The Transformative Journey of Kaiyuan Textile Factory Construction

Kaiyuan Textile Factory Construction: A Journey of Transformation,The construction of Kaiyuan Textile Factory represents a significant transformation in the textile industry. The factory was established to produce high-quality, eco-friendly textiles that meet global standards. The journey began with a team of experienced professionals who were committed to creating a sustainable and innovative business model. They worked tirelessly to develop new technologies and processes that would enhance the production process while reducing waste and minimizing environmental impact.,As the factory progressed, it became clear that there were challenges along the way. However, the team remained resilient and determined to overcome these obstacles. They faced numerous setbacks, but each challenge only strengthened their resolve to succeed. Through perseverance and hard work, they were able to overcome these challenges and achieve their goals.,Today, Kaiyuan Textile Factory is a thriving business that produces high-quality, eco-friendly textiles that meet global standards. The factory's success can be attributed to the transformative journey it undertook during its construction. It is a testament to the power of determination, resilience, and hard work that can lead to great achievements.

Introduction: The dawn of a new era is often marked by the construction of landmark projects. For Kaiyuan Textile Factory, this journey began with an ambitious vision and a relentless pursuit of excellence. From the initial planning stages to the grand opening, the story of Kaiyuan's transformation is one of innovation, resilience, and unwavering commitment to quality. In this article, we will delve into the intricacies of Kaiyuan's construction journey, from its conception to its completion, and explore the lessons learned along the way.

Conceptualization: Kaiyuan Textile Factory was born out of a deep-seated desire to bring modern manufacturing techniques to the heart of China's textile industry. The visionaries behind the project envisioned a facility that would not only produce high-quality products but also set new standards for sustainability and environmental responsibility. With a team of experts in industrial design, engineering, and construction, they crafted a blueprint that reflected their mission - to create a factory that would not only meet but exceed customer expectations.

Design and Planning: The initial phase involved a meticulous process of designing the factory's layout, selecting materials, and determining energy-efficient systems. The team worked tirelessly to ensure that every aspect of the factory met the highest standards of efficiency, durability, and sustainability. They employed advanced computer-aided design (CAD) software to visualize the factory's structure and optimize its space-efficiency. Additionally, they incorporated green technologies such as solar panels and rainwater harvesting systems to reduce waste and minimize carbon footprint.

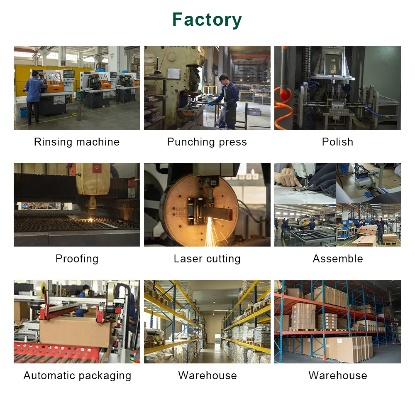

Construction: Once the design was finalized, the construction phase commenced. Kaiyuan's construction team was composed of skilled craftsmen who had years of experience in building similar facilities. They adhered to strict safety protocols and implemented innovative construction methods to ensure timely completion while minimizing disruption to the surrounding environment. The use of prefabricated components and modular design allowed for quicker assembly and easier maintenance.

Innovation: At Kaiyuan, innovation was not just a buzzword; it was a guiding principle. The factory incorporated cutting-edge technologies such as automated weaving machines, robotic assembly lines, and intelligent monitoring systems. These technological advancements not only increased productivity but also improved product quality and reduced errors. The use of digital data analytics also helped in predicting equipment failures and ensuring optimal operation of the entire production line.

Environmental Sustainability: Kaiyuan's commitment to sustainability extended beyond the factory itself. The company partnered with local authorities to recycle wastewater and convert excess heat generated by the factories into clean energy. The use of eco-friendly materials and processes further solidified the company's dedication to reducing its ecological footprint.

Case Study: Consider the example of Kaiyuan's partnership with a local garment retailer. The retailer needed a reliable supplier capable of delivering high-quality fabrics on time. Kaiyuan's commitment to sustainability and fast delivery led them to become the preferred choice for the retailer. The retailer's satisfaction not only boosted Kaiyuan's reputation but also contributed to the growth of the local economy. This case study highlights how Kaiyuan's commitment to sustainability has not only benefited the company but also positively impacted the broader community.

Conclusion: The construction of Kaiyuan Textile Factory stands as a testament to the power of visionary leadership, innovative thinking, and a commitment to excellence. From the initial conception to the grand opening, the journey was marked by a relentless pursuit of perfection, a dedication to sustainability, and a profound understanding of the importance of community engagement. As we look forward to the future, Kaiyuan's success story serves as an inspiration to all those who dare to dream big and work tirelessly towards achieving their goals.

背景介绍

随着工业化的不断推进,纺织行业作为国民经济的重要支柱产业,其建设与发展显得尤为重要,位于云南省开远市的纺织厂建设工作正如火如荼地进行中,本文将围绕这一主题,从多个角度进行深入探讨。

建设过程概述

项目背景

开远纺织厂的建设旨在提升当地纺织产业的整体水平,促进产业结构优化升级,该项目得到了政府的大力支持,并得到了社会各界的广泛关注。

建设步骤

(1)前期准备:包括土地规划、环境评估、施工图纸设计等。 (2)施工阶段:包括设备采购、原材料采购、施工队伍组建等。 (3)投产运营:预计在项目竣工后的一段时间内投入生产。

案例分析

为了更好地展示开远纺织厂建设的过程和成果,我们引入了一个具体的案例,该案例是一家大型纺织企业的转型升级项目,其成功之处在于科学规划、合理布局、高效管理等方面,通过该案例,我们可以看到纺织厂建设过程中的一些关键环节和注意事项。

建设中的关键环节

土地规划与选址

在土地规划与选址过程中,充分考虑了纺织厂的建设需求和当地环境条件,通过科学合理的规划,确保了纺织厂的建设符合环保、安全、高效的要求。

设备采购与安装

在设备采购与安装过程中,注重设备的品质和性能,确保了设备的先进性和可靠性,加强了对设备的安装和调试工作,确保了设备的正常运行。

施工管理与团队建设

在施工管理方面,注重团队的建设和管理,确保了施工进度和质量,加强了对施工现场的管理和安全保障工作,确保了施工过程中的安全和质量。

建设中的注意事项

- 环保与安全:在纺织厂建设中,必须严格遵守环保和安全法规,确保建设过程中的环保和安全措施得到有效落实,加强了对施工现场的管理和安全保障工作,确保施工过程中的安全和质量。

- 质量管理:在纺织厂建设中,必须注重质量管理,确保产品质量符合国家标准和客户要求,加强了对原材料的采购和使用管理,确保原材料的质量和来源可靠。

- 成本控制:在纺织厂建设中,必须注重成本控制,合理规划项目预算,降低建设成本,加强了对施工过程中的成本控制工作,确保建设成本得到有效控制。

英文案例说明(表格形式)

纺织厂建设案例分析

| 项目特点 | 建设情况 | 案例分析 |

|---|---|---|

| 企业背景 | 大型纺织企业 | 该企业经过转型升级,实现了产业升级和经济效益的提升 |

| 土地规划 | 科学规划 | 该企业充分考虑了当地环境条件和企业需求,进行了科学合理的土地规划 |

| 设备采购 | 设备品质与性能 | 该企业注重设备的品质和性能,采购了先进的设备 |

| 施工管理 | 团队建设与管理 | 该企业注重团队的建设和管理,确保了施工进度和质量 |

| 安全保障 | 安全措施落实 | 该企业在施工现场加强了安全管理措施的落实 |

| 质量保障 | 产品质量符合国家标准和客户要求 | 该企业在产品质量方面注重质量管理,确保产品质量符合国家标准和客户要求 |

| 成本控制 | 项目预算规划 | 该企业在项目建设中注重成本控制,合理规划项目预算 |

| 开远纺织厂建设取得显著成效 | 通过科学规划、合理布局、高效管理等方面的努力,开远纺织厂建设取得了显著成效 |

开远纺织厂的建设是一项重要的工程项目,它不仅关系到当地经济的发展和产业结构的优化升级,也关系到国家的经济安全和民生改善,在建设过程中,必须严格遵守环保、安全、质量等方面的法规和标准,注重环保与安全、质量管理、成本控制等方面的措施落实,确保建设工作的顺利进行和取得实效。

Articles related to the knowledge points of this article:

Strategies for Effective Management in a Textile Factory

The Dynamics and Innovations at Dunzhou Spray Water Textile Factory

Transforming the Industry:The Story of Gaomi Zhengda Textile Factory