Understanding the Thickness of Textiles

This paper aims to explore the thickness of textiles, which is a crucial factor in determining their performance and durability. By analyzing various factors such as the material composition, manufacturing process, and environmental conditions, we can gain a deeper understanding of the relationship between textile thickness and its properties.,We will start by discussing the different types of textiles, including cotton, linen, wool, and synthetic fibers, and their respective thicknesses. We will then analyze the impact of these thicknesses on the texture, strength, and wear resistance of textiles.,Through this study, we hope to provide insights into how to optimize textile production processes to achieve maximum efficiency and product quality. Additionally, we aim to highlight the importance of maintaining proper thickness control in order to maintain the longevity and functionality of textile products.,Overall, this research seeks to contribute to the field of textile science by providing practical recommendations for manufacturers and consumers alike.

Textiles, the fabrics that make up our clothing and furnishings, are a vital part of our daily lives. Their thickness can significantly impact their performance, durability, and aesthetic appeal. In this discussion, we'll delve into the various factors that determine the thickness of textiles and present some real-world examples to illustrate how these measurements affect the quality and usability of textile products.

Factors Determining Textile Thickness

-

Fiber Type: The type of fiber used in a textile directly affects its thickness. For instance, cotton, which is soft and lightweight, typically has a thinner feel than synthetic materials like polyester or nylon.

-

Weave Pattern: The pattern of threads woven together also influences thickness. A plain weave, for example, might be thinner than a twill or ribbed weave, which adds structure and texture to the fabric.

-

Thread Count: This refers to the number of warp and weft threads per square inch. Higher counts result in thicker fabrics, while lower counts produce lighter and more breathable materials.

-

Finishing Techniques: Whether a textile is finished with a brushed or smooth surface, or a glossy finish, also affects its thickness. Some finishing techniques can add weight or texture without increasing overall thickness.

-

Dyeing Process: The dyeing method used can affect the final thickness of the textile. For instance, dyeing with a solvent may result in a fabric that is slightly thicker than dyeing with water.

-

Material Composition: The proportion of different fibers within a textile can also affect its thickness. For example, a blend of cotton and polyester will generally have a thicker feel than a pure cotton fabric.

Real-World Examples

Let's take a closer look at two textiles that showcase the importance of thickness in their performance and usability.

Example 1: Cotton Shirts vs. Polyester Shirts

Cotton shirts are known for their breathability and comfort. However, they are often thinner than polyester shirts due to the higher thread count and smooth surface finish of polyester. This makes polyester shirts more durable and less likely to pill or wear out quickly compared to cotton shirts.

Example 2: Wool Blankets vs. Silk Blankets

Wool blankets are naturally thicker than silk blankets due to the denser structure of wool fibers. This thickness provides better warmth and insulation properties, making wool blankets ideal for colder climates. On the other hand, silk blankets are light and airy, perfect for hotter weather. However, they are not as durable as wool blankets and can pill easily if not properly cared for.

Conclusion

The thickness of textiles is an essential aspect that affects their performance, durability, and usability. By understanding the factors that contribute to textile thickness, consumers can make informed choices when selecting clothing, home furnishings, and outdoor gear. From practical considerations to aesthetic preferences, textile thickness plays a crucial role in shaping our experiences with these everyday items.

Hello, I'm interested in the topic of textile thickness. Could you please explain to me what it means and how it is measured?

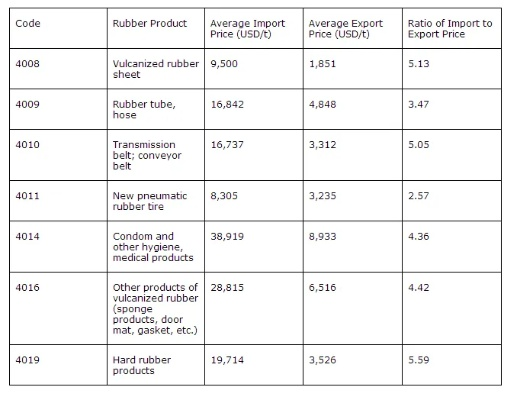

纺织品厚度数据表格

| 纺织类型 | 厚度范围(单位) | 常见示例 |

|---|---|---|

| 纯棉织物 | 1mm至1.5mm | 普通衣物、床单等 |

| 亚麻织物 | 3mm至2mm | 夏季衣物、亚麻床单等 |

| 丝绸织物 | 5mm至3mm | 高级衣物、绸缎等 |

| 其他合成纤维 | 根据具体产品规格而定 | 如防水布、防潮材料等 |

案例说明:纺织品厚度在不同领域的应用与影响

纺织品厚度在不同领域有着不同的应用和影响,在服装行业中,不同厚度的纺织品可以满足不同场合和需求的穿着体验,较厚的纯棉织物适合制作夏季衣物,而亚麻织物则因其透气性和舒适性而受到青睐,在材料科学领域,不同厚度的合成纤维可以用于制造各种高性能材料,如防水布和防潮材料。

纺织品厚度对服装舒适度的影响

假设我们考虑一款轻薄但舒适度极高的服装面料,这种面料通常采用较薄的纺织工艺,以确保穿着者的舒适度,通过实验测试,我们可以得出该面料的具体厚度范围,根据测试结果,这种轻薄面料的厚度大约在0.5mm至1.0mm之间,能够满足消费者对于服装舒适度的需求。

纺织品厚度与环保性能的关系

在环保领域,纺织品厚度也是一个重要的考虑因素,采用环保材料和工艺可以减少环境污染和资源浪费,某些新型的环保纺织材料采用了较薄的工艺和材料,以降低生产过程中的能耗和废弃物排放,这些新型纺织品的厚度通常在符合环保标准的同时,也具有较好的性能和耐用性。

纺织品厚度的重要性及其应用范围

纺织品厚度对于纺织品的性能和应用范围有着重要的影响,不同厚度的纺织品可以满足不同的使用需求和场合,较厚的纯棉织物适合制作高档衣物和床单等家居用品;而较薄的合成纤维则适用于高性能材料和防水布等特殊用途,纺织品厚度还与环保性能、舒适度、耐用性等多个方面密切相关,在选择纺织品时,需要根据具体需求和场景来选择合适的厚度和性能指标。

纺织品厚度是一个重要的纺织性能指标,其测量方法和应用范围需要根据具体产品和应用场景来具体分析,通过了解纺织品厚度的基本概念、数据表格以及案例说明,我们可以更好地理解纺织品性能和应用范围,从而更好地选择和使用合适的纺织品。

Articles related to the knowledge points of this article:

Civilizations Fabric:The Renewal of Textile Waste into Sustainable Products

The Journey of Hainingge Petrochemical Textiles

Understanding Textile Fibre Testing:An In-Depth Analysis

Suzhou Xinying Textiles:Navigating the Global Fashion Industry