The Fabric of Innovation:An Insight into Textile Industry Knowledge

The Fabric of Innovation: An Insight into Textile Industry Knowledge,Innovation is the driving force behind the growth and development of the textile industry. The textile industry is a complex and dynamic sector that requires constant innovation to stay competitive in the global market. This paper aims to explore the knowledge base of the textile industry, including its history, current state, and future prospects.,The textile industry has a long and rich history, dating back to ancient civilizations such as Egypt, Greece, and Rome. Over time, it evolved into various forms, including weaving, knitting, embroidery, and printing. Today, the textile industry encompasses a wide range of products, including clothing, household goods, and industrial materials.,The current state of the textile industry is characterized by high levels of automation and technological advancements. Machine learning, artificial intelligence, and robotics are increasingly being used in the industry to improve efficiency, reduce costs, and enhance product quality. Additionally, sustainable practices are becoming increasingly important as consumers demand more environmentally friendly products.,Looking forward, the textile industry faces several challenges and opportunities. On the one hand, there is a growing demand for eco-friendly and sustainable materials, which will drive innovation in the industry. On the other hand, advances in technology and automation will require new skills and training programs to ensure continued success.,In conclusion, the textile industry is at a critical juncture where innovation is essential to its continued growth and success. By understanding the knowledge base of the industry, stakeholders can better position themselves to capitalize on emerging trends and opportunities.

Introduction: The textile industry, with its rich history and diverse range of products, is one of the most significant sectors in the global economy. From the humble loom to the cutting-edge technology, the textile industry has come a long way, embracing innovation and adapting to the changing demands of modern society. In this presentation, we will explore the key knowledge points that underpin the textile industry, from raw materials to finished products, and how these elements interconnect to create a vibrant and dynamic industry.

I. Raw Materials: The Foundation of Textile Production Textile production begins with the selection of high-quality raw materials, which are crucial for the quality and durability of the end product. Here's a table summarizing some of the most commonly used raw materials:

| Raw Material | Sources | Importance |

|---|---|---|

| Cotton | Globally sourced from various regions | High in breathability and softness |

| Polyester | Grown using renewable resources like corn | Versatile and durable |

| Spandex | Produced from natural rubber latex | Elasticity and stretchiness |

| Nylon | Manufactured from petroleum byproducts | Durable and strong |

| Wool | Grown on sheep or goats | Soft and warm |

II. Processing Techniques: Crafting Quality Products Once raw materials are obtained, they undergo a series of processing techniques to transform them into fabrics suitable for clothing, furnishings, and other applications. These techniques include:

- Weaving: A process where warp threads are woven onto a backing fabric to form a continuous length of cloth.

- Knitting: A method of producing textiles by interlocking loops of yarn.

- Embroidery: A decorative technique that involves stitching small designs onto fabric.

- Printing: A method of applying patterns onto fabric using inks or dyes.

- Dyeing: A process of treating fabric to change its color.

- Shrinkage: A process that reduces the size of fabric after washing.

- Stitching: A method of joining two or more pieces of fabric together.

III. End-Use Products: The Various Facets of Textiles Textiles come in a wide variety of forms, each tailored to meet specific needs and preferences. Some popular end-use products include:

- Clothing: From casual wear to formal attire, textiles are the foundation of fashion.

- Home furnishings: Bedding, curtains, upholstery, and rugs all rely on textiles for their aesthetic appeal and practicality.

- Footwear: Shoes, boots, and accessories are made from a wide range of textiles, including leather, suede, and synthetic fibers.

- Electronics: Textiles are also used in electronics, such as insulating foams and thermal blankets.

- Medical devices: Textiles are often used in medical equipment, such as bandages, surgical gowns, and hospital gowns.

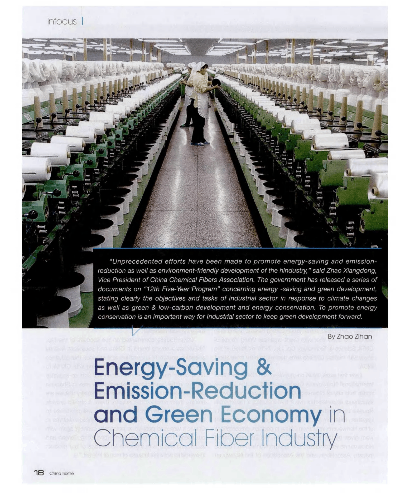

IV. Sustainability and Ethical Practices: The Future of Textiles As the textile industry continues to grow, concerns about sustainability and ethical practices have become increasingly important. Here are some ways in which textile companies are addressing these issues:

- Renewable Materials: Many manufacturers are switching to sustainable sources of raw materials, such as organic cotton or recycled polyester.

- Energy Efficiency: Advances in technology are enabling textile companies to use less energy and water in their production processes.

- Fair Trade: Companies are adopting fair trade practices to ensure that workers are paid fairly and work conditions are safe and healthy.

- Environmental Impact: Textile companies are investing in research and development to reduce their environmental footprint by using eco-friendly dyes and solvents.

- Education and Awareness: Many companies are working to educate consumers about the importance of sustainable textiles and the impact of their choices on the planet.

Conclusion: The textile industry is a complex and multifaceted sector that relies on a wide range of raw materials, processing techniques, and end-use products. As we continue to grapple with issues such as sustainability and ethical practices, it's clear that innovation and adaptation are key to ensuring the long-term success of this vital industry. By staying informed about the latest advancements in the textile world, you can gain a deeper understanding of the challenges and opportunities facing this fascinating industry.

纺织行业背景

纺织行业是全球重要的工业领域之一,涵盖了从纤维原料采集、纺纱、织造到染整等多个环节,随着科技的进步和消费者需求的多样化,纺织行业正经历着快速的发展和变革。

纺织厂的主要工作内容

- 原料采集与处理:从各种天然或合成纤维原料中提取纤维,并进行必要的预处理,如粉碎、混合等。

- 纺纱:使用先进的纺纱技术将纤维制成纱线。

- 织造:将纱线织成各种面料和服装。

- 染整:对织物进行染色、整理等加工,使其具有特定的外观和性能。

纺织厂的关键技术

- 纺纱技术:包括高速纺纱、无纺纱等先进技术,提高了生产效率和产品质量。

- 织造工艺:包括平纹、斜纹、提花等多种织造方式,满足了不同面料的制作需求。

- 染整工艺:包括染色、印花、防水处理等,提高了织物的耐久性和功能性。

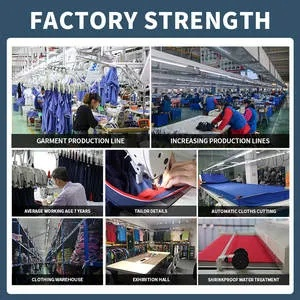

纺织厂的管理与运营

- 生产管理:采用先进的生产管理系统,实现生产过程的自动化和智能化。

- 质量检测:建立严格的质量检测体系,确保产品质量符合标准。

- 环境保护:注重环境保护,采用环保工艺和技术,减少污染排放。

- 员工培训:定期进行员工培训,提高员工技能水平和综合素质。

案例分析:纺织厂的实践应用

某知名纺织厂的生产流程与技术创新

该纺织厂采用了先进的纺纱技术,实现了高效的生产和高质量的产品,该厂还注重技术创新,不断研发新的产品和技术,满足市场需求,该厂的实践应用表明,纺织厂在生产过程中需要注重环保和节能,采用环保工艺和技术,提高生产效率和产品质量,还需要注重员工培训和管理,提高员工技能水平和综合素质。

纺织厂在行业中的竞争优势与市场前景

该纺织厂在行业中具有较高的知名度和竞争力,其产品深受消费者喜爱,随着消费者需求的多样化,该纺织厂将继续加强技术创新和产品研发,提高产品质量和竞争力,该厂还注重市场拓展,拓展新的市场领域和客户群体,纺织行业将继续保持快速发展和变革的趋势,纺织厂也将面临更多的机遇和挑战。

纺织厂未来发展趋势与展望

随着科技的进步和消费者需求的多样化,纺织行业将继续保持快速发展和变革的趋势,纺织厂需要注重技术创新和产品研发,提高产品质量和竞争力,还需要注重环境保护和可持续发展,推动绿色制造和低碳生产,纺织厂还需要加强员工培训和管理,提高员工技能水平和综合素质,未来纺织行业还将面临更多的机遇和挑战,但同时也将带来更多的发展机会和发展空间。

Articles related to the knowledge points of this article:

A Brief Guide to the Fabrication Process at Shang Li Textile Factory

The Story of the Spinning Silk in Prosperous Pang Shan Linhong Textile Factory