Study: Consider the following scenario: a manufacturer of men's shirts was experiencing significant shrinkage issues with their latest collection. Upon investigation, they discovered that the fabric used in many of the shirts had been exposed to high heat during the knitting process. To address this problem, the manufacturer implemented a new process that involved using a lower temperature setting during knitting and implementing stricter guidelines for handling and washing the fabric. As a result, the shrinkage rate decreased significantly, and the company received positive feedback from customers who appreciated the improved quality of their garments.

Table: Example of Shrinkage Rates for Different Fabric Types

| Fabric Type | Shrinkage Rate (%) |

|---|---|

| Cotton | 10-15 |

| Linen | 10-15 |

| Silk | 5-7 |

| Polyester | 10-15 |

| Nylon | 8-10 |

Conclusion: Textile shrinkage is an inevitable challenge for garment manufacturers, but with careful consideration and implementation of best practices, it can be managed effectively. By understanding the causes of shrinkage and taking proactive measures to reduce or prevent it, manufacturers can create garments that not only look good but also perform well over time. Remember, the key is to strike a balance between maintaining the desired fit and appearance while preserving the durability and longevity of the fabric itself.

在纺织品生产过程中,缩水率是一个重要的质量指标,它直接关系到纺织品的质量和性能,美标作为纺织品质量标准的重要参考,对于缩水率的控制有着严格的要求,本文将围绕纺织品缩水率美标展开讨论,并通过英文案例说明来进一步阐述。

美标对纺织品缩水率的要求

美标对纺织品缩水率有着明确的规定,根据美标规定,纺织品在生产过程中应保持一定的缩水率范围,以保证纺织品在后续使用过程中的稳定性和可靠性,缩水率过高或过低都可能影响纺织品的使用效果和寿命。

美标缩水率的具体数值

根据美标规定,纺织品缩水率的数值通常在一定的范围内波动,具体数值可能因不同的纺织品类型、生产工艺、环境条件等因素而有所不同,纯棉纺织品通常要求缩水率在±5%以内,而丝绸纺织品则可能需要更高的缩水率范围。

美标案例分析

为了更好地理解美标对纺织品缩水率的要求,我们可以结合一些具体的英文案例进行分析。

某品牌纯棉纺织品缩水率控制案例

该品牌在生产纯棉纺织品时,采用了先进的生产工艺和严格的质量控制措施,在生产过程中,严格控制温度、湿度等环境因素,确保纺织品在生产过程中的稳定性,采用了先进的缩水率检测设备,对纺织品进行实时监测,及时发现和处理缩水问题,该品牌生产的纯棉纺织品缩水率控制在±3%以内,满足了美标的要求。

某品牌丝绸纺织品缩水率控制案例

该品牌在生产丝绸纺织品时,采用了特殊的工艺流程和质量控制措施,在生产过程中,严格控制温度、湿度等环境因素的同时,还采用了特殊的防缩水处理技术,该品牌还建立了完善的检测体系,对丝绸纺织品的缩水率进行定期检测和评估,该品牌生产的丝绸纺织品缩水率达到了美标要求的范围之内。

美标对纺织品品质的影响

美标对纺织品品质的影响是多方面的,美标提高了纺织品的稳定性和可靠性,减少了在使用过程中的损坏和损失,美标提高了纺织品的外观和质量,使纺织品更加美观、舒适和耐用,美标也促进了纺织品的研发和创新,推动了纺织行业的发展。

提高纺织品缩水率的措施

为了降低纺织品缩水率,可以采取以下措施:

- 选用优质原材料:选择优质、环保、无害的原材料,减少缩水问题的发生。

- 严格控制生产工艺:采用先进的生产工艺和质量控制措施,确保纺织品在生产过程中的稳定性。

- 定期检测和维护:建立完善的检测和维护体系,及时发现和处理缩水问题。

- 培训员工:提高员工的质量意识和操作技能,确保纺织品生产过程中的质量可控。

纺织品缩水率美标是衡量纺织品质量的重要指标之一,通过了解美标对纺织品缩水率的要求、结合具体案例分析以及提高纺织品品质的措施等方面,我们可以更好地理解美标对纺织品生产的重要性,我们也应该采取相应的措施来降低纺织品缩水率,提高纺织品的品质和稳定性。

Articles related to the knowledge points of this article:

Explore the Textiles Industry in Shaoxing An In-depth Job Hunting Guide

The Dynamic Landscape of Tianjins Textile Prices

The Role of the National Textile Supervision and Testing Center

A Detailed Guide to Shopping at Yuers Textile Live Room