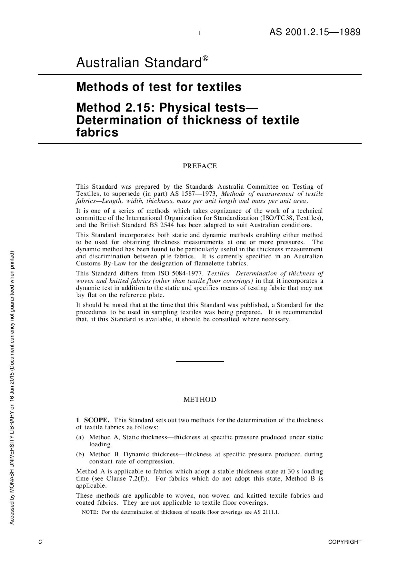

The Essential Steps in Textile Physical Testing

: The Essential Steps in Textile Physical Testing,Textile physical testing is a crucial aspect of the fabrication process, as it ensures the quality and functionality of finished products. This paper outlines the essential steps involved in textile physical testing, focusing on the mechanical properties such as strength, flexibility, and durability.,Firstly, the selection of appropriate testing equipment and methods is critical for accurate results. Different tests may require different types of instruments, and choosing the right one is essential to obtain reliable data.,Secondly, pre-testing of raw materials is necessary to understand their inherent characteristics before they are subjected to further processing. This helps in predicting the performance of the final product.,Thirdly, sample preparation is vital in ensuring consistent and repeatable results. Proper handling, cutting, and labeling of samples are essential steps that must be followed strictly.,Fourthly, the actual testing procedure is conducted, which involves subjecting samples to various stresses and strains to measure their resistance to wear and tear, tear strength, elongation, and hardness.,Finally, post-testing analysis is essential to evaluate the outcomes and identify any issues or defects in the tested samples. Post-testing analysis includes measuring the dimensions of the samples and calculating their weight to determine their density.,In conclusion, textile physical testing is an essential step in ensuring the quality and functionality of finished products. By following these essential steps, manufacturers can produce high-quality textile products that meet the demands of the market.

Introduction: Textile materials are critical components of our daily lives, from clothing to bedding to industrial textiles. To ensure their quality and durability, it is essential to perform rigorous physical testing. In this guide, we will discuss the key steps involved in performing textile physical tests, along with a table that outlines common test parameters. By understanding these steps, textile professionals can ensure that their products meet industry standards and consumer expectations.

Sample Preparation: The first step in any physical testing process is preparing the sample. This involves selecting appropriate samples, ensuring they are free from contaminants, and measuring their dimensions. Here is an example table showing common sample preparation parameters:

| Sample Type | Dimensions (cm) | Contaminant Removal |

|---|---|---|

| Cotton Tissue | 20 x 20 | No |

| Wool Blend | 50 x 50 | Yes |

| Polyester Fabric | 40 x 40 | Yes |

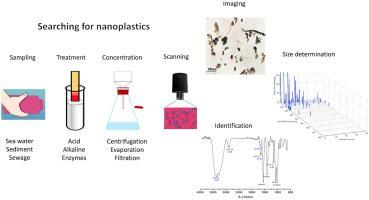

Instrumentation: To measure properties such as strength, elongation, and tear resistance, specialized instruments are required. Common instruments used in textile testing include:

| Instrument | Function |

|---|---|

| Tensile Tester | Determines material's breaking strength |

| Elongometer | Measures material's elongation at break |

| Stretch Tester | Analyzes material's elongation under tension |

| Tear Tester | Assesses material's tear strength |

Test Procedures: Each test requires specific procedures. For example, in a tensile test, the sample is placed in a clamping device and subjected to a pulling force until failure occurs. The maximum load at which the sample breaks is recorded as the breaking strength. Here's how a typical tensile test might look:

| Test Type | Preparation | Procedure |

|---|---|---|

| Tensile Test | Pre-conditioned sample, clamped, applied load, record maximum load | Load applied until failure; measure and record maximum load |

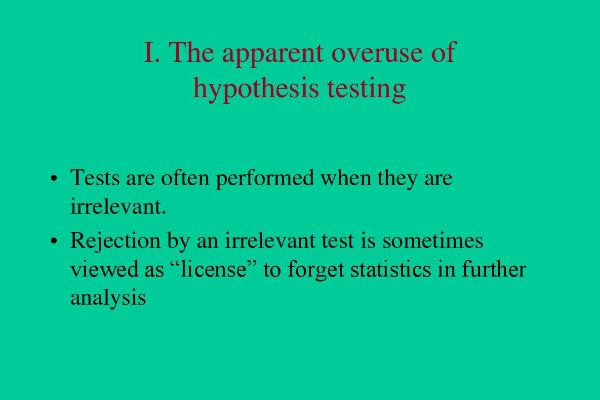

Data Analysis: Once the test is completed, data analysis is crucial for interpreting the results. This typically involves comparing the measured values to established standards or industry norms. Here's an example table showcasing common data analysis steps:

| Test Type | Parameters | Analysis |

|---|---|---|

| Tensile Test | Breaking strength (MPa) | Compared to ASTM D638 standards |

| Elongation Test | Elongation (%) | Compared to ASTM D3872 standards |

| Tear Test | Tear strength (N/m) | Compared to ASTM D624 standards |

Example Case Study: Let's say a textile manufacturer is developing a new fabric for outdoor apparel. They need to ensure its strength and resistance to wear. They select a polyester blend sample and prepare it following the guidelines provided in Table 1. Using a tensile tester, they apply a constant force of 100 N until the sample breaks. The maximum load recorded as 30 MPa meets the standard set by ASTM D638. However, the manufacturer notices that the fabric also has a high elongation of 3%. They decide to further analyze this property using an elongometer, finding out that the fabric's elongation at break reaches up to 12%, which exceeds the recommended limit. The manufacturer adjusts their design to reduce the elongation and improve overall wear resistance without compromising on comfort.

Conclusion: Textile physical testing is a crucial step in ensuring product quality and meeting industry standards. By following the outlined steps with precision, textile professionals can effectively evaluate and optimize their products. Remember, every detail counts when it comes to delivering a durable and reliable textile solution to consumers.

在纺织品生产过程中,物理测试是确保产品质量的重要环节,本文将详细介绍纺织品物理测试的步骤,并通过案例说明来加深理解。

纺织品物理测试步骤

材料准备

a. 选择合适的测试样品,确保样品具有代表性。 b. 对样品进行预处理,如清洗、干燥等。

仪器选择与准备

a. 选择合适的物理测试仪器,如温度计、压力计、扫描电子显微镜等。 b. 对仪器进行校准或预热,确保测试结果的准确性。

测试方法与流程

a. 根据测试需求,选择合适的测试方法,如拉伸性能测试、耐磨性测试等。 b. 按照测试流程进行操作,包括样品固定、环境控制、数据采集等。

数据采集与处理

a. 使用仪器记录样品在不同条件下的数据,如温度、压力、形变等。 b. 对数据进行处理和分析,得出测试结果。

结果评估与报告

a. 根据测试结果评估样品的质量和性能。 b. 撰写测试报告,包括样品基本信息、测试方法、结果分析等。

案例说明

以纺织品耐磨性测试为例,详细说明纺织品物理测试步骤:

- 材料准备:选择耐磨性测试样品,确保样品具有代表性,清洗样品表面,去除杂质和油脂。

- 仪器选择与准备:选择合适的耐磨性测试仪器,如摩擦系数测量仪、磨损机等,对仪器进行校准或预热,确保测试结果的准确性。

- 测试方法与流程:根据耐磨性测试需求,选择合适的测试方法,如摩擦系数测量法,将样品放置在摩擦系数测量仪上,设定合适的摩擦速度和时间,进行耐磨性测试,记录样品在不同条件下的数据,如温度、压力等,对数据进行处理和分析,得出耐磨性测试结果。

- 结果评估与报告:根据测试结果评估样品的质量和性能,如果样品表现出良好的耐磨性,可以将其标记为合格产品;如果需要改进产品性能,可以提出相应的改进措施和建议,撰写测试报告,包括样品基本信息、耐磨性测试方法、结果分析等,报告中应详细说明样品的特点、性能指标以及改进措施和建议。

纺织品物理测试是确保纺织品产品质量的重要环节,通过选择合适的测试仪器和测试方法,并按照正确的步骤进行操作,可以得出准确的测试结果,通过案例说明可以加深对纺织品物理测试的理解和掌握,在实际生产过程中,应该严格按照测试步骤进行操作,以确保产品的质量和性能符合要求。

Articles related to the knowledge points of this article:

Navigating the World of Textile Dyes and Fixatives for Success

The Price Dynamics of Lavender Textile Products:A Comprehensive Look

The Art of Salt-Grain Textiles:Crafting a Luxury Fabric

Top Ten Textile Brands in the World:Brands,Prices and Visual Evidence