The Duties of a Textile Quality Inspection Station

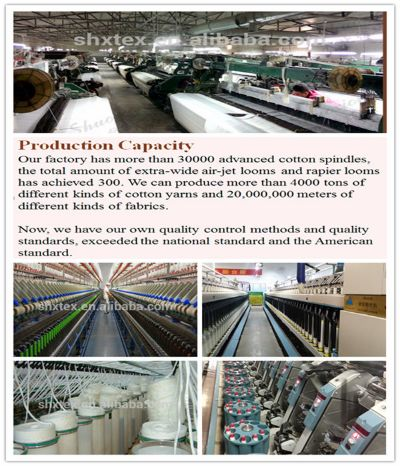

: The Duties of a Textile Quality Inspection Station,In the textile industry, the role of a textile quality inspection station is crucial in ensuring the quality and consistency of products. This station plays a critical role in identifying defects, verifying compliance with standards, and providing feedback to manufacturers for improvement. The responsibilities of a textile quality inspection station include:,1. Conducting regular inspections of raw materials, fabrics, and finished products to identify any defects or deviations from standards.,2. Verifying that products meet industry-specific quality standards and regulations, such as those set by international organizations like ISO.,3. Providing technical support to manufacturers during the production process to help them identify and correct any issues before they become defective products.,4. Analyzing data collected during inspections to identify trends and patterns that may indicate potential quality issues or areas for improvement.,5. Ensuring that inspection equipment is regularly maintained and calibrated to ensure accurate results and minimize errors.,6. Collaborating with other departments within the textile company, such as design and production, to ensure that quality standards are consistently met throughout the entire manufacturing process.

Introduction: In the world of textiles, quality is paramount. This is where the role of the textile quality inspection station comes into play. These stations are responsible for ensuring that the fabrics and materials used in clothing, home furnishings, and other textile products meet the highest standards of excellence. In this article, we will explore the various duties of a textile quality inspection station, including their roles in identifying defects, ensuring compliance with standards, and maintaining the integrity of the industry.

Roles and Responsibilities:

-

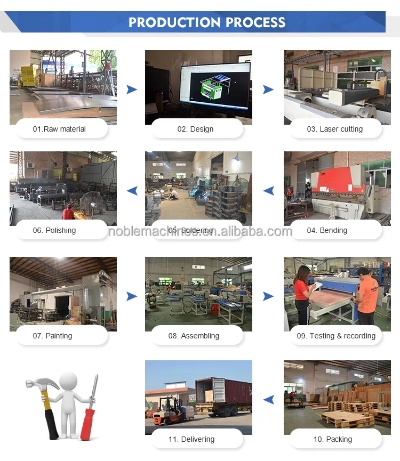

Pre-Production Inspection: A textile quality inspection station's first task is to inspect raw materials before they go on to production. This includes checking for any defects in the yarn or fabric, such as breaks, frays, or holes. Additionally, it involves verifying that the materials meet the required specifications, including weight, thickness, and color consistency.

-

Production Monitoring: As the production process progresses, the inspection station must closely monitor the quality of each step. This includes spot checks during the weaving, knitting, or crocheting process. Any issues identified during this stage can be addressed before the final product leaves the factory.

-

Post-Production Inspection: Once the finished product is ready for sale, the inspection station performs post-production inspections. This involves testing the fabric for proper dyeing, shrinkage, and wear resistance. It also includes visual inspections for any flaws or irregularities that may affect the product's appearance or performance.

-

Compliance Checks: The inspection station is responsible for ensuring that all products meet relevant standards and regulations, such as those set by international organizations like the International Organization for Standardization (ISO) or the United States Consumer Product Safety Commission (CPSC). They regularly audit these standards to ensure that their products comply with them.

-

Customer Feedback: The inspection station collects customer feedback on their products. This information is crucial for understanding how well the products are performing and for identifying areas for improvement. By addressing customer concerns promptly, the station can enhance customer satisfaction and loyalty.

-

Training and Education: The quality inspectors at the station must stay up-to-date on the latest techniques and technologies for detecting defects. They receive ongoing training to keep their skills sharp and to ensure that they can identify new challenges in the industry.

Case Study: One example of a successful textile quality inspection station is the one at the Texel Manufacturing Company in Texas. The company has implemented a comprehensive quality control system that includes regular pre-production inspections, close monitoring during production, and thorough post-production testing. As a result, Texel Manufacturing has consistently met and exceeded customer expectations for quality and safety standards.

Conclusion: In conclusion, the textile quality inspection station plays a critical role in ensuring that textile products meet high standards of excellence. By performing pre-production, production, and post-production inspections, as well as complying with relevant standards and regulations, these stations help to safeguard consumers from defective products. With ongoing training and education, they remain at the forefront of innovation and excellence in the textile industry.

纺织品质量检测站工作职责概述

纺织品质量检测站是负责纺织品质量检测、评估和监督的重要机构,其主要工作职责包括但不限于以下几个方面:

- 纺织品原料检测:对进厂的纺织品原料进行全面检测,确保其符合相关标准和安全要求。

- 产品质量控制:对生产出的纺织品进行质量检测,确保其符合相关质量标准。

- 数据分析与报告:对检测数据进行深入分析,形成详细的检测报告,为相关部门提供准确的质量信息。

- 质量控制体系建立与维护:制定并执行质量控制体系,确保检测工作的规范性和有效性。

具体工作流程与案例说明

纺织品原料检测流程

(1)原料接收:接收来自供应商的纺织品原料,进行数量和质量检查。 (2)样品预处理:对检测样品进行清洗、整理、分类等预处理工作。 (3)化学成分分析:使用各种检测仪器和方法,对纺织品原料的化学成分进行检测,确保其符合相关标准和安全要求。 (4)微生物检测:对纺织品原料进行微生物检测,确保其无有害微生物污染。 (5)报告生成:根据检测结果,生成详细的检测报告,为相关部门提供准确的质量信息。

某纺织品质量检测站成功检测某品牌纺织品原料的质量情况

某纺织品质量检测站近期成功检测了一批来自知名品牌供应商的纺织品原料,该批次原料经过严格的品质控制流程,包括原料接收、样品预处理、化学成分分析和微生物检测等环节,在检测过程中,该站严格按照相关标准和安全要求进行操作,确保了检测结果的准确性和可靠性,该批次纺织品原料的质量符合相关标准和安全要求,为该品牌赢得了良好的市场声誉。

产品质量控制流程与案例分析

(1)质量控制计划制定:制定详细的质量控制计划,明确质量控制的目标和要求。 (2)样品抽检:对生产出的纺织品进行抽检,确保其符合质量标准。 (3)质量监测与数据分析:对抽检样品进行实时监测,分析其质量情况,根据监测结果,制定相应的改进措施,对检测数据进行深入分析,形成详细的检测报告,为相关部门提供准确的质量信息。

某纺织企业通过质量控制体系提高产品质量水平

某纺织企业通过建立和完善质量控制体系,提高了产品质量水平,该企业制定了详细的质量控制计划,明确了质量控制的目标和要求,该企业加强了对原材料的采购、生产过程的管理和成品检验等环节的质量控制,在质量控制过程中,该企业注重数据分析与报告的生成,及时发现问题并采取相应的改进措施,该企业的产品质量得到了显著提高,赢得了良好的市场声誉。

纺织品质量检测站是保障纺织品质量的重要机构,其工作职责包括纺织品原料检测、产品质量控制和数据分析与报告等环节,在具体工作流程中,需要严格按照相关标准和安全要求进行操作,确保检测结果的准确性和可靠性,需要注重质量控制体系的建立与维护,确保检测工作的规范性和有效性,通过案例分析可以看出,建立和完善质量控制体系对于提高纺织品质量水平具有重要意义。

Articles related to the knowledge points of this article:

Trend Analysis of Prices in Xuhui District Textile Markets

The Journey of Overseas Textile Brands:A Case Study on 朱学兰纺织品

Textile Design with Side Profile

The Impact of Aerospace Textile Materials on Aircraft Performance and Cost