The Role of Textile Testing in Quality Control in Zhejiang

In the process of textile quality control, textile testing plays an important role. Textile testing is a crucial part of the quality control process in Zhejiang, as it helps to ensure that the fabric meets the necessary standards and requirements. The test results provide valuable information about the fabric's performance, such as its strength, durability, and colorfastness. These tests are conducted to identify any defects or flaws in the fabric, allowing manufacturers to make necessary adjustments and improvements. By using appropriate textile testing methods, manufacturers can ensure that their products meet the highest standards and provide consumers with high-quality products. Therefore, it is essential for manufacturers to invest in textile testing equipment and personnel to ensure that their products meet the required standards and meet consumer expectations.

In the vibrant world of textile manufacturing, quality is paramount. Zhejiang, a province known for its rich cultural heritage and thriving economy, has been at the forefront of innovation and excellence in the textile industry. One of the key pillars of this success is the rigorous testing process that ensures every piece of fabric meets the highest standards. In this article, we delve into the importance of textile testing in Zhejiang and how it contributes to the overall quality control system.

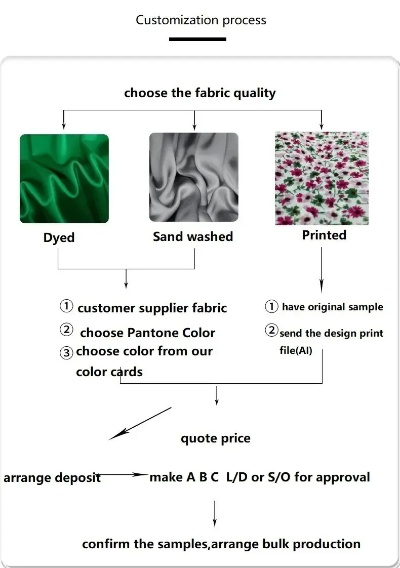

At the heart of any textile product is the fiber, which determines its texture, strength, and durability. To ensure these qualities are consistent across all products, Zhejiang employs a comprehensive testing protocol that covers various aspects of the textile industry. The first step is pre-treatment, where raw materials undergo a series of chemical treatments to enhance their performance. This includes bleaching, dyeing, and finishing processes that transform the fiber into a finished product.

Once the raw materials have been processed, they enter the production line. Here, the fibers are woven or knitted together to create the fabric. During this stage, several tests are conducted to ensure uniformity and consistency in the weave pattern. These include measuring the thickness, width, and length of the threads, as well as checking for defects such as holes or unevenness.

The next step is the dyeing process, where colors are applied to the fabric. This involves conducting tests to ensure the colorfastness of the dye, meaning it remains vibrant even after washing or exposure to sunlight. Additionally, the level of shrinkage during the dyeing process must be tested to ensure that the fabric does not warp or twist excessively.

After the dyeing process, the fabric is ready for finishing. This may involve additional treatments such as coating or printing, which can affect its appearance and functionality. Again, testing is crucial to ensure that these treatments do not compromise the fabric's integrity.

Finally, once the fabric is complete, it goes through a final inspection process. This includes visual checks for defects, measurements to verify dimensions, and testing to ensure compliance with industry standards. This final round of testing helps to identify any issues early on, before the product reaches the market.

In addition to these standard tests, Zhejiang also incorporates advanced techniques such as computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These tools enable manufacturers to create custom designs and optimize production processes, while still ensuring that each product meets strict quality standards.

One example of this approach can be seen in the case of a leading manufacturer in Zhejiang. They developed a CAD software that allowed them to design a new type of fabric with enhanced durability and breathability. Before mass production, they conducted extensive testing to ensure that the new design met all the required standards. This included tests for strength, flexibility, and resistance to wear and tear. Once satisfied with the results, they proceeded to manufacture the product using their state-of-the-art machinery.

Another example comes from a company specializing in eco-friendly textiles. They were concerned about the environmental impact of their products, so they implemented a zero-waste policy throughout the entire production process. This meant that they had to test every step of the process to ensure that no harmful chemicals or materials were used. From selecting sustainable raw materials to developing innovative dyeing methods, every aspect of their production was scrutinized for environmental responsibility.

In conclusion, textile testing in Zhejiang plays a critical role in ensuring that every piece of fabric produced meets high standards of quality and sustainability. By implementing a comprehensive testing protocol that covers every aspect of the production process, manufacturers can minimize errors and defects, ultimately resulting in a better end product for consumers. As the textile industry continues to evolve, the importance of testing will only continue to grow, enabling manufacturers to stay ahead of the competition and deliver exceptional products to customers around the world.

浙江作为中国的重要纺织产业基地,其纺织品的质量检测工作备受关注,本篇文章将围绕浙江纺织品检测的主题,通过英文口语化的方式,介绍相关检测流程、案例分析以及未来趋势。

浙江纺织品检测概述

检测流程

浙江纺织品检测主要包括以下几个环节:原料检验、过程控制、成品检验等,在原料检验阶段,主要对原材料的质量进行检测,确保其符合国家标准和客户需求,在过程控制方面,采用先进的检测设备和技术手段,对纺织生产过程中的各个环节进行严格控制,在成品检验阶段,采用多种检测方法,确保纺织品符合相关标准和客户要求。

案例分析

近年来,浙江地区的一些纺织品检测案例展示了其卓越的品质和检测能力,某知名品牌在浙江地区的纺织品检测中,采用了先进的检测设备和严格的质量控制体系,确保了产品的质量和安全性,还有一些其他案例,展示了浙江纺织品检测在不同行业和不同规模企业的应用情况。

检测技术与方法

检测技术

浙江纺织品检测主要采用以下几种技术:

(1)化学分析:通过化学分析方法对纺织品中的化学成分进行检测,确保其符合国家标准和客户需求。

(2)仪器分析:采用各种先进的仪器设备进行纺织品成分、结构、性能等方面的分析。

(3)微生物检测:对纺织品中的微生物进行检测,确保其符合相关标准和安全要求。

案例说明

在某知名品牌纺织品检测中,采用了先进的化学分析和仪器分析技术,对原材料和成品的化学成分、结构、性能等方面进行了全面检测,还采用了微生物检测方法,确保了产品的安全性和卫生性,还有一些其他案例,展示了不同行业和不同规模企业的纺织品检测情况。

未来趋势

技术创新与升级

随着科技的不断进步,浙江纺织品检测将更加注重技术创新和升级,将更加注重智能化、自动化、数字化等方面的技术应用,提高检测效率和准确性,还将加强与国际先进技术的交流与合作,引进先进的技术和设备,提高检测水平。

绿色环保与可持续发展

随着环保意识的不断提高,浙江纺织品检测也将更加注重绿色环保和可持续发展,将更加注重环保材料的使用和废弃物处理等方面的要求,推动纺织产业向绿色、环保、可持续方向发展,还将加强与行业协会和政府部门的合作,共同推动纺织品检测事业的发展。

浙江纺织品检测是保障纺织品质量和安全的重要手段,通过先进的检测技术和方法,以及严格的质量控制体系,浙江地区的纺织品质量得到了有效保障,随着科技的不断进步和环保意识的不断提高,浙江纺织品检测将更加注重技术创新和绿色环保等方面的发展,还将加强与国际先进技术的交流与合作,提高检测水平和服务质量。

Articles related to the knowledge points of this article:

An Analysis of Hubei Provinces Textile Export Performance