Understanding and Preventing Textile Shrinkage

: Understanding and Preventing Textile Shrinkage,Textile shrinkage is a common issue that affects the quality of clothing, fabrics, and other textile products. This paper aims to provide an overview of the causes and prevention methods for textile shrinkage.,The main causes of textile shrinkage include improper drying conditions, high temperature exposure, chemical treatments, and incorrect dyeing processes. These factors can cause the fibers to contract and reduce their size, resulting in uneven patterns and reduced durability.,To prevent textile shrinkage, it is important to choose appropriate drying conditions and avoid exposing the fabric to high temperatures or chemicals. Additionally, proper dyeing techniques and careful selection of materials can help minimize shrinkage.,In conclusion, understanding the causes and prevention methods for textile shrinkage is crucial for maintaining the quality and durability of textile products. By following proper drying and dyeing procedures and selecting appropriate materials, manufacturers can reduce the risk of shrinkage and ensure that their products meet consumer expectations.

Introduction: Textile shrinkage is a common issue faced by many textile manufacturers, designers, and consumers. This phenomenon occurs when the fabric contracts or loses volume after being washed, dried, or subjected to certain treatments. It can lead to uneven garment fit, poor appearance, and even structural damage if left unchecked. In this guide, we will explore the causes of textile shrinkage, its effects on products, and strategies for preventing it. We'll also provide an example of how to analyze a textile shrinkage case using a table.

Causes of Textile Shrinkage:

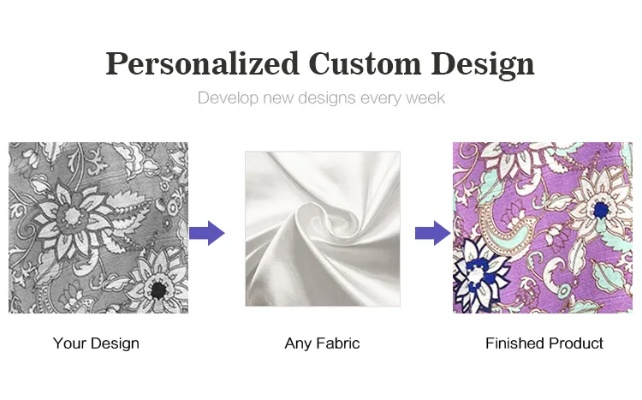

- Chemical Treatments: Many textiles undergo chemical treatments like dyeing, finishing, or printing that can cause shrinkage. These chemicals react with the fibers, altering their structure and causing them to contract.

- Moisture Content: High moisture content in the fabric can lead to increased shrinkage during washing and drying processes. The water molecules penetrate into the fibers, causing them to contract.

- Heat Treatments: Extreme heat can denature the fibers, making them more porous and susceptible to shrinkage. This effect is especially pronounced in synthetic fibers.

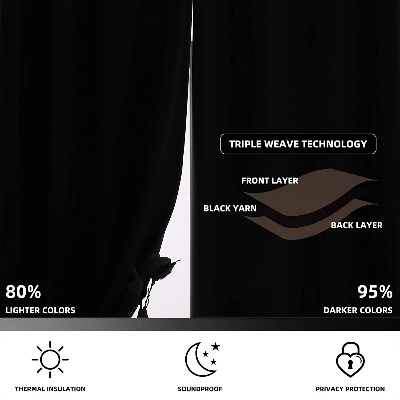

- Fabric Construction: The way fabric is woven or knitted can affect its ability to retain moisture and shrink less. For instance, tighter weaves may allow more air to circulate, reducing shrinkage.

- Ageing: Over time, textiles can age, losing their elasticity and resilience, leading to increased shrinkage.

Effects of Textile Shrinkage:

- Uneven Fit: Shrinkage can cause clothes to become looser or tighter than they originally were, affecting the wearer's comfort and appearance.

- Decreased Durability: Chronic shrinkage can lead to weaker fabrics, making them prone to tearing or fraying over time.

- Loss of Warmth: Some materials, such as wool, tend to lose warmth faster due to shrinkage, which can be a significant issue in cold weather.

- Structural Deterioration: Severe shrinkage can cause tears or holes in the fabric, leading to structural failure.

Preventing Textile Shrinkage:

- Choose Fiber Type: Selecting fibers that are known for their resistance to shrinkage can help minimize the risk of shrinkage during manufacturing and use.

- Reduce Moisture Content: Ensure that the fabric does not come into contact with excessive moisture before washing or drying. Use air circulation techniques during these processes to reduce moisture buildup.

- Control Heat Treatments: Avoid high temperatures during fabric processing to prevent denaturation of fibers and subsequent shrinkage.

- Use Proper Weaving Techniques: Tighter weaves can improve breathability and reduce shrinkage. Consider using natural fibers that have inherently low shrinkage rates.

- Regular Maintenance: Regular cleaning and care instructions should be followed to maintain the fabric's resilience and minimize shrinkage risks.

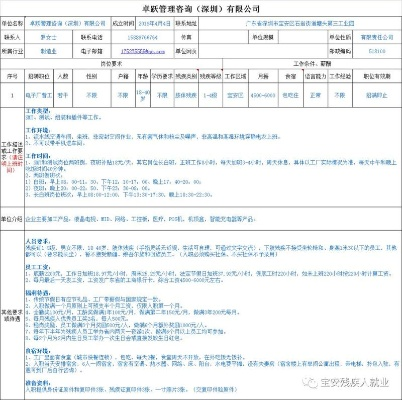

Case Study: Let's take a look at a real-world scenario where textile shrinkage led to a significant problem for a clothing brand. The company was producing shirts made from a blend of polyester and cotton. Despite following standard production procedures, the shrinkage rate was higher than expected for the polyester component. As a result, the shirts became too tight and uncomfortable for the end consumer.

Analysis Using a Table: To analyze this case, we could create a table summarizing the factors contributing to the higher shrinkage rate in the polyester component. The table would include details about the specific polyester blend used, the temperature and humidity conditions during processing, any additives or treatments applied, and any changes in the fabric's construction or weaving technique.

Conclusion: Textile shrinkage is a complex issue that requires careful consideration of various factors during manufacturing and use. By understanding the causes and effects of shrinkage, businesses can implement preventative measures to minimize the risk of shrinkage-related problems. In the case study, addressing the issue through a thorough analysis and adjustments to the production process led to improved product quality and customer satisfaction.

纺织品在生产过程中常常会遇到缩水问题,本文将通过图表和案例说明来深入解析纺织品缩水的原理及其应对措施。

缩水原理图解

缩水原因分析

缩水现象通常是由于纺织品在加工过程中受到机械、化学或热力等因素的影响,导致纤维变形或收缩,具体原因可能包括纤维材质差异、加工条件不当、温度湿度控制不当等。

(表格1)

缩水过程展示

缩水过程可以通过以下图表进行直观展示:

(图片1)

(图表2)

案例说明

纺织品缩水现象及其应对措施

某纺织厂在生产过程中遇到纺织品缩水问题,具体表现为纤维收缩不均匀,针对这种情况,该厂采取了以下应对措施:

(案例一说明)

- 纤维材质差异控制:严格控制原材料的纤维材质,确保纤维在加工过程中的均匀分布。

- 加工条件优化:调整加工工艺,优化温度、湿度等条件,减少机械、化学等因素对纤维的影响。

- 定期检测与维护:定期对设备进行检测和维护,确保设备正常运行,减少因设备故障导致的缩水问题。

纺织品缩水问题的预防与改善措施

为了预防纺织品缩水问题,该纺织厂采取了以下预防措施:

(预防措施说明)

- 选用优质原材料:选用符合标准要求的原材料,减少纤维材质差异导致的缩水问题。

- 严格控制加工过程:在加工过程中严格控制温度、湿度等条件,确保纤维在加工过程中的均匀分布。

- 加强设备维护:定期对设备进行维护和保养,确保设备正常运行。

缩水原理与案例分析总结

纺织品缩水现象主要是由于纤维受到机械、化学或热力等因素的影响,导致纤维变形或收缩,针对这种情况,纺织厂需要采取相应的应对措施,包括严格控制原材料、优化加工条件、加强设备维护等,为了预防纺织品缩水问题,纺织厂还需要从源头抓起,选用优质原材料,严格控制加工过程,还可以通过定期检测与维护设备等方式,确保纺织品加工过程中的稳定性和一致性。

纺织品缩水问题是纺织生产中常见的问题,通过了解缩水原理和采取相应的应对措施,可以有效地解决缩水问题,纺织厂还需要从源头抓起,严格控制原材料和加工过程,确保纺织品的质量和稳定性,对于已经出现的缩水问题,纺织厂还需要采取有效的预防措施,避免再次发生。

Articles related to the knowledge points of this article:

Understanding the Super Symbols of Textiles:A Comprehensive Guide

The Ultimate Guide to Purchasing Textiles in Beijing

Understanding the Differences between Textile Industry and Textile Products