The Role of Leather and Textile Testing in Quality Assurance

: The Role of Leather and Textile Testing in Quality Assurance,In the realm of quality assurance, leather and textile testing play a crucial role. These materials are integral to various industries, from fashion to construction, and their performance is critical to ensuring customer satisfaction and product reliability.,Leather testing is essential for assessing the durability and quality of leather products. This includes evaluating the strength, flexibility, and resistance to wear and tear, as well as determining the level of tannin content and other impurities that can affect the material's appearance and feel. By conducting these tests, manufacturers can ensure that their leather products meet industry standards and meet consumer expectations.,Textile testing is equally important in ensuring the quality and safety of textile products. This includes evaluating the fabric's strength, durability, and resistance to wear and tear, as well as assessing the level of dyes and pigments used and their impact on colorfastness and washability. By conducting these tests, manufacturers can ensure that their textile products meet safety and environmental standards and meet consumer expectations.,In conclusion, leather and textile testing are critical components of quality assurance in the manufacturing process. By carefully evaluating the performance of these materials, manufacturers can ensure that their products meet industry standards and consumer expectations, ultimately leading to increased customer satisfaction and market success.

Introduction: In the world of fashion, quality is king. From the intricate designs on a dress to the durability of a pair of shoes, every element must meet high standards of excellence. One crucial aspect of ensuring these products' quality is through thorough testing. This includes not only physical inspections but also specialized tests that ensure the materials used are of the highest quality. In this article, we will delve into the importance of leather and textile testing and provide insights into how they contribute to product quality assurance.

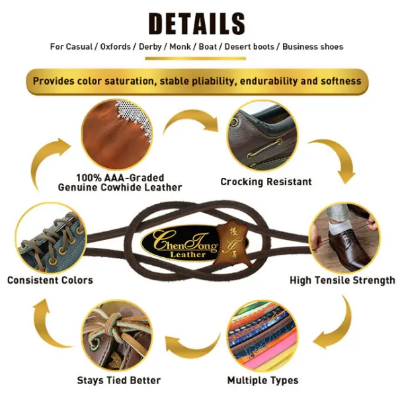

Leather Testing: Leather is one of the most sought-after materials for making footwear, bags, and other accessories due to its unique properties such as softness, flexibility, and resistance to water. However, it is also prone to wear and tear, which can lead to degradation over time. Therefore, leather testing is essential to determine its condition and ensure that it meets the desired standards.

The following table provides a summary of some common leather testing methods used in the industry: | Test Method | Purpose | | --- | --- | | Color Testing | Checks for discoloration or fading | | Grain Testing | Determines the texture and grain pattern of the leather | | Water Absorption Testing | Assesses the ability of the leather to absorb moisture | | Tear Resistance Testing | Measures the strength of the leather against tearing | | Odor Testing | Detects any pungent odors that may indicate spoilage or damage | | pH Testing | Analyzes the acidity or alkalinity of the leather, affecting its color and texture |

Leather testing not only ensures that the product meets consumer expectations but also helps manufacturers maintain their brand reputation by providing reliable information about the quality of their products. For example, if a shoe manufacturer discovers that a particular type of leather has poor tear resistance, they may need to invest in new technology or processes to improve this aspect of the product.

Textile Testing: Textile testing is equally critical for ensuring the quality of clothing, bedding, and other textile products. Unlike leather, textiles are made from various materials such as cotton, polyester, and silk, each with its own set of properties and requirements for quality assurance.

Some common textile testing methods include:

| Test Method | Purpose |

|---|---|

| Shrinkage Testing | Measures the degree to which a textile shrinks when washed |

| Flammability Testing | Assesses the potential risk of fire during use |

| Stress Testing | Determines the resilience of the textile under different loads |

| Cryptochrome Testing | Measures the amount of light absorbed by the textile |

| Moisture Permeability Testing | Assesses how quickly the textile can absorb or release moisture |

| Bacteria Count Testing | Checks for the presence of harmful bacteria on the textile surface |

Textile testing not only helps manufacturers identify defects in their products but also helps them develop new materials or processes that can enhance their products' performance and longevity. For example, if a manufacturer discovers that a specific type of cotton fabric has poor flammability, they may need to invest in more flame-resistant coatings or dyes to improve this aspect of the product.

Case Study: Let's take a closer look at a real-life example of how leather and textile testing play a crucial role in product quality assurance. Imagine a luxury handbag brand that specializes in handmade leather goods. To ensure that their products meet the highest standards of quality, they conduct regular leather testing on all their products before they hit the market.

One day, after a series of successful sales, the brand receives a complaint from a customer who received a damaged bag. Upon investigation, the brand realizes that the problem was caused by an uneven cut in the leather, resulting in a gap between the seams. The brand immediately retests the affected area using their standard leather testing protocol. They find that the cut did not affect the overall quality of the leather but did cause a slight increase in water absorption.

To address this issue, the brand decides to replace the affected section of the bag with a new piece of leather that has been specifically designed to have reduced water absorption. This change not only resolves the customer complaint but also demonstrates the brand's commitment to quality control and customer satisfaction.

Conclusion: In conclusion, both leather and textile testing are essential components of product quality assurance. By regularly conducting these tests, manufacturers can identify and address any potential issues before they become problems for consumers. By doing so, they not only build trust with their customers but also help create a positive reputation for their brand. As such, investing in quality testing is not just a cost-effective move but a strategic decision that can pay dividends in the long run.

在日常纺织品检测中,皮革检测是一项至关重要的环节,它不仅关系到产品的质量,还关系到消费者的权益和安全,本文将围绕皮革检测纺织品检测的主题,通过英文案例说明和表格补充说明的方式,为大家详细解读这一过程。

皮革检测的重要性

皮革检测是纺织品质量控制的必要环节,通过皮革检测,可以确保纺织品符合相关标准和法规要求,保障消费者的使用安全和权益,皮革检测也是企业产品质量保证的重要手段。

纺织品检测的主要内容

纺织品检测主要包括以下几个方面:

- 外观检查:检查纺织品外观是否整洁、无瑕疵。

- 纤维含量检测:检测纺织品的纤维含量是否符合标准。

- 化学成分分析:分析纺织品的化学成分,了解其成分组成和含量。

- 微生物检测:检测纺织品是否存在微生物污染。

- 环保性能检测:检测纺织品是否符合环保要求。

英文案例说明

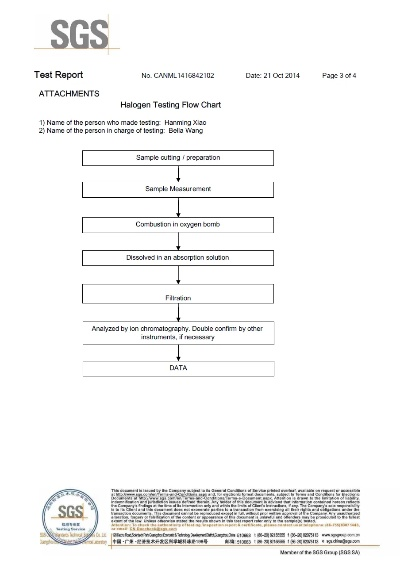

以某皮革制品公司为例,其纺织品检测流程如下:

- 外观检查:检查皮革制品的外观是否整洁、无瑕疵。

- 纤维含量检测:使用专业仪器对皮革制品的纤维含量进行检测,确保符合国家标准。

- 化学成分分析:对皮革制品进行化学成分分析,了解其成分组成和含量,该过程需要使用专业的化学分析仪器,确保分析结果的准确性。

- 微生物检测:对皮革制品进行微生物检测,确保不存在微生物污染,该过程需要使用专业的微生物检测设备,确保检测结果的可靠性。

- 环保性能检测:对皮革制品进行环保性能检测,确保符合相关环保标准,该过程需要参考相关的环保标准,确保皮革制品符合环保要求。

表格补充说明

以下是皮革检测纺织品检测的相关表格补充说明:

| 项目名称 | 检测方法 | 具体要求 | 示例数据 |

|---|---|---|---|

| 外观检查 | 观察法 | 无瑕疵、整洁 | 该皮革制品外观整洁,无瑕疵 |

| 纤维含量检测 | 仪器分析法 | 符合国家标准 | 该皮革制品纤维含量符合国家标准要求 |

| 化学成分分析 | 专业仪器分析法 | 准确无误 | 该皮革制品化学成分分析结果准确无误 |

| 微生物检测 | 专业设备法 | 无微生物污染 | 该皮革制品微生物检测结果为阴性,无微生物污染 |

| 环保性能检测 | 相关标准参考 | 符合环保要求 | 该皮革制品环保性能检测结果符合相关环保标准要求 |

皮革检测纺织品检测是确保纺织品质量的重要环节,通过专业的皮革检测设备和严格的检测流程,可以确保纺织品符合相关标准和法规要求,保障消费者的使用安全和权益,企业也应该加强自身的质量控制体系,提高产品质量和竞争力。

Articles related to the knowledge points of this article:

The Testing of Textiles for Nucleic Acid

Traditional Chinese Home Textiles:A Journey Through the中式古典家用纺织品案例分析