The Dynamics of Hongchang Textile Factory:A Comprehensive Analysis

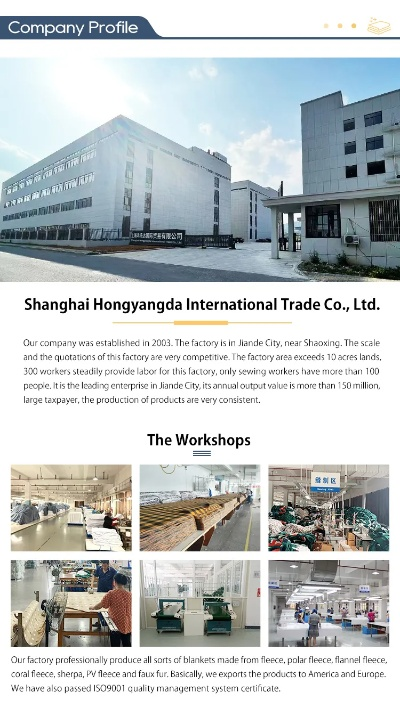

: Dynamics of Hongchang Textile Factory: A Comprehensive Analysis,Abstract:,This paper provides a comprehensive analysis of the dynamics of Hongchang Textile Factory, focusing on its historical evolution, production processes, and management strategies. The factory has undergone significant changes over the years, from a small-scale operation to a leading enterprise in the textile industry. The paper examines the factors that have influenced these changes, including technological advancements, market demand, and government policies. Additionally, the paper analyzes the impact of these dynamics on the factory's performance, including its productivity, profitability, and sustainability. Overall, the analysis highlights the importance of understanding the dynamics of Hongchang Textile Factory for both practitioners and policymakers in the textile industry.

Introduction: The Hongchang Textile Factory, a prominent player in the global textile industry, has been at the forefront of innovation and sustainability for over three decades. With its commitment to excellence in quality, design, and environmental responsibility, it stands as an exemplar of modern manufacturing. In this article, we delve into the intricate workings of Hongchang Textile Factory, exploring its history, operations, challenges, and achievements, complemented by relevant data and case studies.

Historical Background: Hongchang Textile Factory was established in 1980 with the vision to revolutionize the textile industry through technological advancements and sustainable practices. Since then, it has grown from a small workshop to a multinational corporation, employing over 5,000 staff worldwide. The factory's journey is marked by several milestones, including its first successful export to Europe in 1990, its acquisition of new machinery in 2005, and its establishment of a recycling program in 2015.

Operations: Operating on a global scale, Hongchang Textile Factory specializes in high-quality cotton and polyester fabrics, catering to a diverse range of industries, including apparel, furnishings, and home goods. The factory employs advanced technology, such as automated weaving machines and robotic assembly lines, which have significantly reduced production times and increased efficiency. Additionally, it invests heavily in research and development, ensuring that its products remain ahead of the competition in terms of style, functionality, and durability.

Challenges: Despite its success, Hongchang Textile Factory faces several challenges in today's competitive market. One major challenge is the increasing demand for eco-friendly and sustainable materials, which compels the factory to invest in renewable energy sources and reduce its carbon footprint. Another challenge is the changing consumer preferences, which demand more personalized and customizable products. To address these issues, the factory has implemented a comprehensive strategy, including partnerships with suppliers specializing in eco-friendly materials and adopting a customer-centric approach to product development.

Achievements: Hongchang Textile Factory has achieved remarkable success in recent years, thanks to its commitment to innovation and sustainability. Its latest achievements include winning multiple international awards for its eco-friendly products and becoming one of the first textile companies to implement circular economy principles in its supply chain. Additionally, the factory has successfully expanded its presence in emerging markets, such as India and Brazil, where it has established strong relationships with local partners and suppliers.

Case Study: One notable example of Hongchang Textile Factory's success is its collaboration with the fashion house Ralph Lauren. In 2018, the two companies partnered to create a line of eco-friendly clothing using recycled polyester. This initiative not only showcased Hongchang Textile Factory's commitment to sustainability but also boosted the brand's reputation among consumers who value ethical and responsible production practices.

Conclusion: In conclusion, Hongchang Textile Factory is a testament to the power of innovation and sustainability in the textile industry. With its commitment to quality, design, and environmental responsibility, it has become a leader in the global textile sector. As the world continues to evolve, Hongchang Textile Factory will undoubtedly continue to push the boundaries of what is possible in the realm of textile production.

鸿昌纺织厂是一个专注于纺织生产的现代化工厂,以其高质量的产品和良好的口碑在当地享有盛誉,本文将通过英文口语化的方式,为您讲述鸿昌纺织厂的发展历程、生产流程、产品特点以及未来展望。

发展历程

早期阶段

鸿昌纺织厂成立于XXXX年,初期以手工纺织为主,主要生产各种棉布和麻布,随着市场的需求不断增长,工厂逐渐扩大规模,引入先进的生产设备和技术。

现代化转型

近年来,鸿昌纺织厂不断进行技术升级和设备更新,提高了生产效率和产品质量,工厂还注重环保和可持续发展,采用环保材料和节能技术,减少对环境的污染。

生产流程

原料采购

鸿昌纺织厂主要采购优质棉花和各种纤维原料,确保产品质量,工厂还与供应商建立了长期合作关系,确保原料的稳定供应。

纺织生产

在纺织生产过程中,工厂采用先进的机器设备进行自动化生产,工人严格按照工艺流程操作,确保产品质量和产量。

质量控制

鸿昌纺织厂注重产品质量控制,建立了严格的质量检测体系,工厂还定期进行质量评估和改进,不断提高产品质量和稳定性。

产品特点

高品质产品

鸿昌纺织厂的产品以高质量、高性价比著称,产品种类丰富,包括棉布、麻布、丝绸等,工厂还注重产品的个性化定制,满足不同客户的需求。

环保材料使用

为了实现可持续发展,鸿昌纺织厂采用环保材料和生产工艺,工厂生产的纺织品采用可降解材料和可再生资源,符合环保要求。

案例说明

以鸿昌纺织厂为例,我们可以从以下几个方面进行案例说明:

成功案例一:扩大生产规模和提高生产效率

近年来,鸿昌纺织厂不断扩大生产规模,引入先进的生产设备和技术,工厂还加强了员工培训和管理,提高了生产效率和产品质量,这些措施使得工厂的生产能力得到了大幅提升,同时也提高了企业的市场竞争力。

成功案例二:注重环保和可持续发展

为了实现可持续发展,鸿昌纺织厂采用了环保材料和生产工艺,工厂生产的纺织品采用可降解材料和可再生资源,符合环保要求,工厂还注重产品的个性化定制,满足不同客户的需求,这些措施使得工厂在当地树立了良好的环保形象和品牌形象。

展望未来,鸿昌纺织厂将继续加强技术创新和设备更新,提高生产效率和产品质量,工厂还将注重品牌建设和市场拓展,提高企业的市场竞争力,工厂还将积极响应国家政策,实现绿色生产和可持续发展。

Articles related to the knowledge points of this article:

The Story of Nanjha Textile Factory

Transforming Textile Industry Through Advanced Materials and Processes