A Comprehensive Guide to Textile Fabric Testing Equipment

This comprehensive guide provides a detailed overview of textile fabric testing equipment, including their functions, specifications, and applications. The guide covers various types of testing equipment, such as tensile testers, elongation testers, tear testers, and abrasion testers, among others. It also discusses the importance of using appropriate testing equipment for accurate results and ensuring product quality. Additionally, the guide provides tips on how to select the right testing equipment for specific applications and how to maintain and use the equipment properly for optimal results. Overall, this guide is an essential resource for anyone involved in textile fabric testing and quality control.

Welcome to our guide on textile fabric testing equipment, where we will delve into the various tools and techniques used to ensure quality, durability, and compliance with industry standards. From simple handheld instruments to sophisticated computerized systems, this comprehensive overview will help you understand the importance of testing in the textile industry and how it contributes to the production process.

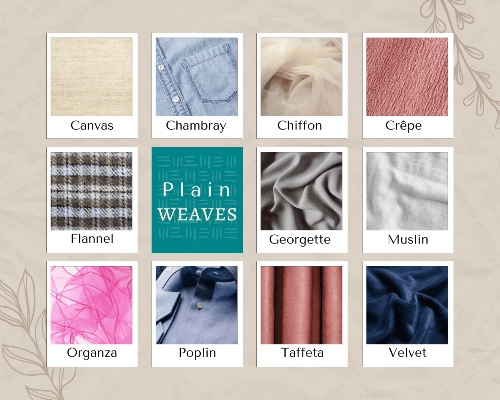

Textile fabric testing is an essential step in the manufacturing process that ensures the quality and consistency of finished products. It involves various methods such as visual inspection, mechanical tests, chemical analysis, and environmental assessment. The choice of testing equipment depends on the specific requirements of the textile product and the desired level of accuracy and precision. In this guide, we will explore the different types of testing equipment available and their applications in the textile industry.

Visual Inspection Tools

Visual inspection tools are the first line of defense for textile manufacturers. They help identify defects such as fraying, pilling, and color variations in raw materials or finished products. Some common examples include magnifying glasses, tweezers, and microscopes.

| Visual Inspection Tools | Description | Application |

|---|---|---|

| Magnifying Glasses | Used for close-up inspection | Identify small defects in raw materials or finished products |

| Tweezers | Used for delicate operations | Handle small objects or fragile samples |

| Microscopes | Used for detailed examination | Analyze intricate patterns or textures |

Mechanical Testing Equipment

Mechanical testing equipment is used to measure the strength, flexibility, and resistance to wear and tear of textile materials. These tools can be divided into two main categories: static and dynamic tests.

| Mechanical Testing Equipment | Description | Application |

|---|---|---|

| Tensile Testers | Measure the breaking strength of textiles | Assess the resilience of materials under tension |

| Burst Testers | Simulate bursting pressure | Determine the burst strength of fabrics |

| Tear Testers | Measure the tear strength of textiles | Evaluate the ability of materials to withstand tears |

| Scalpel Testers | Simulate cutting action | Assess the toughness of materials during fabrication |

Chemical Analysis Instruments

Chemical analysis is crucial for ensuring that textile fabrics meet specific chemical properties required by their intended use. This includes determining the presence of harmful substances, such as heavy metals, and assessing the overall chemical composition of the fabric.

| Chemical Analysis Instruments | Description | Application |

|---|---|---|

| Spectrophotometers | Used for measuring absorbance and transmittance | Identify colorants and other additives in fabrics |

| Gas Chromatography (GC) | Separates and analyzes complex mixtures of chemicals | Determine the composition of synthetic fibers or dyes used in fabrics |

| Electrophoresis | Separates molecules based on their electrical charge | Analyze the molecular structure of polymers used in fabrics |

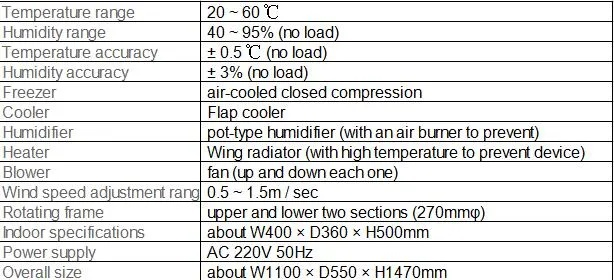

Environmental Testing Equipment

Environmental testing is essential for ensuring that textile products comply with regulations related to water pollution, air quality, and end-of-life disposal. This includes testing for toxic substances, biodegradability, and impact on the environment.

| Environmental Testing Equipment | Description | Application |

|---|---|---|

| Ecotoxicity Testers | Assess the potential harm caused by textiles to aquatic life | Ensure compliance with water pollution regulations |

| Biodegradability Testers | Determine the rate at which textiles decompose in landfills | Ensure compliance with waste management regulations |

| Acid Rain Testers | Simulate the effects of acidic rain on textiles | Ensure compliance with air quality regulations |

Digital Testing Equipment

Digital testing equipment has revolutionized the way textile fabrics are tested. These advanced tools use advanced technology to provide more accurate and efficient results than traditional methods.

| Digital Testing Equipment | Description | Application |

|---|---|---|

| Computerized Tensile Testers | Use computer algorithms to simulate real-world conditions | Provide more consistent results than manual testing |

| Automated Burst Testers | Perform multiple tests automatically and report results quickly | Simplify the testing process and reduce labor costs |

| Laser Scanning Systems | Create three-dimensional images of fabrics using laser technology | Allow for better understanding of complex patterns and textures |

In conclusion, textile fabric testing equipment plays a vital role in ensuring the quality, safety, and sustainability of textile products. By understanding the different types of testing equipment available and their applications, you can make informed decisions about which tools are necessary for your specific needs. With the increasing demand for eco-friendly and sustainable textiles, it is important to invest in high-quality testing equipment to support these efforts.

纺织品面料检测概述

随着纺织行业的快速发展,纺织品面料的质量和性能成为了消费者关注的焦点,为了确保纺织品面料的质量和安全,纺织品面料检测具有至关重要的作用,本篇将介绍一种先进的纺织品面料检测具,并通过英文案例说明其应用。

纺织品面料检测具介绍

纺织品面料检测具是一种集成了多种检测技术的设备,能够全面、准确地检测纺织品面料的质量和性能,该检测具主要包括以下几个方面的功能:

- 纤维分析:通过先进的纤维分析技术,检测面料中的纤维种类、含量、长度、直径等参数,确保面料纤维质量符合标准。

- 织物结构检测:利用先进的织物结构检测技术,检测面料的密度、织造工艺、纱线分布等参数,确保织物结构稳定、均匀。

- 物理性能测试:包括拉伸性能、弹性、耐磨性、抗皱性等,全面评估面料的物理性能。

英文案例说明

以某知名纺织品品牌为例,其采用先进的纺织品面料检测具进行面料检测,该品牌在生产过程中,对每一批次的纺织品面料都进行严格的检测,以确保产品质量和安全。

纤维分析

该品牌使用纺织品面料检测具进行纤维分析,检测结果显示,面料中的纤维种类丰富,含量稳定,符合国家标准,该检测具还能够对纤维的微观结构进行深入分析,为后续的织物结构和物理性能测试提供了有力支持。

织物结构检测

该品牌使用纺织品面料检测具进行织物结构检测,检测结果显示,面料的密度适中,织造工艺稳定,纱线分布均匀,该检测具还能够对织物的抗皱性进行测试,确保产品在运输和存储过程中不易变形。

纺织品面料检测具的应用

纺织品面料检测具的应用广泛,可以应用于以下几个方面:

- 质量控制:通过纺织品面料检测具对每一批次的纺织品面料进行全面检测,确保产品质量符合标准。

- 研发改进:根据纺织品面料检测具的测试结果,对产品进行研发改进,提高产品质量和性能。

- 环保要求:随着环保意识的提高,纺织品面料检测具在环保方面也发挥着重要作用,通过检测面料的环保性能,确保产品符合环保要求。

纺织品面料检测具是一种集成了多种检测技术的设备,能够全面、准确地检测纺织品面料的质量和性能,该设备的应用可以提高纺织品面料的品质和安全性,满足消费者对高质量产品的需求,随着科技的不断进步,纺织品面料检测具将会更加智能化、精准化,为纺织行业的发展提供更加有力的支持。

Articles related to the knowledge points of this article:

The Benefits of Choosing Quality Sleep Fabrics for a Better Nights Rest

A Comprehensive Guide to the Spectroscopic Database for Textiles

The Evolution and Impact of Hengxingli Textiles

The Evolution and Impact of Shaoxing Yifeng Textiles

Narishima Textiles:Crafting the Perfect Blend of Quality and Style