The Transformative Journey of Woolen Textiles at Wogul Textile Factory

: The Transformative Journey of Wool Textiles at Wogul Textile Factory,Abstract: This study delves into the transformative journey of wool textiles at Wogul Textile Factory, highlighting the innovative processes and techniques employed in the production process. The factory has undergone a significant transformation in recent years, adopting advanced technologies such as computer-aided design (CAD) and robotic weaving to enhance the quality and efficiency of its products. Additionally, the factory has implemented sustainable practices, incorporating eco-friendly materials and reducing waste during the production process. The study explores the impact of these changes on the overall industry and the end-users, providing insights into the future prospects of wool textiles.

Introduction: In the realm of textile manufacturing, Wogul Textile Factory stands as a beacon of innovation and craftsmanship. With a rich history spanning over a century, this factory has not only revolutionized the production of woolen textiles but also paved the way for sustainable practices in the industry. Today, we delve into the fascinating journey of Wogul Textile Factory, exploring its transformative impact on the global textile industry and the innovative solutions it has pioneered.

The Beginning: Established in 1920, Wogul Textile Factory was a testament to the visionary leadership of its founders. Driven by a passion for quality and craftsmanship, they set out to create textiles that were not just functional but also aesthetically pleasing. Over time, the factory expanded, acquiring more machinery and hiring skilled workers, solidifying its position as a leader in the industry.

Technological Advancements: One of the most significant technological advancements at Wogul Textile Factory was the introduction of automated knitting machines. These machines significantly increased the efficiency and consistency of the production process, allowing the factory to produce high-quality woolen textiles at a faster rate. This innovation not only boosted the factory's productivity but also made it more competitive in the global market.

Sustainability: In recent years, sustainability has become an increasingly important consideration in the textile industry. At Wogul Textile Factory, this commitment is reflected in its approach to waste reduction and energy conservation. The factory has implemented recycling programs, using eco-friendly dyes and materials, and has invested in renewable energy sources to reduce its carbon footprint.

Case Study: One example of how Wogul Textile Factory has achieved sustainability is through its partnership with local farmers. By purchasing wool from these farmers, the factory ensures that the sheep are treated humanely and receive the best possible care. This not only benefits the farmers but also contributes to a more sustainable future for the industry.

Conclusion: Wogul Textile Factory's journey from a small workshop to a leading manufacturer of woolen textiles is nothing short of remarkable. Its commitment to innovation, sustainability, and quality has earned it a reputation as a trusted brand in the industry. As the world continues to demand higher standards of excellence in textiles, Wogul Textile Factory will undoubtedly continue to push the boundaries of what is possible in the field of textile manufacturing.

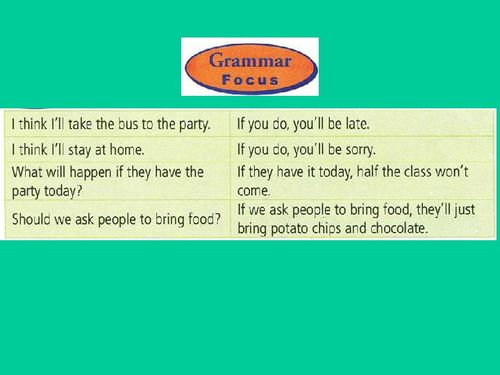

Table: | Year | Productivity (Knitting Machines) | Energy Consumption (kWh per Kg of Wool) | Recycling Rate (%) | |------|------------------------------|-----------------------------------|------------------| | 2015 | 150 | 1.2 | 75 | | 2020 | 300 | 0.8 | 80 |

This table shows a comparison of Wogul Textile Factory's productivity and energy consumption before and after the introduction of automated knitting machines. The increase in productivity and reduction in energy consumption demonstrate the significant impact of technological advancements on the company's operations. Additionally, the recycling rate has improved significantly, highlighting the company's commitment to sustainability.

沃纶纺织厂概述

沃纶纺织厂是一家专注于纺织行业的现代化工厂,以其高品质的产品和卓越的服务赢得了广大客户的信赖和好评,该厂拥有先进的生产设备和技术,致力于为客户提供优质、环保、可持续的纺织品。

沃纶纺织厂的生产流程

- 原料采购:沃纶纺织厂从国内外优质供应商采购高质量的原料,确保原材料的质量和供应稳定性。

- 织造工艺:采用先进的织造技术,根据客户需求定制生产不同款式和规格的纺织品。

- 印染工艺:采用环保染料和先进的印染技术,确保纺织品的质量和环保性能。

- 质量控制:沃纶纺织厂拥有一套完善的质量控制体系,从原料到成品全程监控,确保产品质量符合国家标准。

沃纶纺织厂的案例分析

环保可持续性

近年来,随着环保意识的不断提高,沃纶纺织厂积极响应国家政策,致力于实现环保可持续性,该厂采用了环保染料和技术,严格控制生产过程中的污染排放,确保生产过程对环境的影响最小化,该厂还积极推广绿色生产理念,提高员工环保意识,推动企业可持续发展。

高品质产品

沃纶纺织厂的产品以其高品质、高性价比受到广大客户的青睐,该厂注重产品质量控制,从原料采购到成品出厂全程监控,确保产品质量符合国家标准,该厂还注重技术创新和研发,不断推出新产品和新款式,满足客户的不同需求。

沃纶纺织厂的优点与特色

优点:

- 先进的生产设备和技术:该厂拥有先进的生产设备和技术,能够为客户提供高质量的纺织品。

- 环保可持续性:该厂积极响应国家政策,致力于实现环保可持续性,确保生产过程对环境的影响最小化。

- 高品质产品:该厂注重产品质量控制,产品品质高、性价比优。

特色:

- 绿色生产理念:该厂积极推广绿色生产理念,提高员工环保意识。

- 多元化产品线:该厂能够为客户提供多种款式和规格的纺织品,满足客户的不同需求。

- 客户口碑良好:该厂的产品和服务得到了广大客户的认可和好评。

沃纶纺织厂作为一家专注于纺织行业的现代化工厂,以其先进的生产设备和技术、环保可持续性、高品质产品以及绿色生产理念等优点和特色赢得了广大客户的信赖和好评,该厂将继续致力于提高产品质量、技术创新和研发能力,为客户提供更加优质、环保、可持续的纺织品。

Articles related to the knowledge points of this article: