The Evolution of Textile Manufacturing:A Global Perspective

: The Evolution of Textile Manufacturing: A Global Perspective,In the past century, textile manufacturing has undergone a remarkable transformation. From the traditional looms and weaving techniques to the latest digital innovations, the industry has evolved to meet global demand and technological advancements. This paper aims to explore the historical development of textile manufacturing and analyze how it has been shaped by global factors such as economic growth, technological advancements, and changes in consumer preferences.,The early stages of textile manufacturing relied heavily on manual labor and traditional methods such as hand spinning and simple knitting. However, with the Industrial Revolution, factories were introduced in Europe and North America, leading to significant improvements in production efficiency and quality. The development of synthetic fibers, such as polyester and nylon, further revolutionized textile manufacturing, making it more cost-effective and versatile than natural fibers.,In recent years, the rise of e-commerce and digital technologies has transformed the industry further. Online marketplaces have enabled consumers to access an array of high-quality, low-cost products from around the world. Additionally, advances in automation and robotics have increased production capacity and reduced labor costs.,Looking towards the future, there is great potential for continued growth in textile manufacturing. As demand for sustainable, eco-friendly materials grows, so too will innovations in biodegradable fibers, recycled materials, and green dyes. Furthermore, advancements in technology such as artificial intelligence and machine learning will play a crucial role in improving productivity and reducing waste.,In conclusion, the evolution of textile manufacturing has been influenced by a range of global factors, including economic conditions, technological advancements, and changing consumer needs. As the industry continues to evolve, it remains essential to stay ahead of trends and adapt to new challenges to ensure its continued success and relevance in the global marketplace.

Introduction Textile manufacturing has been an integral part of human civilization for centuries. From the humble loom to the sophisticated factories, this industry has undergone significant changes over time. In recent years, the global textile industry has experienced a resurgence, driven by advancements in technology and changing consumer preferences. This essay will explore the evolution of textile manufacturing, highlighting some of its key trends and innovations.

The Traditional Processes and Techniques Before the industrial revolution, textiles were primarily hand-woven or spun on simple looms. The process involved weaving or spinning fibers into fabric using a series of wooden or metal looms. This method was labor-intensive and limited the production of high-quality textiles. However, it provided a basic level of consistency and uniformity that helped to create staple garments like shirts, pants, and dresses.

Industrial Revolution With the advent of the industrial revolution, textile manufacturing underwent a dramatic transformation. The introduction of power looms, steam power, and other mechanical devices made the process more efficient and scalable. Textile mills became commonplace, allowing for the mass production of clothing, bedding, and other textile products. This led to a rise in consumer demand for affordable, stylish clothing. The growth of factories also spurred the development of new materials, such as cotton, wool, silk, and synthetic fibers.

Modern Technologies Today's textile manufacturing is powered by advanced technologies such as computer-aided design (CAD), robotics, and automation. These techniques enable manufacturers to produce intricate designs, reduce production times, and improve quality control. For example, 3D printing technology can be used to create customized textile patterns that require no traditional embroidery or sewing. Additionally, machine-washable fabrics are becoming increasingly popular as consumers seek convenience and sustainability.

Sustainability and Ethical Practices As the world becomes more aware of climate change and environmental concerns, sustainable practices have become increasingly important in textile manufacturing. Many manufacturers are adopting eco-friendly materials and processes such as organic farming, recycled polyester, and biodegradable fibers. Moreover, ethical labor practices are gaining traction, with companies committing to fair trade and worker rights. By reducing waste and minimizing harm to the environment, these practices not only help to protect the planet but also enhance the brand's reputation and customer loyalty.

Case Study: Nike - Redefining Sustainability in Sportswear Nike, a leading global sportswear brand, has been at the forefront of sustainability initiatives in the textile industry. Since launching their "Made to Play" program in 2017, the company has partnered with suppliers who adhere to strict environmental and social standards. This initiative has resulted in reduced energy use and water consumption during production, improved working conditions for workers, and increased transparency in supply chain management. Nike's commitment to sustainability extends beyond just reducing its carbon footprint; the brand is also investing in research and development of innovative materials and technologies that promote health and performance. By embracing sustainable practices and prioritizing ethical labor, Nike is setting a new standard for how textile manufacturers should operate.

Conclusion The textile industry has come a long way since the days of hand-woven fabrics. Today, it is a dynamic and ever-evolving sector that continues to push the boundaries of creativity and innovation. As technology advances and consumer demands shift, textile manufacturers must adapt their strategies to meet these challenges head-on. By embracing new technologies, prioritizing sustainability and ethical practices, and staying attuned to changing consumer behaviors, manufacturers can continue to thrive in a rapidly changing marketplace.

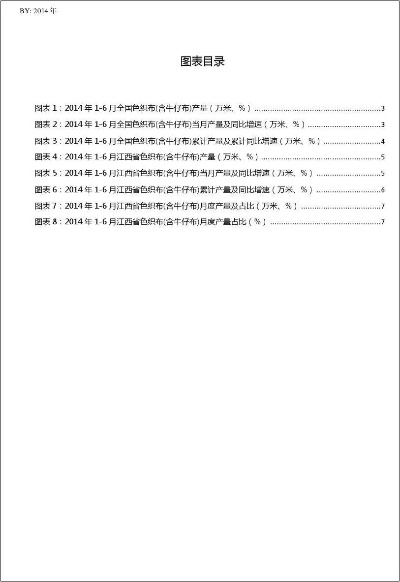

流行纺织品加工概述

随着时尚潮流的不断演变,纺织品加工行业也日益受到关注,流行纺织品加工涵盖了从原材料选择、生产设备、工艺流程到最终产品展示等多个环节,本文将详细介绍流行纺织品加工的相关知识,并结合实际案例进行分析。

流行纺织品加工的主要环节

原材料选择

在流行纺织品加工中,原材料的选择至关重要,需要了解不同材质的特性,如纤维类型、颜色、厚度等,根据市场需求和消费者喜好,选择适合的原材料,天然纤维如棉、麻、丝等因其舒适度、透气性和环保性受到广泛青睐,合成纤维如涤纶、聚酯等因其耐用性和多样性也备受青睐。

生产设备

生产设备是纺织品加工的关键因素之一,现代纺织生产线通常采用自动化、智能化技术,以提高生产效率和产品质量,高速织布机、染整设备、印花设备等都是常见的生产设备,一些先进的设备如智能机器人、3D打印技术等也在纺织品加工中得到了广泛应用。

工艺流程

工艺流程是纺织品加工的核心环节,根据不同的材质和产品需求,采用不同的工艺流程,对于棉质面料,可以采用湿法织造工艺;对于丝绸面料,可以采用干法织造工艺,还需要考虑材料的处理方式、染整工艺、印花工艺等。

流行纺织品加工的实际案例分析

某知名品牌流行纺织品加工

该品牌在流行纺织品加工方面有着丰富的经验和技术积累,他们采用先进的生产设备和技术,从原材料选择到最终产品展示都体现了高度的专业性和创新性,他们使用天然纤维如亚麻和竹纤维制作夏季服装,既环保又舒适;他们采用先进的染整工艺和印花技术,使服装色彩鲜艳、图案精美,该品牌还注重产品的个性化定制和品质控制,以满足不同消费者的需求。

绿色纺织品的创新应用

近年来,绿色纺织品成为时尚界的热点话题,一些品牌开始采用环保材料和生产工艺制作纺织品,以符合可持续发展的要求,某环保纺织品的生产厂家采用了生物降解材料制作衣物,不仅环保还具有时尚感,他们还采用了智能化的生产设备和工艺流程,以提高生产效率和产品质量,这些创新技术的应用不仅提高了纺织品的环保性、舒适性和美观性,也提高了纺织品的附加值和市场竞争力。

流行纺织品加工的发展趋势

随着科技的不断进步和消费者需求的不断变化,流行纺织品加工的发展趋势也在不断变化,纺织品加工将更加注重环保、可持续性和个性化定制,一些新技术和新材料也将被广泛应用于纺织品加工中,如3D打印技术、纳米技术等,智能化和自动化也将成为纺织品加工的重要趋势,以提高生产效率和产品质量。

流行纺织品加工是一个涉及多个环节的行业,在追求时尚的同时,我们也应该注重环保和可持续性,通过不断的技术创新和工艺改进,我们相信纺织品加工行业将会更加繁荣和发展。

Articles related to the knowledge points of this article:

The Dynamics of Jinlan Textiles:An Industry Leader in Global Apparel Market

The Benefits of Textile Humidification:A Comprehensive Guide