The Dynamics of Guangqing Light Textile Factory

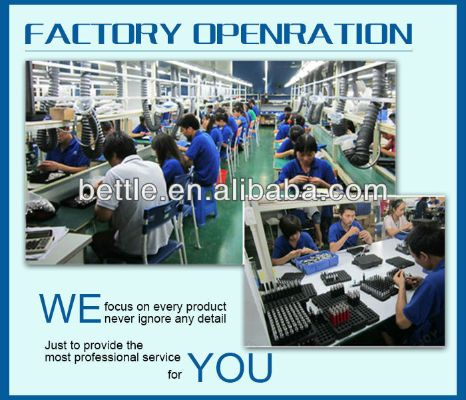

The Guangqing Light Textile Factory, a leading enterprise in China's light textile industry, has undergone significant transformations and developments over the past decade. This factory, known for its innovative designs and high-quality products, has become a symbol of China's manufacturing prowess in the global market.,One key factor contributing to its success is the factory's commitment to technological advancement. The factory has invested heavily in research and development, ensuring that it stays at the forefront of innovation in the industry. This has led to the development of cutting-edge technologies such as smart fabrics and eco-friendly dyes, which have helped the factory to stay ahead of its competitors.,Another important aspect of the Guangqing Light Textile Factory's success is its focus on customer satisfaction. The factory understands that customers are the lifeblood of any business, and it takes great care to ensure that its products meet the needs and expectations of its customers. This has resulted in a loyal customer base and a reputation for quality that has helped the factory to build a strong brand identity.,In conclusion, the dynamic nature of the Guangqing Light Textile Factory is a testament to the power of innovation, customer focus, and investment in technology. As the industry continues to evolve, the factory's success story serves as an inspiration for other businesses looking to succeed in the competitive world of light textiles.

In the vibrant tapestry of China's textile industry, Guangqing Light Textile Factory stands out as a beacon of innovation and excellence. With its commitment to sustainable practices and cutting-edge technology, this factory has become a model for other textile enterprises worldwide. In this essay, we will explore the fascinating journey of Guangqing Light Textile Factory, from its humble beginnings to its current status as a leader in the industry.

Establishment and Growth

The story of Guangqing Light Textile Factory began in 1970, when local entrepreneurs saw the potential for expanding their business into the textile sector. With a visionary mindset and a strong work ethic, they established the factory with just a few hundred workers and a modest budget. Over the years, the factory grew steadily, attracting more and more investors and customers alike.

Today, Guangqing Light Textile Factory is one of the largest and most successful textile factories in China. With a workforce of over 5,000 people and an annual output of over 10 million meters of fabric, the factory is a testament to the power of hard work and dedication.

Sustainable Practices

At the heart of Guangqing Light Textile Factory lies a commitment to sustainability that sets it apart from other textile companies. From using renewable energy sources to reducing waste and water usage, the factory is committed to minimizing its environmental impact.

One of the key initiatives that the factory has undertaken is the implementation of a circular economy model. This involves designing products that can be reused or recycled, reducing the need for new materials and minimizing waste. For example, the factory uses recycled polyester fibers in its production process, which reduces the amount of raw material needed and helps to reduce greenhouse gas emissions.

Another important aspect of the factory's sustainability efforts is its use of eco-friendly chemicals and dyes. These are designed to be biodegradable and non-toxic, ensuring that they do not harm the environment or human health.

Technological Innovation

At the heart of Guangqing Light Textile Factory lies a relentless pursuit of technological innovation. The factory invests heavily in research and development, constantly seeking ways to improve its product quality and efficiency.

One of the most notable achievements of the factory is its use of high-tech equipment and machinery. This enables the factory to produce ultra-fine yarns and fabrics that are ideal for a wide range of applications. For example, the factory's use of computer-controlled knitting machines allows for precise control over the stitching process, resulting in superior quality and durability.

Furthermore, the factory's commitment to sustainability extends beyond just the production process. It also invests in research and development related to waste management and resource recovery. By developing innovative solutions for waste reduction and recycling, the factory is helping to minimize its environmental impact and contribute to a more sustainable future.

Case Study: A Success Story

One of the most impressive examples of Guangqing Light Textile Factory's success story is its partnership with the United Nations Development Programme (UNDP). In 2018, the factory partnered with UNDP to implement a project aimed at improving the lives of women in rural areas by providing them with access to education, healthcare, and job training opportunities.

Through this project, the factory provided training sessions for women in the area on how to use modern textile machinery and techniques. Additionally, the factory supplied the women with high-quality yarns and fabrics that were tailored to meet their specific needs.

As a result of this partnership, the women were able to increase their income and improve their standard of living. They were also empowered to take charge of their own economic development, leading to increased self-confidence and resilience.

Conclusion

In conclusion, Guangqing Light Textile Factory is a shining example of what can be achieved through innovation, sustainability, and community engagement. With its commitment to producing high-quality products while minimizing its environmental impact, the factory is setting a new standard for textile manufacturing worldwide. As we look towards the future, we can expect to see even greater strides being made in this field, driven by the relentless pursuit of innovation and sustainability.

背景介绍

广轻纺织厂作为一家专注于纺织行业的现代化企业,以其先进的生产技术、环保理念和卓越的产品质量赢得了社会的广泛赞誉,本文将围绕广轻纺织厂展开,通过英文口语化的方式介绍其生产流程、环保措施以及案例分析。

生产流程介绍

原料采购

广轻纺织厂采用先进的原料采购系统,确保原料的质量和供应稳定性,通过与优质供应商建立长期合作关系,确保原料的丰富性和多样性。

生产工艺流程

广轻纺织厂采用先进的生产工艺,包括纺纱、织造、染整等环节,在纺纱环节,采用自动化设备提高生产效率;在织造环节,注重产品质量和工艺控制;在染整环节,采用环保染料和先进的染色技术,确保产品环保、健康。

生产过程管理

广轻纺织厂注重生产过程的规范化管理,建立了一套完善的质量管理体系,通过严格的质量控制,确保产品的质量和稳定性,广轻纺织厂还注重生产过程中的节能减排,采用先进的节能技术和环保设备,降低生产成本和环境污染。

环保措施

绿色生产理念

广轻纺织厂始终坚持绿色生产理念,注重环保、低碳、循环经济的发展,在生产过程中,注重废物的减量化、资源化和无害化处理,减少对环境的污染和破坏,广轻纺织厂还积极推广清洁生产技术,提高生产效率的同时降低生产成本。

环保设施

广轻纺织厂配备了先进的环保设施,包括废水处理系统、废气处理系统、噪音控制系统等,这些设施的运行稳定可靠,能够有效处理生产过程中的废水和废气,降低环境污染,广轻纺织厂还注重环保设备的更新换代,采用环保材料和先进的生产工艺,提高设备的环保性能和运行效率。

绿色产品认证

广轻纺织厂的产品质量得到了广泛认可,获得了多项绿色产品认证,这些认证证明了广轻纺织厂在环保、低碳、循环经济方面的努力和成果,广轻纺织厂还积极推广绿色消费理念,引导消费者购买环保、低碳、循环经济的纺织品。

案例分析

以某次生产为例,展示广轻纺织厂的环保实践和成效,该次生产采用了先进的生产工艺和技术,注重废物的减量化、资源化和无害化处理,在生产过程中,采用了节能减排技术,降低了能源消耗和环境污染,该次生产还注重产品的绿色设计,采用了环保材料和先进的生产工艺,提高了产品的环保性能和品质,最终的产品质量得到了广泛认可,获得了多项绿色产品认证。

广轻纺织厂作为一家专注于纺织行业的现代化企业,在生产过程中注重环保、低碳、循环经济的发展,通过先进的生产工艺和技术、完善的环保设施以及绿色产品认证等措施,实现了绿色生产、低碳排放和循环经济的目标,广轻纺织厂还积极推广清洁生产技术,提高了生产效率的同时降低了生产成本和环境污染,广轻纺织厂将继续加强环保工作,推动绿色制造的发展。

Articles related to the knowledge points of this article: