The Art of Textile Quality Inspection:A Comprehensive Guide

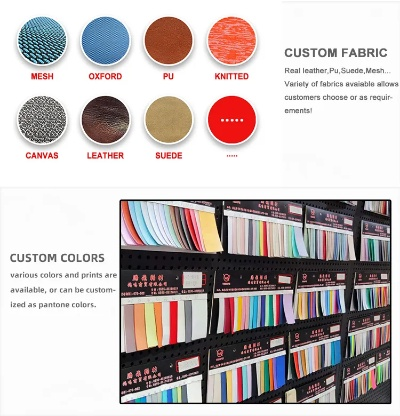

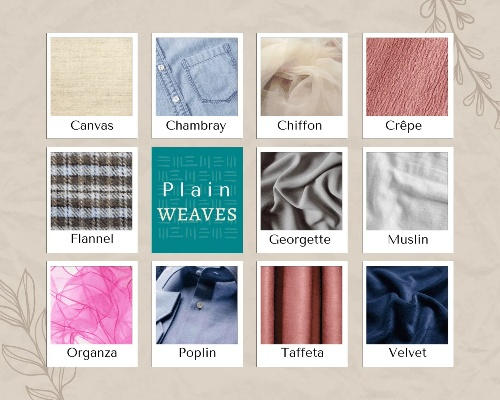

: The Art of Textile Quality Inspection: A Comprehensive Guide,In the realm of textile manufacturing, the art of quality inspection is paramount to ensuring the product meets consumer expectations and industry standards. This comprehensive guide aims to provide a thorough understanding of the various techniques and methods used in textile quality inspection, from initial inspection to final testing.,The first step in quality inspection involves visual examination of the raw materials used in the production process. This includes assessing the color, texture, and overall appearance of the fabric, as well as any defects or irregularities that may affect its functionality or aesthetic appeal.,Once the raw materials have been inspected, the next step is to perform a series of tests on the fabric itself. These tests include measuring its dimensions, checking for any imperfections or flaws, and evaluating its strength and durability. Additionally, it is important to test the fabric for any harmful chemicals or substances that may be present, as these can pose health risks to consumers.,Finally, once all of the above steps have been completed, the textile product must undergo rigorous testing to ensure it meets the highest standards of quality and safety. This includes testing for flame resistance, water repellency, and other relevant properties that are essential for its intended use.,By following this comprehensive guide, manufacturers can effectively implement quality inspection procedures that not only meet but exceed industry standards and consumer expectations.

Introduction: Quality inspection is the cornerstone of any textile production process. It ensures that products meet industry standards and consumer expectations. In this guide, we will explore the various aspects of textile quality inspection, including testing methods, sample preparation, and data analysis. We will also discuss some common challenges faced by textile manufacturers and how to overcome them. By the end of this guide, you will have a solid understanding of the importance of quality inspection in the textile industry and how to implement it effectively.

Testing Methods: Textile quality inspection involves several different methods, each with its own strengths and weaknesses. Here are some of the most common ones:

-

Visual Inspection: This method involves examining the surface of the fabric for defects such as tears, holes, or discoloration. It is quick and easy to perform but can be subjective and prone to human error.

-

Density Testing: This method measures the thickness and density of the yarns and fabrics. It is used to ensure that the product meets specifications for weight, length, and width.

-

Tensile Testing: This method tests the strength and flexibility of the fabric. It is used to determine whether the product can withstand wear and tear over time.

-

Compression Testing: This method simulates the effects of wear and tear on the fabric by applying pressure. It is used to measure the elasticity and resilience of the fabric.

-

Heat Stability Testing: This method assesses the resistance of the fabric to heat damage. It is used to ensure that the product can withstand high temperatures without losing its integrity.

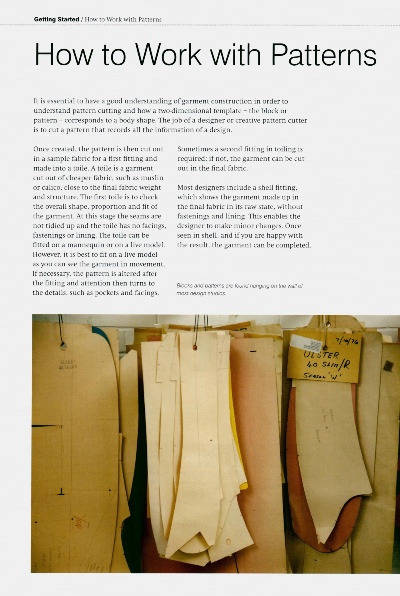

Sample Preparation: When conducting quality inspections, it's important to prepare samples that accurately represent the entire batch. Here are some tips for preparing samples:

-

Choose representative samples: Select samples that are representative of the entire batch. Avoid selecting samples that may have been damaged during processing or transport.

-

Follow standardized procedures: Use standardized procedures for sample preparation and handling to ensure consistency and accuracy.

-

Keep samples dry and clean: Ensure that samples are kept dry and free from contaminants that could affect their quality.

Data Analysis: Once the quality inspection results are collected, they need to be analyzed to identify any issues with the product. Here are some ways to analyze data:

-

Data visualization: Use charts and graphs to visualize the data and identify trends and patterns.

-

Statistical analysis: Use statistical methods to analyze the data and identify outliers and other anomalies.

-

Machine learning: Use machine learning algorithms to analyze large volumes of data and identify potential issues before they become problems.

Challenges Faced by Manufacturers: While quality inspection is crucial for ensuring product quality, manufacturers often face several challenges when implementing it:

-

Cost: Quality inspection can be expensive, especially for small-scale manufacturers who may not have the resources to invest in advanced equipment.

-

Time: Quality inspection takes time, which can be a challenge if manufacturers need to produce multiple batches of products simultaneously.

-

Training: Manufacturers need to invest in training their staff to ensure that they understand how to perform quality inspections correctly.

-

Regulations: Manufacturers must comply with regulations set by regulatory bodies, which can add additional layers of complexity to quality inspection processes.

Conclusion: Quality inspection is essential for ensuring that textile products meet consumer expectations and industry standards. By following the testing methods outlined above, preparing samples using standardized procedures, and analyzing data using appropriate techniques, manufacturers can identify potential issues before they become problems. While there may be challenges to overcome, investing in quality inspection is ultimately worth the investment in terms of customer satisfaction, brand reputation, and long-term success.

随着人们对纺织品的需求日益增长,纺织品的质量检验显得尤为重要,本篇报告将围绕纺织品质量检验的主题展开,通过英文案例说明和表格补充说明,为大家提供专业的纺织品质量检验方法和流程。

纺织品质量检验的重要性

纺织品质量检验是确保纺织品符合相关标准和规定的重要手段,通过质量检验,可以确保纺织品在生产、加工、运输和使用等各个环节的质量稳定性和可靠性,纺织品质量检验也是保障消费者权益的重要环节,可以避免因质量问题导致的纠纷和投诉。

纺织品质量检验的方法和流程

样品采集与准备

在纺织品质量检验过程中,首先需要采集样品,样品应该具有代表性,能够反映整个批次或产品的质量情况,在采集样品时,需要注意样品的状态、规格、数量等要素,需要准备好相关的检验工具和设备,以确保检验过程的顺利进行。

检测仪器与设备

纺织品质量检验需要使用各种检测仪器和设备,如拉力试验机、密度计、色牢度测试仪等,这些仪器和设备需要经过校准和检测,以确保其准确性和可靠性,还需要根据样品的特点和检验要求,选择合适的检测方法和技术。

检验步骤

(1)外观检查:检查样品的外观是否符合标准要求,包括颜色、纹理、尺寸等。

(2)化学成分分析:对样品的化学成分进行检测,包括纤维成分、染色成分等,可以使用各种化学分析方法,如元素分析、色谱分析等。

(3)机械性能检测:对样品的机械性能进行检测,包括拉伸强度、撕裂强度、耐磨性等,可以使用各种机械性能测试仪器,如拉力试验机、摩擦试验机等。

(4)质量标准与判定:根据样品的特点和质量标准,确定检验结果是否合格,需要制定相应的判定标准,以便于快速准确地判断样品的质量情况。

案例说明

以某品牌纺织品为例,进行纺织品质量检验的案例说明,该品牌纺织品采用了高质量的原材料和先进的生产工艺,具有较高的品质和稳定性,在质量检验过程中,首先采集了样品并进行外观检查,发现样品外观符合标准要求,接着进行了化学成分分析,发现纤维成分和染色成分均符合标准要求,最后进行了机械性能检测,发现样品的拉伸强度和耐磨性均符合相关标准。

纺织品质量检验的注意事项

-

严格按照标准进行检验,确保检验结果的准确性和可靠性。

-

确保样品具有代表性,能够反映整个批次或产品的质量情况。

-

使用经过校准和检测的仪器和设备,确保检验过程的顺利进行。

-

注意样品的状态、规格、数量等要素,确保样品采集的完整性和准确性。

纺织品质量检验是确保纺织品符合相关标准和规定的重要手段,通过正确的检验方法和流程,可以确保纺织品的质量稳定性和可靠性,我们需要注意样品采集与准备、检测仪器与设备的使用以及注意事项等方面,以确保纺织品质量检验的顺利进行和准确无误。

Articles related to the knowledge points of this article: