The Comprehensive Guide to Textile Inspection Standards for Quality Assurance

"The Comprehensive Guide to Textile Inspection Standards for Quality Assurance" is a comprehensive guide that provides detailed information on the various textile inspection standards for quality assurance. This guide covers all aspects of textile inspection, including color matching, pattern accuracy, fabric thickness, and more. It also includes information on how to use various tools and equipment for textile inspection, such as microscopes, calipers, and yarn testers. The guide provides clear instructions and step-by-step procedures for conducting textile inspections, ensuring that inspectors can effectively identify defects and ensure product quality. Overall, this guide is essential for anyone involved in textile inspection and quality assurance, providing valuable insights into the latest trends and best practices in the industry."

Introduction: In today's globalized marketplace, textile products are in high demand worldwide. However, the quality of these products is often subject to scrutiny, especially when it comes to regulatory standards and compliance with international regulations. This guide aims to provide an overview of the key textile inspection standards that are essential for ensuring product quality, safety, and legal compliance. We will explore the different types of inspections, their respective standards, and how they can help businesses stay ahead of regulatory challenges.

Types of Textile Inspections: Textile inspections can be broadly classified into two main categories: physical inspections and chemical/microbial tests.

-

Physical Inspections:

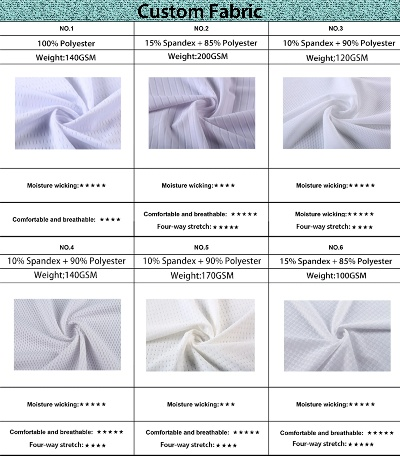

- Strict control over weight, length, width, and thickness of fabrics.

- Check for defects such as tears, holes, frays, and irregularities.

- Verification of stitching and seams for strength and durability.

- Evaluation of thread quality and colorfastness.

-

Chemical/Microbial Tests:

- Identification and quantification of harmful substances like lead, arsenic, and cadmium.

- Analysis of dyestuffs and finishes for toxicity and environmental impact.

- Examination of fabrics for microbial contamination, including bacteria and fungi.

- Testing for fire retardant properties and flame retardants content.

Standards for Textile Inspections: The following are some of the most widely recognized textile inspection standards:

- ASTM D4170: American Society for Testing and Materials (ASTM) - "Standard Test Method for Determining the Compression Set of Wool."

- ISO 13586: International Organization for Standardization - "Test Method for Determining the Compression Set of Cotton."

- EN 13942: European Committee for Standardization - "Compression set test method for cotton fabrics."

- GB/T 18342: China National Standard - "Compression set test method for cotton fabrics."

- AATCC 200: American Association of Textile Chemists - "Standard Test Method for Determining the Resistance to Burning of Textile Fabrics."

Case Study: Consider a company that manufactures high-quality sportswear using organic cotton. To ensure consumer safety and meet regulatory requirements, they must comply with various inspection standards. They might follow the ASTM D4170 standard for determining the compression set of wool, which helps assess the elasticity and recovery of the fabric after being stretched. Additionally, they would need to adhere to ISO 13586 for testing the compression set of cotton fabrics, which evaluates the degree to which fabrics return to their original shape after being compressed.

To ensure compliance with AATCC 200, the company could conduct tests on their organic cotton fabrics to determine the resistance to burning. These tests are crucial for assessing the fabric's flame retardant properties and ensuring that they do not release harmful chemicals during a fire. By following these standards, the company can demonstrate its commitment to quality, safety, and regulatory compliance, thereby gaining trust from consumers and stakeholders.

Conclusion: Textile inspection standards play a critical role in ensuring the quality and safety of textile products. By understanding the different types of inspections and their respective standards, businesses can effectively manage their quality control processes. It is essential to continuously update one's knowledge about emerging standards and regulations to remain compliant and competitive in the ever-evolving global textile industry.

随着纺织行业的快速发展,纺织品的质量和安全性越来越受到人们的关注,为了确保纺织品的质量和安全,必须进行严格的送检检测,本篇文章将详细介绍纺织品送检检测的规范标准,并结合实际案例进行说明。

纺织品送检检测规范标准概述

检测目的

纺织品送检检测的目的是为了确保纺织品符合相关标准和法规要求,保障人们的健康和安全。

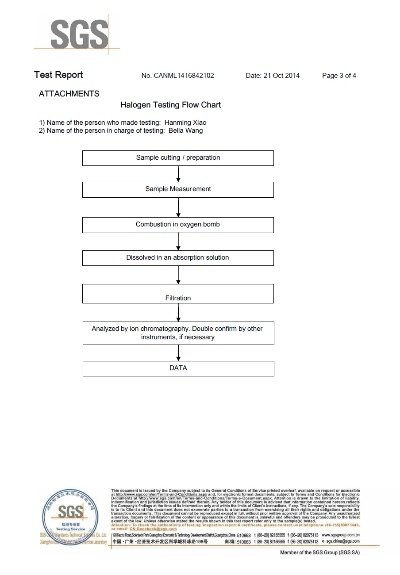

检测流程

(1)样品准备:按照检测需求,准备相应的样品。 (2)样品送检:将样品送至指定的检测机构进行检测。 (3)检测结果出具:检测机构出具检测报告,明确样品的质量和安全情况。

检测标准

(1)材质标准:纺织品应符合国家或行业标准规定的材质要求。 (2)安全标准:纺织品应符合相关法规和标准规定的安全要求。 (3)性能指标:纺织品应符合一定的性能指标,如耐热性、耐磨性、抗皱性等。

实际案例说明

某品牌纺织品送检检测流程

某品牌在生产过程中发现一批纺织品存在质量问题,遂委托第三方检测机构进行送检检测,检测机构接到委托后,按照规范标准对样品进行了检测,对样品进行材质检查,确保材质符合国家标准;对样品进行安全检查,确保符合相关法规和标准;根据性能指标进行检测,出具详细的检测报告,该品牌成功解决了纺织品质量问题,保障了消费者的健康和安全。

纺织品送检检测中遇到的问题及解决方案

在实际送检检测过程中,可能会遇到样品不符合要求、检测结果不准确等问题,针对这些问题,可以采取以下解决方案:一是加强样品管理,确保样品符合要求;二是优化检测流程,提高检测效率;三是加强与检测机构的沟通与合作,确保检测结果的准确性。

纺织品送检检测规范标准补充说明

材质标准补充说明

(1)材质应符合国家或行业标准规定的材质要求,确保产品的质量和安全性。 (2)对于特殊材质,应进行特殊处理或测试,以确保产品的性能和质量符合要求。

安全标准补充说明

(1)纺织品应符合相关法规和标准规定的安全要求,包括无毒、无害、无污染等。 (2)对于特殊用途的纺织品,应进行特殊的安全测试和认证,以确保产品的安全性能符合要求。

性能指标补充说明

(1)纺织品应具备一定的性能指标,如耐热性、耐磨性、抗皱性等,不同种类的纺织品应符合不同的性能指标要求。 (2)对于特殊用途的纺织品,应根据其使用场景和用途,确定相应的性能指标要求。

纺织品送检检测是保障纺织品质量和安全的重要手段,为了确保检测结果的准确性和可靠性,必须严格遵守纺织品送检检测规范标准,在实际操作中,应加强样品管理、优化检测流程、加强与检测机构的沟通与合作等措施,还应根据具体情况,补充说明材质标准、安全标准、性能指标等方面的具体要求。

Articles related to the knowledge points of this article:

The Standardization of Textile Dimensions and Its Impact on Global Trade

The Role of Textile Testing in Wuxi,China