纺织品检验检测运营,确保质量与合规性的关键

The operation of textile testing and inspection is crucial for ensuring quality and compliance. This process involves the use of advanced technology and expertise to evaluate the performance and safety of textile products, such as clothing, bedding, and furnishings. The testing methods used in this industry are diverse and include various techniques, such as visual inspection, mechanical testing, and chemical analysis. These tests help identify any defects or flaws in the fabrics, which can affect their performance and durability. Additionally, the testing process also helps to ensure that textile products meet regulatory standards and comply with international regulations. By conducting regular inspections and testing, manufacturers can prevent issues from arising and maintain their reputation for producing high-quality products. Overall, the operation of textile testing and inspection is essential for ensuring that textile products meet the needs of consumers and contribute to the overall well-being of society.

Introduction: In the globalized world of fashion and textiles, ensuring product quality and conformity to regulations is crucial for businesses. Textile products are not just functional but also a reflection of a brand's reputation and consumer trust. This presentation will discuss how textile companies can effectively manage their textile products through a comprehensive range of testing processes and strategies.

-

Quality Control in Textile Production

- Raw Material Inspection: The first step in quality control is to ensure that the raw materials used in the production process meet industry standards. Companies should regularly inspect suppliers' certifications and conduct tests on their own raw materials to guarantee consistency in quality.

- Process Control: During the manufacturing phase, various parameters such as temperature, humidity, and pressure must be precisely controlled to prevent defects. Advanced technology like automated monitoring systems can help maintain consistent quality across different stages of production.

- Quality Assurance (QA) Team: A dedicated QA team is essential for monitoring and controlling the entire production process. They should be responsible for identifying potential quality issues early on and implementing corrective actions.

-

Sample Testing and Analysis

- Standard Testing: Standard testing methods like ASTM, ISO, and JIS are widely accepted and provide a reliable basis for assessing the quality of textile products. These tests cover various aspects like colorfastness, tear strength, and shrinkage.

- Customized Testing: For specific applications or markets, customized testing may be necessary. Companies should collaborate with testing laboratories to develop appropriate test protocols that cater to their needs.

- Data Analysis: Collected data from sample tests should be analyzed thoroughly to identify trends and patterns that might affect the overall quality of the products. This information can then be used to optimize production processes.

-

End-of-Life Product Inspections

- Recycled Products: Many textiles are made from recycled materials. It is critical to ensure that these recycled products meet the same quality standards as their new counterparts. Regular inspections and testing are necessary to maintain product integrity.

- Disposal Products: When textiles reach the end of their life cycle, they should be disposed of properly to avoid environmental pollution. Companies should have established recycling programs and disposal guidelines to minimize harm to the environment.

-

Regulatory Compliance

- International Regulations: Companies need to comply with international regulations like OEKO-TEX Standard 100 and REACH to ensure the safety and health of consumers. These regulations require regular audits and testing to maintain compliance.

- Local Laws and Policies: Local laws and policies can also impact textile products' quality and safety. Companies need to stay informed about any changes and ensure that their products comply with local regulations.

-

Technology and Innovation

- Advanced Testing Equipment: Advances in testing equipment have led to more accurate and efficient testing methods. Companies should invest in state-of-the-art testing facilities to enhance the quality control process.

- Digital Transformation: Digital technologies like AI and machine learning can be used to automate testing processes, improve accuracy, and reduce human error. Companies should explore ways to integrate these technologies into their testing workflows.

-

Customer Feedback and Continuous Improvement

- Feedback Collection: Providing customers with easy access to feedback forms or channels can help identify areas for improvement. Companies should analyze customer feedback regularly to understand their needs better.

- Continuous Learning: Companies should continuously learn from both internal and external sources to stay updated with the latest trends and best practices in textile quality control.

-

Role of Quality Management Systems (QMS)

- QMS Implementation: Implementing a robust QMS can help companies standardize their quality control processes, track performance, and identify areas for improvement.

- Training and Education: Ensuring all employees are trained in QMS principles and procedures is crucial for maintaining high-quality products. Companies should regularly update their training programs to keep up with changing requirements.

-

Conclusion In conclusion, textile companies must adopt a comprehensive approach to quality control by integrating various testing processes, establishing effective QA teams, and staying informed about regulatory compliance. By leveraging technology and continually improving their processes, companies can deliver high-quality products that meet the expectations of their customers and stakeholders alike.

随着纺织行业的快速发展,纺织品检验检测运营的重要性日益凸显,本篇文章将围绕纺织品检验检测运营的主题,从多个角度展开讨论,并提供相关英文案例说明。

纺织品检验检测运营概述

纺织品检验检测的定义与重要性

纺织品检验检测是确保纺织品质量的重要手段,它涉及到对纺织品原材料、生产过程、成品的质量控制,通过纺织品检验检测运营,可以确保纺织品符合相关标准和法规要求,提高纺织品的质量和可靠性。

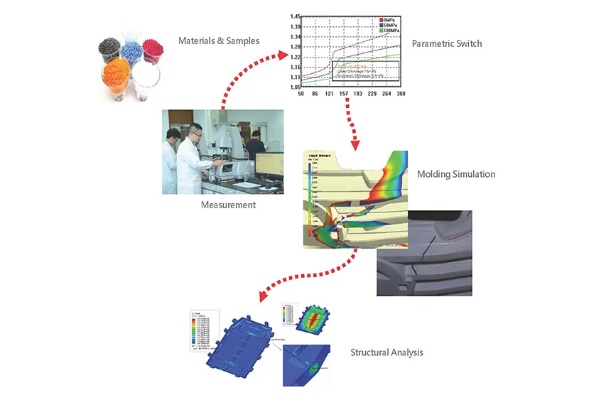

纺织品检验检测运营的流程

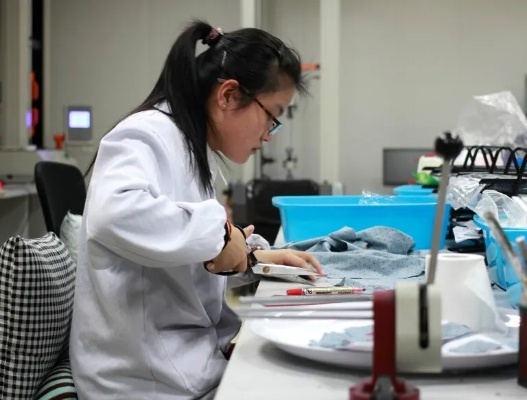

纺织品检验检测运营的流程主要包括样品接收、检验检测、结果反馈和数据处理等环节,在样品接收环节,需要确保样品符合检验检测的要求;在检验检测环节,需要采用先进的检测设备和技术手段,对样品进行准确的检测;在结果反馈环节,需要将检测结果及时反馈给相关方,以便他们了解纺织品的质量情况;在数据处理环节,需要对检测数据进行整理和分析,为后续的决策提供依据。

纺织品检验检测运营案例分析

某纺织企业纺织品检验检测运营案例

某纺织企业是一家大型纺织企业,其纺织品检验检测运营采用了先进的检测设备和技术手段,对纺织品的质量进行了全面的控制,该企业在样品接收环节采用了严格的把关制度,确保样品符合检验检测的要求;在检验检测环节,采用了多种检测方法,包括化学分析、物理性能测试、微生物检测等,对样品进行准确的检测;在结果反馈环节,该企业及时将检测结果反馈给客户和相关部门,以便他们了解纺织品的质量情况;该企业还建立了完善的追溯体系,确保了纺织品的质量可追溯性。

纺织品检验检测新技术应用案例

近年来,纺织品检验检测领域涌现出了一些新技术应用案例,采用智能传感器技术对纺织品进行实时监测,提高了检测的准确性和效率;采用大数据分析技术对检测数据进行整理和分析,为决策提供依据,这些新技术应用案例为纺织品检验检测运营提供了新的思路和方法,有助于提高纺织品的质量和可靠性。

纺织品检验检测运营实践与建议

加强样品管理

加强样品管理是纺织品检验检测运营的重要环节,企业应建立完善的样品管理制度,确保样品来源可靠、质量可控,应采用先进的样品管理技术手段,提高样品管理的效率和准确性。

提升检测技术水平

提升检测技术水平是提高纺织品质量的重要手段,企业应加强技术研发和人才培养,引进先进的检测设备和技术手段,提高检测的准确性和效率,应建立完善的检测标准和质量管理体系,确保检测结果的可靠性和有效性。

加强数据分析和应用

加强数据分析和应用是纺织品检验检测运营的关键环节,企业应建立完善的数据管理系统,对检测数据进行整理和分析,为决策提供依据,应利用数据分析结果,优化生产工艺和质量控制措施,提高纺织品的质量和可靠性。

纺织品检验检测运营是纺织行业发展的重要保障,通过加强样品管理、提升检测技术水平、加强数据分析和应用等措施,可以确保纺织品质量符合相关标准和法规要求,提高纺织品的质量和可靠性,还可以为纺织企业的决策提供依据和支持。

Articles related to the knowledge points of this article:

The Journey of Ethical Textiles 法诗诺纺织品之旅