The Causes of Downsizing in the Textile Industry

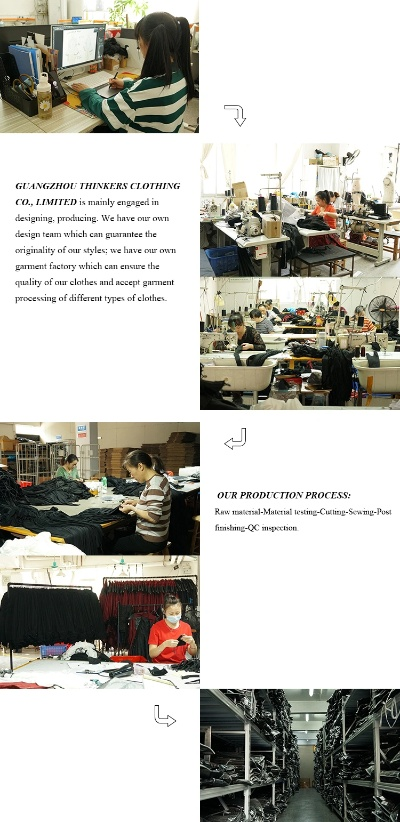

Downsizing, a significant trend in the textile industry, is driven by various factors. One major factor is the changing consumer demand for clothing and accessories. With the rise of eco-friendly fashion, consumers are increasingly seeking out sustainable materials and minimalistic designs. Additionally, technological advancements have led to increased efficiency in production processes, making it more economical for companies to produce smaller quantities of high-quality goods. Another driving force behind downsizing is the pressure to reduce costs and increase profitability. As competition intensifies, companies must find ways to streamline operations and cut expenses, often resulting in reduced product sizes. Finally, government policies and regulations can also influence downsizing trends. For example, stringent environmental standards and labor laws may require companies to produce smaller batches of goods, leading to a shift towards more efficient and cost-effective production methods. Overall, the causes of downsizing in the textile industry are complex and multifaceted, reflecting both market forces and societal concerns.

In the textile industry, downsizing is a common phenomenon that has been affecting many factories worldwide. This article will explore the main reasons behind this trend and provide some insights into how it affects workers and the industry as a whole.

One of the primary reasons for downsizing in the textile industry is economic pressure. With global competition becoming increasingly fierce, companies are forced to cut costs wherever possible. One way they do this is by reducing the workforce, which can lead to layoffs or restructuring of the company. For example, according to a report by the International Labour Organization (ILO), there were over 3 million textile workers around the world in 2019, but this number has been steadily decreasing since then.

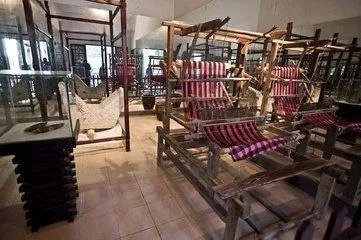

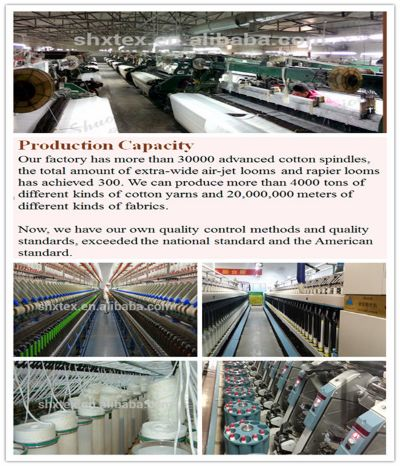

Another reason for downsizing is technological advancements. As technology continues to improve, new machines and processes become more efficient than traditional ones. This means that some jobs may become obsolete, leading to job losses. For instance, the introduction of automated machines in the textile industry has led to a significant reduction in manual labor jobs.

Environmental concerns also play a role in downsizing. Many textile factories have been criticized for their negative impact on the environment, such as air and water pollution. To address these concerns, many companies are adopting more sustainable practices, such as using renewable energy sources and reducing waste. However, this shift towards sustainability may lead to job losses as some workers may be replaced by machines or other forms of automation.

Competition from other industries is also a major factor in downsizing. As demand for textile products decreases, companies may need to reduce their workforce in order to stay profitable. For example, the decline in demand for denim jeans has led to a significant reduction in production at many denim mills.

To understand the impact of downsizing on workers, we can look at an example from China. According to a report by the World Bank, there were over 1 million textile workers in China in 2018, but this number has been decreasing steadily since then. The reason for this is that many factories have closed down due to downsizing, leading to job losses for many workers.

In addition to job losses, downsizing can also have long-term effects on the industry. For example, when a company closes its doors, it may lose access to valuable resources such as machinery and equipment. This can make it difficult for other companies to enter the industry and compete with them.

Overall, downsizing is a complex issue that affects both workers and the industry as a whole. While it may seem like a good idea to save money by reducing costs, it can have negative consequences for both employees and customers. It is important for companies to carefully consider the impact of downsizing on their workers and the environment before making any decisions.

尊敬的听众朋友们,今天我们来探讨一下纺织厂下岗的原因,随着时代的变迁,许多行业都面临着转型升级的压力,纺织行业也不例外,我们将从多个角度来分析纺织厂下岗的原因。

背景介绍

纺织厂作为我国传统产业的重要组成部分,承担着生产制造、出口贸易等多重任务,近年来,随着市场竞争加剧和技术升级的推动,纺织厂面临着诸多挑战,一些纺织厂因为种种原因而不得不进行转型升级,实施下岗或重组。

原因分析

市场环境变化

市场环境的变化是导致纺织厂下岗的主要原因之一,随着全球化和互联网的快速发展,消费者需求日益多样化,对纺织品的质量和性能要求也越来越高,国际贸易保护主义抬头,使得纺织品的出口压力增大,这些因素都使得纺织厂在市场竞争中处于不利地位,不得不进行转型升级。

产业结构调整

产业结构调整也是纺织厂下岗的重要原因之一,随着国家对产业结构调整的推进,一些传统纺织企业面临着生产效率低下、技术落后、环保压力大的问题,为了适应市场需求和转型升级的需要,这些企业不得不进行裁员或重组。

企业管理不善

企业管理不善也是导致纺织厂下岗的原因之一,一些纺织厂的领导层在管理上存在诸多问题,如缺乏有效的激励机制、员工培训不足、生产流程不合理等,这些问题导致员工的工作积极性不高,生产效率低下,最终不得不进行转型升级。

案例说明

为了更好地理解纺织厂下岗的原因和过程,我们可以结合一些具体的案例来进行说明,以下是一个可能的案例:

某纺织厂在过去几年中面临着巨大的经营压力和转型升级的压力,由于市场竞争加剧和技术升级的推动,该厂的生产效率低下、技术落后、环保压力大,为了应对这些问题,该厂决定进行转型升级,实施下岗或重组,经过一段时间的努力,该厂成功转型为智能制造工厂,提高了生产效率和质量,同时也降低了环保压力,在这个过程中也出现了一些问题,如员工安置、债务处理等,为了解决这些问题,该厂采取了一系列措施,如与政府合作、引入先进技术等,最终成功实现了转型升级。

表格补充说明

以下是关于纺织厂下岗原因的表格补充说明:

| 因素 | 具体案例说明 |

|---|---|

| 市场环境变化 | 随着全球化和互联网的快速发展,市场竞争加剧,出口压力增大 |

| 产业结构调整 | 一些传统纺织企业面临生产效率低下、技术落后、环保压力大等问题 |

| 企业管理不善 | 领导层管理不善,缺乏有效的激励机制、员工培训不足、生产流程不合理等 |

| 下岗原因总结 | 为了应对市场竞争和转型升级的压力,一些纺织厂不得不进行裁员或重组 |

纺织厂下岗的原因是多方面的,市场环境变化、产业结构调整、企业管理不善等因素都是导致纺织厂下岗的主要原因,为了应对这些问题,纺织厂需要采取一系列措施进行转型升级和员工安置等工作,政府和社会也应该给予更多的支持和帮助,促进纺织行业的健康发展。

Articles related to the knowledge points of this article:

The Transformation of Gantang Textile Mill:A Journey Towards Sustainability