The Fabric of Innovation:An Overview of Polyester Production in Textile Mills

"The Fabric of Innovation: An Overview of Polyester Production in Textile Mills",Polyester, a versatile and widely used synthetic fiber, is an essential component in the production of textiles. In this article, we will explore the fabric of innovation in polyester production in textile mills.,The process of polyester production involves several stages, from raw material extraction to final product manufacturing. The first step is the extraction of petroleum byproducts, such as butane or propane, which are then converted into dimethyl terephthalate (DMPT) through a chemical reaction. DMPT is then processed further to form polyester, which is then spun into thread and woven into fabric.,Innovation in polyester production has been driven by advancements in technology, including the use of more efficient and sustainable processes. For example, the development of new polymerization techniques has allowed for higher yields and reduced waste. Additionally, advances in automation and robotics have made it possible to produce polyester at a faster rate and with greater consistency.,Despite these advancements, there are still challenges in the production of polyester, such as the need for energy-intensive processes and the potential for environmental impact. However, as demand for sustainable and eco-friendly materials continues to rise, it is likely that innovation in polyester production will continue to drive growth in this industry.

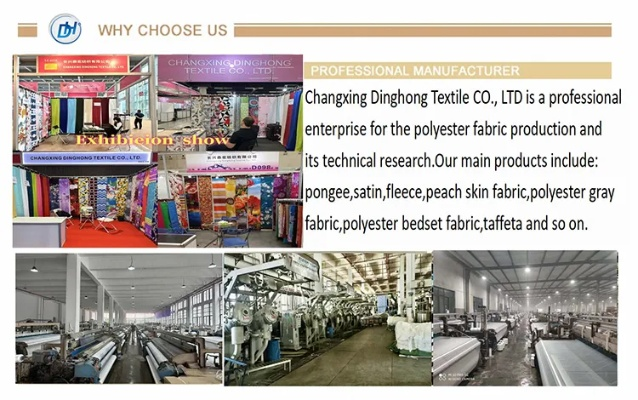

Introduction: In the realm of textile production, polyester is a ubiquitous material, found in everything from everyday wear to high-end fashion. Its durability and resistance to heat and moisture make it an essential component of the fabric we all rely on. But what happens behind the scenes in the world of polyester manufacturing? How does this versatile polymer get made into the threads that make up our clothing, furnishings, and other textile products? Let's dive into the world of polyester production in textile mills, where technology meets creativity to create the fabric of tomorrow.

Textile Mill Overview: A textile mill is a facility designed to produce a wide range of textile products using various processes. These include spinning, weaving, dying, and finishing. In the context of polyester production, spinning and weaving are crucial steps that transform raw materials into finished fabrics.

Spinning Process: The first step in polyester production is spinning, which involves converting long fibers into short fibers suitable for weaving. Spinning takes place in a large spinning frame, where molten polyester is extruded through a spinneret onto a rotating cylinder called a "drawing cup." The fibers then cool and solidify, forming the thread that will be used to create textiles.

Weaving Process: Once the thread has been spun, it enters the weaving process, where it is woven into fabric. This is done using a loom or a machine with multiple strands, depending on the desired pattern and thickness of the fabric. The weavers manipulate the threads according to a pattern chart, creating intricate patterns and designs that add visual interest to textiles.

Dyeing Process: After weaving, the fabric undergoes dyeing to enhance its color and texture. Dyes are added to the fabric using either a dry or wet method, depending on the desired finish. The fabric is then rinsed and dried, leaving behind a vibrant and lasting color that can last for years.

Finishing Process: Finally, the fabric is ready for any additional treatments such as printing, embroidery, or coating. These finishes can enhance the aesthetic appeal of the fabric or provide functional benefits like water repellency or flame resistance.

Polyester Production Challenges: Despite its widespread use, polyester production faces several challenges that must be addressed to ensure sustainability and quality. One major challenge is waste management. While polyester is highly durable, it also tends to decompose slowly, leading to environmental concerns. Textile mills must find ways to minimize waste by recycling and reusing materials efficiently.

Another challenge is energy efficiency. Polyester production requires significant amounts of energy, both in the form of electricity and natural gas. Textile mills must invest in renewable energy sources and adopt more efficient technologies to reduce their carbon footprint.

Technology Advancements: Advances in technology have played a crucial role in improving polyester production. For example, the use of bio-based polyester derived from plant-based materials has become increasingly popular. This not only reduces the environmental impact but also offers new opportunities for innovation in the textile industry.

Machinery advancements have also transformed the way polyester is produced. Advanced spinning machines can produce higher-quality thread with greater precision, while automated weaving systems can handle larger volumes of fabric more quickly and efficiently.

Case Study: One textile mill that has successfully integrated these technological advancements is the Bangladesh-based Tharif Textiles Ltd. Located in the heart of Bangladesh's garment industry, Tharif Textiles has been at the forefront of sustainable polyester production for over a decade. By using state-of-the-art machinery and adopting eco-friendly practices, the company has reduced its carbon footprint significantly and increased its competitiveness in the global market.

Conclusion: Polyester production is a complex and challenging process that requires constant innovation and adaptation to meet changing consumer demands and environmental standards. As textile mills continue to push boundaries in polyester production, they play a critical role in shaping the future of fashion and sustainability. By embracing technology and adopting sustainable practices, textile mills can not only produce high-quality polyester fabrics but also contribute to a greener, more sustainable future.

纺织厂聚酯设备概述

在当今的纺织行业中,聚酯设备扮演着至关重要的角色,这些设备不仅提高了生产效率,还推动了纺织行业的现代化和智能化,本文将重点介绍纺织厂聚酯设备的类型、特点及其在生产过程中的作用。

聚酯设备类型及特点

设备类型:纺织厂常见的聚酯设备主要包括挤出机、纺丝机、干燥机等,挤出机主要用于生产高强度、高模量的聚酯纤维,而纺丝机则是将聚合物原料通过特定的工艺转化为纤维的关键设备。

(1)挤出机:挤出机是一种高温高压的设备,主要用于生产各种聚酯纤维,其特点是能够精确控制纤维的形状和尺寸,同时具有高产量和高效率的特点。

(2)纺丝机:纺丝机是聚酯纤维生产过程中的核心设备,其工艺包括熔融、牵引、拉伸等步骤,先进的纺丝机能够生产出高质量、高强度、高模量的聚酯纤维,满足不同领域的需求。

特点:

(1)高效节能:聚酯设备采用了先进的节能技术,能够高效地利用能源,降低生产成本。

(2)环保友好:聚酯设备在生产过程中注重环保,采用了环保材料和工艺,减少了废物的产生和对环境的污染。

(3)自动化程度高:现代聚酯设备通常具备较高的自动化程度,能够自动控制生产过程中的各种参数,提高生产效率。

案例说明

以某纺织厂为例,该厂采用了先进的聚酯设备,实现了高效、环保、智能化的生产。

-

设备选择:该纺织厂选择了先进的挤出机和纺丝机,能够满足不同类型和规格的聚酯纤维生产需求。

-

生产过程:在生产过程中,该厂采用了自动化控制系统,能够自动控制生产过程中的各种参数,提高了生产效率,该厂还采用了节能技术,降低了生产成本,该厂注重环保,采用了环保材料和工艺,减少了废物的产生和对环境的污染。

英文案例分析

在纺织行业中,一些先进的聚酯设备采用了先进的工艺和技术,实现了高效、环保、智能化的生产,以下是一个英文案例说明:

英文案例:A Textile Factory Utilizes Advanced Polystone Equipment for High-Efficiency, Environmentally Friendly, and Intelligent Production

在这个案例中,一家纺织厂采用了先进的聚酯设备,实现了高效、环保、智能化的生产,该厂选择了先进的挤出机和纺丝机,采用了自动化控制系统和节能技术,该厂注重环保,采用了环保材料和工艺,减少了废物的产生和对环境的污染,以下是该案例的一些关键信息:

-

设备类型:挤出机和纺丝机是该纺织厂的主要聚酯设备,这些设备采用了先进的工艺和技术,能够精确控制纤维的形状和尺寸,同时具有高产量和高效率的特点。

-

生产过程:在生产过程中,该厂采用了先进的自动化控制系统和节能技术,自动化控制系统能够自动控制生产过程中的各种参数,提高了生产效率,该厂注重环保,减少了废物的产生和对环境的污染,该厂还采用了环保材料和工艺,确保了生产的可持续性和环境保护。

-

技术应用:该纺织厂采用了多项先进的技术应用,如智能传感器、大数据分析等,这些技术的应用提高了生产过程的智能化水平,使得生产更加高效、精准和环保。

纺织厂聚酯设备的现代化和智能化是推动纺织行业发展的重要因素,本文介绍了纺织厂聚酯设备的类型、特点及其在生产过程中的作用,通过一个英文案例分析,进一步说明了先进聚酯设备的优势和应用,随着技术的不断进步和产业升级的需求,纺织行业将继续追求高效、环保、智能化的生产方式。

Articles related to the knowledge points of this article:

The Transformative Journey of the Qi County Textile Mill

The Role of Textile Factory Womens Teachers

A Night of Fire and Fury at the Shaoxing Textile Factory