The Role of Textile Safety in Product Quality Control

In the realm of product quality control, textile safety plays a pivotal role in ensuring that products meet both functional and safety standards. This is particularly true in industries where the use of textiles is prevalent, such as apparel, footwear, and home furnishings. The importance of textile safety cannot be overstated, as it directly impacts the health and well-being of consumers.,To achieve this, manufacturers must adhere to strict regulations and guidelines set by regulatory bodies such as the International Organization for Standardization (ISO) and the United States Consumer Product Safety Commission (CPSC). These standards require manufacturers to ensure that their products are free from hazardous substances such as lead, phthalates, and flame retardants.,Furthermore, manufacturers must also incorporate innovative technologies into their production processes to enhance the safety of their products. For example, they may use advanced dyeing and finishing techniques that reduce the risk of skin irritation or allergic reactions. Additionally, they can implement eco-friendly materials that are not only safe for human health but also have a positive impact on the environment.,Ultimately, the success of any product quality control program depends on the commitment of manufacturers to prioritizing textile safety. By doing so, they can create products that not only meet consumer expectations but also contribute to a safer and healthier society.

Introduction: Textiles, as a vital component of our daily lives, come into direct contact with the skin and are exposed to various external factors. This makes them susceptible to hazards such as toxic substances, allergens, and microbes. Therefore, ensuring that these textiles are safe for human use is crucial. In this article, we will discuss the importance of textile safety, the testing methods used, and an example of successful textile safety testing from a real-life scenario.

Importance of Textile Safety: Textile safety refers to the assessment of the potential risks associated with textile products. It involves identifying and controlling hazards that may cause health problems or damage to the environment. Textile safety is essential for protecting consumers, workers, and the environment. It ensures that textile products meet regulatory standards and contribute to a safer and healthier living environment.

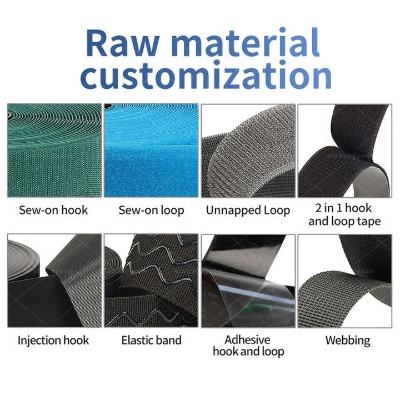

Testing Methods: There are various testing methods used to ensure textile safety, including:

-

Chemical Testing: This method involves analyzing the composition of textiles for any harmful chemicals, such as dyes, pesticides, and flame retardants. These chemicals can cause allergies, respiratory problems, and other health issues.

-

Microbial Testing: This method checks for the presence of harmful bacteria, viruses, and fungi on textiles. These microorganisms can cause infections, allergies, and other health problems.

-

Physical Testing: This method evaluates the quality of textiles by measuring their strength, durability, and resistance to wear and tear.

-

Environmental Testing: This method assesses the impact of textiles on the environment, including their ability to absorb water, degrade in landfills, and release harmful substances into the air or water.

Example: A recent case study involved a textile company that produced clothing for children's wear. The company was aware of the potential risks associated with some of its products and decided to conduct a comprehensive safety testing program. They used both chemical and microbial testing methods to identify any harmful substances present in the fabric. Additionally, they conducted physical and environmental testing to ensure that the product met all regulatory standards.

The results of the testing showed that the company's products passed all the tests and were safe for children's use. However, they also identified some areas where improvements could be made to further enhance the safety of the products. For example, they found that some of the fabrics had low levels of flame retardant, which could increase the risk of fire accidents. To address this issue, the company decided to increase the amount of flame retardant in the fabrics to meet new safety standards.

Conclusion: Textile safety is critical for ensuring that consumers and workers are protected from hazards associated with textile products. By conducting thorough testing methods, companies can identify and eliminate potential risks before they become a problem. In addition, companies should continuously monitor and update their safety protocols to stay ahead of emerging hazards and regulations. As shown in the example above, successful textile safety testing can lead to improved products that meet consumer needs while reducing environmental impacts.

纺织品安全物质检验的重要性

纺织品安全物质检验在保障消费者健康和安全方面具有重要意义,通过检验纺织品中可能存在的有害物质,可以确保纺织品符合相关安全标准和法规要求,从而保障人们的穿着安全和健康。

纺织品安全物质检验的流程与标准

- 样品采集与处理:收集待检测的纺织品样品,并进行必要的处理,如清洗、剪裁等。

- 化学分析:使用各种化学分析方法对纺织品进行检测,包括但不限于重金属含量、有害物质含量等。

- 安全性评估:根据检测结果,对纺织品的安全性进行评估,确定是否符合相关安全标准和法规要求。

- 检验标准:根据不同的纺织品类型和用途,制定相应的检验标准,确保检验结果的准确性和可靠性。

纺织品安全物质检验案例分析

某品牌纺织品安全检验

某品牌近期对其纺织品进行了安全物质检验,主要检测纺织品中是否存在有害物质,经过检测,该品牌纺织品符合相关安全标准和法规要求,消费者可以放心使用。

纺织品重金属含量检测

某地区的一家纺织厂生产的纺织品进行了重金属含量检测,检测结果显示,该厂生产的纺织品重金属含量符合国家标准,消费者可以放心购买。

纺织品安全物质检验方法与技巧

- 化学分析法:使用各种化学分析方法对纺织品进行检测,包括但不限于重量分析、比表面积分析、元素分析等,在检测过程中,需要注意样品处理、试剂选择和操作规范等。

- 仪器分析法:使用各种仪器分析法对纺织品进行检测,如原子吸收光谱法、气相色谱法等,这些仪器分析法具有较高的准确性和可靠性,适用于大规模的纺织品检测。

纺织品安全物质检验注意事项

- 样品采集与处理要规范:确保样品采集和处理符合相关标准和规范要求,避免样品受到污染或损坏。

- 检测结果要准确可靠:在检测过程中,需要注意试剂选择和操作规范等,确保检测结果的准确性和可靠性,需要定期对检测设备进行校准和维护。

- 安全意识要提高:在进行纺织品安全物质检验时,需要提高消费者的安全意识,让消费者了解纺织品中可能存在的有害物质及其危害性。

纺织品安全物质检验是保障消费者健康和安全的重要手段,通过科学、规范的检验流程和标准,可以确保纺织品符合相关安全标准和法规要求,需要提高消费者的安全意识,让消费者了解纺织品中可能存在的有害物质及其危害性,在实际操作中,需要注意样品采集与处理规范、检测结果准确可靠等方面的问题。

Articles related to the knowledge points of this article:

A Comprehensive Guide to Visiting Inventory of Textile Supplies in Yancheng