The Art of Monitoring and Managing Textile Production

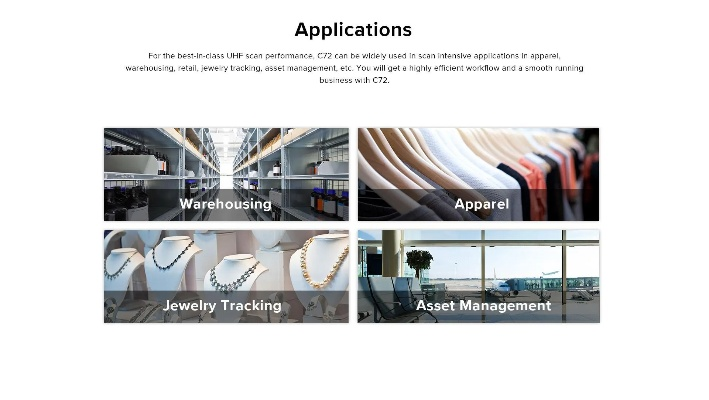

: Monitoring and Managing Textile Production,The art of monitoring and managing textile production involves a complex interplay between various factors such as quality control, efficiency, and sustainability. This process involves the continuous monitoring of raw materials, processes, and final products to ensure that they meet specific standards and requirements. It also involves the effective management of resources, including labor, machinery, and energy, to optimize production while minimizing waste and environmental impact.,One key aspect of this art is the use of advanced technologies such as computer-aided design (CAD) systems, robotics, and artificial intelligence (AI) to automate and optimize production processes. These technologies can help textile manufacturers improve their productivity, reduce costs, and increase product quality.,Another important aspect of monitoring and managing textile production is the integration of sustainability principles into the manufacturing process. This includes using eco-friendly materials, reducing energy consumption, and minimizing waste during the production process. Sustainable practices not only contribute to environmental protection but also enhance the brand image and market competitiveness of textile manufacturers.,Overall, the art of monitoring and managing textile production requires a multifaceted approach that combines technological innovation, resource optimization, and sustainability principles to achieve optimal results.

Introduction: In the ever-evolving textile industry, maintaining a comprehensive record of production activities is crucial for ensuring efficiency, accuracy, and compliance with regulations. This guide aims to provide an overview of how to create and maintain a detailed textile production logbook, using a combination of tables and case studies to illustrate best practices.

Step 1: Establishing the Production Logbook The first step in creating a production logbook is to decide on its purpose and scope. A typical textile production logbook should include information about the materials used, the process steps taken, the equipment used, the quality control measures implemented, and any issues encountered during the production cycle.

Table 1: Production Logbook Structure | Component | Details | Purpose | |------------|------------|--------------| | Date | Start date and time | Record start of production | | Machine Name | Used machine/equipment | Record the machine used | | Materials | Type, quantity, source | Record the materials used | | Process Steps | Detailed description of each step | Record the steps taken | | Quality Control | Checklists, inspection results | Record quality checks conducted | | Issues | Identified problems and solutions | Record any issues encountered | | Operator | Who performed each task | Record who completed each task | | Finished Product | Description of finished product | Record the final product |

Step 2: Compiling the Logbook Once the structure has been established, it's time to begin compiling the production logbook. This involves recording all relevant information accurately and consistently over the course of the production run. It's important to ensure that every detail is accounted for to avoid discrepancies later on.

Case Study: ABC Textiles ABC Textiles was experiencing a decline in productivity due to frequent quality control violations. To address this issue, management decided to implement a comprehensive production logbook system. They created a standardized template for the logbook and trained staff on its proper use. By tracking each step of the production process from start to finish, they were able to identify specific areas of improvement and implement changes accordingly. As a result, not only did their quality control improve but also their overall production efficiency.

Step 3: Maintaining the Logbook Once the production logbook is compiled, it must be regularly updated and maintained. This ensures that any changes made during the production cycle are recorded accurately. Additionally, regular reviews can help identify trends or patterns that may require further investigation.

Conclusion: Creating and maintaining a comprehensive textile production logbook is essential for ensuring efficient and accurate operations within the textile industry. By following the steps outlined above and incorporating best practices such as table structures and case studies, businesses can streamline their processes, reduce errors, and enhance their overall performance. With consistent attention to detail and ongoing improvements, the textile industry can continue to thrive and meet the demands of modern markets.

大家好,今天我们将探讨纺织厂生产台账的重要性及其在实际操作中的运用,通过这份台账,我们可以更好地掌握生产进度、成本核算以及质量控制等关键信息,从而优化生产流程、提高生产效率,下面我们将从表格和案例说明两个方面详细介绍纺织厂生产台账的相关内容。 概述

台账表格设计

台账表格应包含以下关键信息:

(1)产品名称及规格 (2)原材料采购情况 (3)生产过程记录 (4)半成品入库与出库情况 (5)成品入库与销售情况 (6)设备维护与检修记录 (7)成本核算与分析

案例分析

以某纺织厂为例,其生产台账的详细内容如下:

(1)原材料采购情况:记录了原材料的种类、数量、供应商等信息。 (2)生产过程记录:详细记录了从原料到成品的整个生产过程,包括工艺流程、操作步骤等。 (3)半成品入库与出库情况:记录了半成品的数量、状态等信息。 (4)成本核算与分析:通过成本核算表,对生产成本、销售成本等进行详细分析,为成本控制和优化提供依据。

台账操作要点

定期更新台账数据

纺织厂应定期更新台账数据,确保信息的准确性,应根据生产实际情况及时调整台账内容。

加强数据安全管理

在台账数据管理中,应加强数据安全管理,防止数据泄露和丢失,应建立完善的数据备份和恢复机制,确保数据安全可靠。

强化团队协作与沟通

纺织厂应加强团队协作与沟通,确保各部门之间的信息共享和协同工作,应定期组织员工培训,提高员工对台账管理的认识和技能水平。

台账在实际操作中的运用案例说明

某纺织厂的生产管理优化实践

某纺织厂在实施生产台账管理后,实现了生产过程的透明化管理,提高了生产效率和质量,具体操作如下:

(1)定期更新台账数据,确保信息的准确性,该厂建立了完善的原材料采购和库存管理制度,对原材料进行实时监控和管理。 (2)加强数据安全管理,采用加密技术、数据备份等措施,确保数据安全可靠,建立了数据使用审批制度,防止数据滥用和泄露。 (3)强化团队协作与沟通,建立生产协调小组,定期召开生产会议,及时解决生产过程中的问题,加强与其他部门的沟通协作,确保生产计划的顺利实施。 (4)通过成本核算与分析,该厂发现生产成本过高的问题,及时采取措施进行成本控制和优化,为质量控制提供了有力支持,最终实现了生产效益的提高和生产流程的优化。

总结与展望

通过本次讨论,我们了解了纺织厂生产台账的重要性及其在实际操作中的运用,在未来的工作中,纺织厂应进一步加强台账管理,提高生产效率和质量,应不断探索和创新台账管理方法和技术,为纺织行业的发展做出更大的贡献。

Articles related to the knowledge points of this article:

The Glitz and Glamour of Chinas Textile Mill Women