The Role of Protective Facilities in Textile Mills

Protective facilities in textile mills are crucial for maintaining the quality and safety of the products. These facilities include dust extraction systems, exhaust fans, and air purifiers, which help to reduce the levels of dust, fumes, and other pollutants in the workplace. Additionally, they provide a safe environment for workers to perform their tasks without risking health issues such as respiratory problems. The effectiveness of these protective facilities is often measured by the levels of pollutants in the air and the absence of any health complaints from employees. In order to ensure that these facilities are functioning properly, regular inspections and maintenance are necessary. Failure to maintain these facilities can result in increased health risks for employees and ultimately damage to the reputation of the company. Therefore, it is important that companies invest in the proper maintenance and upkeep of these facilities to protect both their employees and customers.

In the world of textile manufacturing, safety is paramount. From the cutting-edge machinery to the intricate weaving process, every step must be executed with utmost care and precision. This is where protective facilities come into play, ensuring that workers are safeguarded from potential hazards and maintaining a healthy work environment for everyone involved. In this article, we will explore the importance of protective facilities in textile mills and how they can contribute to a safer, more efficient production process.

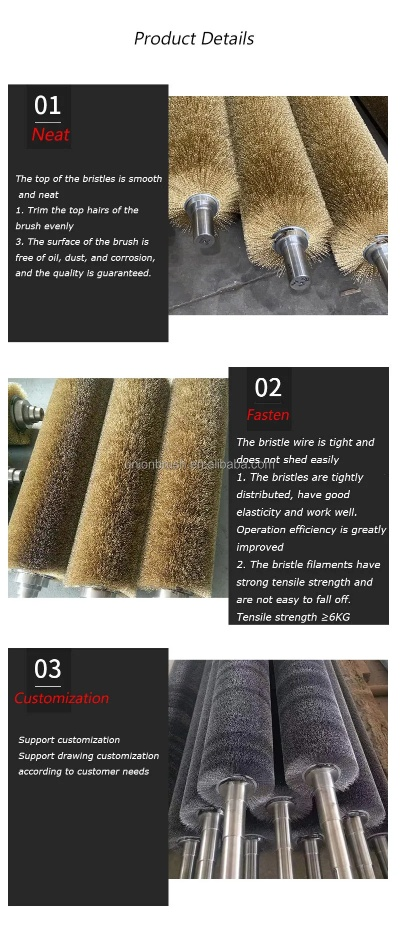

Protective Equipment and Materials

At the heart of any protective facility lies the use of specialized equipment and materials that cater to the unique challenges faced by textile workers. For example, the use of gloves made from flame-resistant materials is essential in preventing burns from hot machinery. Similarly, the use of safety glasses helps prevent eye injuries from flying debris or sharp objects.

In addition to these personal protective devices (PPE), there are also various types of protective materials used in textile mills. These include non-toxic dyes and chemicals, which are designed to minimize exposure to harmful substances. Other materials used include fireproof clothing, noise-cancelling headphones, and anti-static mats, all of which contribute to a safer working environment.

Safety Training and Education

Safety training and education are crucial components of any protective facility. Workers should be educated on the proper use of PPE and other safety equipment, as well as the importance of following safety protocols. By providing regular training sessions, employers can ensure that workers are aware of potential hazards and have the skills necessary to react quickly in case of an emergency.

In addition to individual training, companies should also provide ongoing education for their entire workforce. This could include seminars on new technologies, changes in regulations, or best practices for reducing workplace accidents. By staying up-to-date on industry trends and best practices, workers can help ensure that their workplace remains safe and secure.

Emergency Response Plans

Emergency response plans are another critical aspect of protective facilities in textile mills. These plans outline procedures for dealing with emergencies such as fires, chemical spills, or machinery failures. By having clear protocols in place, employers can minimize the risk of accidents and ensure that workers are prepared to handle any situation that may arise.

For example, many textile mills have established emergency response teams that are trained to handle specific types of emergencies. These teams may include firefighters, medical personnel, and technical experts who can quickly assess the situation and take appropriate action. By having a comprehensive plan in place, employers can ensure that workers are not left in the dark when it comes to emergency response.

Case Study: A Successful Implementation of Protective Facilities

One company that has successfully implemented protective facilities in their textile mill is XYZ Textiles. XYZ Textiles has been investing heavily in safety measures since its inception, and their commitment to protecting workers has led to a significant reduction in workplace accidents.

To start, XYZ Textiles has invested in high-quality PPE, including flame-resistant gloves and safety glasses. They also provide regular training sessions for all employees, covering everything from basic safety procedures to advanced techniques for handling hazardous materials.

In addition to these personal protection measures, XYZ Textiles has also implemented several safety protocols. For example, they have established a comprehensive emergency response plan that outlines procedures for dealing with various types of emergencies. They also have a dedicated team of technical experts who can quickly assess the situation and take appropriate action.

The results of XYZ Textiles' commitment to safety have been nothing short of remarkable. According to recent statistics, the company has seen a significant reduction in workplace accidents over the past year. This includes a decrease in injuries from heat sources, chemical spills, and machinery failures.

Conclusion

In conclusion, protective facilities are essential components of any textile mill's operation. From the use of specialized equipment and materials to regular training sessions and emergency response plans, employers must take proactive steps to ensure that workers are protected from potential hazards. By doing so, they can create a safer, more productive work environment for everyone involved.

随着工业化的快速发展,纺织厂作为重要的工业生产基地,其安全生产和防护设施的建设显得尤为重要,本文将围绕纺织厂防护设施为主题,从多个方面进行深入探讨。

纺织厂防护设施概述

纺织厂防护设施主要包括防尘、防毒、防噪声、防震等各类防护措施,这些设施的设计和建设直接关系到员工的人身安全和企业的生产效率。

防护设施的类型与作用

- 防尘设施:包括防尘网、除尘设备等,用于减少和防止粉尘的产生和扩散。

- 防毒设施:包括防毒面具、隔离设施等,用于防止有毒气体和粉尘的侵入。

- 防护噪声设施:包括隔音设备、降噪材料等,用于降低生产过程中的噪声污染。

- 防护震设施:包括抗震支架、抗震墙等,用于应对地震等自然灾害对生产场所造成的破坏。

防护设施的实例分析

以下是一个具体的防护设施实例分析,以供参考:

某纺织厂在建设过程中,充分考虑了员工的安全和生产效率,采取了以下防护措施:

- 防尘设施:采用了高效能的防尘网和专业的除尘设备,有效减少了粉尘的产生和扩散,工厂还配备了自动清洁系统,定期对设备进行清洗和维护,确保设备的正常运行。

- 防毒设施:工厂配备了专业的防毒面具和隔离设施,确保有毒气体不会对员工造成伤害,工厂还建立了应急救援预案,以便在出现有毒气体泄漏等情况时能够迅速应对。

- 防护噪声设施:工厂采用了隔音设备和技术,有效降低了生产过程中的噪声污染,工厂还定期对员工进行噪声防护培训,提高员工的噪声防护意识。

防护设施的改进与优化建议

- 加强设计:在建设防护设施时,应注重科学设计,确保设施的安全性和可靠性,应充分考虑生产过程中的实际情况,确保设施能够适应生产需求。

- 定期检查和维护:应定期对防护设施进行检查和维护,确保设施的正常运行,应建立完善的维护制度,确保设施能够得到及时修复和更新。

- 提高员工安全意识:应加强员工的安全培训和教育,提高员工的防护意识和技能水平,应建立完善的应急预案和救援体系,以便在出现安全事故时能够迅速应对。

纺织厂防护设施的建设对于保障员工的人身安全和企业的生产效率具有重要意义,在建设过程中,应注重科学设计、定期检查和维护、提高员工安全意识等方面的工作,还应不断探索和创新防护设施的建设和管理方式,以适应工业化的快速发展和市场需求的变化。

Articles related to the knowledge points of this article:

The Efficient Operation of Textile Factory Water Shroud Fan System

Transforming the Industry:The Story of Gaomi Zhengda Textile Factory