Textile Burning Test Methodology

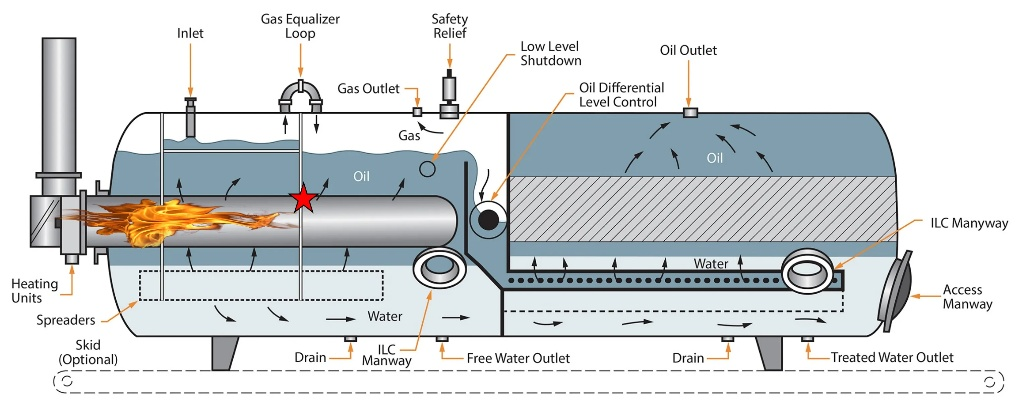

In the field of textile testing, there is a crucial method known as the textile burning test methodology. This method is utilized to assess the resistance of fabrics to flame exposure. The objective of this test is to evaluate how well a fabric can withstand high temperatures and resist burning.,The process involves immersing the fabric in an oven or furnace heated to a specific temperature, typically around 600°C. During this process, the fabric is exposed to intense heat, causing it to burn and char. The extent of the burn is measured using a scaled measurement system, which rates the severity of the damage based on various parameters such as color loss, material melting, and charring.,This test method is critical for determining the fire resistance properties of textile materials. It provides valuable insights into the performance of different fabrics in real-world applications, including clothing, carpets, and upholstery. By evaluating the results obtained from the textile burning test, manufacturers can make informed decisions about the materials they use in their products, ensuring that they meet the necessary standards and regulations regarding fire safety.

Introduction: The textile burning test method is used extensively in various industries, including the textile and apparel sectors, to evaluate the level of flame resistance of materials. It serves as a critical assessment tool for determining the potential risk of fire during manufacturing, storage, or use. This method is essential for ensuring that products are safe to handle and reduce the risk of accidents. In this article, we will discuss the textile burning test methodology, including its components, standards, and practical applications.

Components of the Textile Burning Test: The textile burning test involves several components, each aimed at assessing different aspects of fabric's fire-resistant properties. These components include the following:

-

Sample Preparation The sample preparation step involves selecting an appropriate piece of fabric to be tested. The sample should represent typical conditions of use and have a consistent thickness and weight. The sample must also be free from impurities that could influence the results.

-

Flame Source A standardized flame source is used to generate a controlled fire. The flame source must be capable of producing high-intensity flames with a stable burn rate, which helps in accurately measuring the material's resistance to heat and smoke.

-

Thermocouple A thermocouple is used to measure the temperature at different points on the fabric during the burning process. The temperature measurement helps to determine how well the fabric can resist the intense heat generated during the burning process.

-

Smoke Generator Smoke generation is crucial for evaluating the extent of damage caused by the flame. A smoke generator is used to produce smoke particles that adhere to the fabric's surface. The amount and type of smoke produced are measured to assess the fabric's ability to protect against smoke inhalation and fire spread.

-

Data Recording The data recorded during the test includes measurements of the flame height, temperature, smoke concentration, and any other relevant parameters. These data are then analyzed to determine the fabric's flame resistance performance.

Standards for the Textile Burning Test: Several international and national standards exist for defining and implementing the textile burning test methodology. For example, the International Organization for Standardization (ISO) has established the ISO 18760 series of standards for textiles and apparel testing, which includes a comprehensive set of requirements for flame retardancy testing. Other standards, such as ASTM D6429, provide guidance on conducting similar tests.

Practical Applications of the Textile Burning Test: The textile burning test is widely used in the textile industry, where it is used to ensure that products meet safety and performance requirements. Some practical applications include:

-

Product Development Textile designers and manufacturers use the test to assess the fire resistance properties of new fabric samples before they are released into the market. This ensures that products comply with regulatory requirements and minimize the risk of accidents during use.

-

Quality Control Quality control personnel can use the test to verify that products meet the required standards for fire resistance. This helps to identify and address any issues with fabric quality and ensure that products are safe for consumers.

-

End-User Testing In some cases, end-users may require a certification from a third-party testing laboratory that verifies the product's fire resistance capabilities. The textile burning test can be used to satisfy this requirement and demonstrate compliance with relevant regulations and standards.

-

Regulatory Compliance Companies need to comply with various regulations and standards related to fire safety, such as the Consumer Product Safety Commission (CPSC) and Occupational Safety and Health Administration (OSHA). The textile burning test provides one of the key methods for demonstrating compliance with these regulations.

Case Study: Consider the case of a fashion brand that produces high-end clothing for women's wear. The brand wanted to ensure that their garments met strict fire resistance requirements, especially during extreme weather events like hurricanes or wildfires. To achieve this, the company conducted a series of textile burning tests using the standard ISO 18760-1 method. They selected a variety of fabrics, including synthetic and natural materials, and evaluated their flame resistance properties under controlled conditions. The results showed that all the fabrics had excellent fire resistance, meeting the brand's requirements for safety during high-risk situations. As a result, the brand was able to confidently launch their garments, knowing that they were compliant with all relevant regulations and standards.

Conclusion: The textile burning test is an indispensable tool for assessing the fire resistance properties of textile materials. By following standardized procedures and incorporating relevant data analysis techniques, companies can effectively evaluate and improve their products' safety and performance characteristics in real-world scenarios. In conclusion, the textile burning test plays a vital role in ensuring consumer safety, protecting property, and adhering to legal regulations.

在日常生活中,纺织品是我们日常生活中不可或缺的一部分,为了确保纺织品在使用过程中的安全性和可靠性,我们常常采用纺织品燃烧实验法来进行检测,本篇将通过详细的实验过程和案例分析,为大家介绍纺织品燃烧实验法的相关知识。

纺织品燃烧实验法简介

纺织品燃烧实验法是一种通过观察和测试纺织品在特定条件下燃烧行为的方法,以评估其燃烧性能和安全性,该方法主要包括以下几个步骤:准备样品、点燃样品、观察并记录燃烧过程、分析燃烧产物等。

实验步骤

- 准备样品:选择具有代表性的纺织品样品,确保样品具有足够的燃烧性能和安全性。

- 点燃样品:使用适当的点火设备点燃样品,观察并记录燃烧过程。

- 分析燃烧产物:观察并记录燃烧过程中产生的烟雾、火焰、气味等,分析燃烧产物的成分和性质。

- 数据记录:详细记录实验过程中的数据,包括样品类型、燃烧温度、燃烧时间等。

案例说明

某品牌纯棉T恤的燃烧实验

某品牌纯棉T恤是我们此次实验的对象,我们准备了该品牌的纯棉T恤样品,确保其具有足够的燃烧性能和安全性,我们使用适当的点火设备点燃样品,观察并记录了燃烧过程,在燃烧过程中,我们发现该品牌的纯棉T恤产生的烟雾较为均匀,火焰较为稳定,没有产生有害气体和烟尘,我们还分析了燃烧产物的成分和性质,发现其主要成分是纤维素和少量的其他化学物质。

纺织品燃烧实验中的安全注意事项

在进行纺织品燃烧实验时,我们需要注意以下几点安全事项:确保实验环境通风良好,避免烟雾和有害气体对实验人员的伤害;使用适当的点火设备进行点火,避免使用明火或易燃物品进行点火;在观察并记录实验过程中,注意保护个人安全和实验数据的安全保密。

实验结果分析

根据实验数据记录和分析,我们可以得出以下结论:该品牌的纯棉T恤在燃烧过程中表现出良好的燃烧性能和安全性,产生的烟雾和火焰较为均匀,没有产生有害气体和烟尘,我们还发现该品牌的纯棉T恤的主要成分是纤维素,符合纺织品的常规性能指标。

纺织品燃烧实验法是一种有效的检测纺织品燃烧性能和安全性的方法,通过该方法,我们可以评估纺织品的燃烧性能和安全性,确保其在使用过程中的安全性和可靠性,我们还需要注意实验过程中的安全事项,避免对实验人员和环境造成伤害。

Articles related to the knowledge points of this article:

Leading the Way in Textiles:The Story of Lidu Fabric Factory