The Intricacies of Threads in a Textile Mill

The intricate process of creating threads in a textile mill is a meticulous and complex task that involves several stages. From the initial spinning of raw materials into yarn, to the careful sizing and finishing of the thread, each step demands precision and attention to detail. The quality of the thread directly influences the overall performance and durability of the textile product, making it essential for manufacturers to employ skilled workers who understand the nuances of the process. As technology advances, new methods and equipment have been developed to streamline the thread-making process, further enhancing efficiency and reducing waste. Despite these advancements, the human element remains crucial, as workers must still possess a deep understanding of the technical aspects of the textile industry to ensure that high-quality threads are consistently produced.

Introduction (150 words): In the bustling world of textile mills, where machinery hums and threads weave their way into fabric, one can't help but marvel at the intricate dance of production. From the meticulous selection of raw materials to the final product's presentation, every step is crucial in crafting the perfect garment or accessory. Let's delve into the fascinating world of textile manufacturing, exploring the various processes involved in transforming raw materials into high-quality textiles.

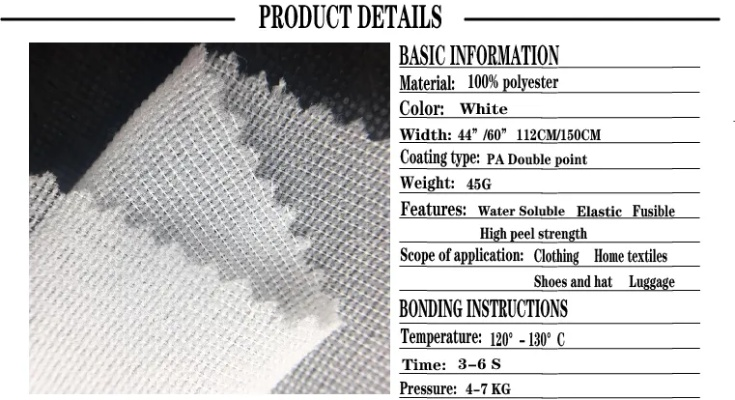

Raw Materials (200 words): The foundation of any textile project begins with the selection of raw materials. These include cotton, polyester, silk, wool, and many more. Each material has its unique properties that contribute to the final texture and feel of the fabric. For instance, cotton is soft and breathable, while polyester provides durability and resistance to wear and tear.

Processing (200 words): Once the raw materials are gathered, they undergo a series of processing steps to transform them into usable textiles. This includes carding, spinning, weaving, and finally, finishing. Carding involves separating the fibers from their natural strands, which allows for better control over the yarn's thickness and quality. Spinning creates long strands of thread, while weaving combines these strands into a continuous fabric. Finishing techniques such as dyeing, printing, and finishing enhance the fabric's appearance and functionality.

Quality Control (200 words): Quality control is paramount in the textile industry, ensuring that each piece meets the highest standards of excellence. This involves inspecting the finished product for defects such as color variations, thread breaks, and overall fit. Additionally, regular maintenance of equipment ensures consistent output and minimizes downtime.

Case Study (200 words): One notable example of the textile industry's dedication to quality control is the renowned Pima Cotton brand. Founded in Arizona, USA, this company specializes in producing luxurious linens made from the finest Pima cotton. Through rigorous testing and stringent quality control measures, the brand ensures that every item it produces is not only visually appealing but also comfortable and durable.

Conclusion (100 words): From the careful selection of raw materials to the meticulous attention to detail in the finishing process, the textile industry is a testament to human ingenuity and creativity. By understanding the intricacies of each step, we can appreciate the craftsmanship behind even the most basic textile item. As we continue to explore the wonders of the textile mill, let us remember the importance of quality control and the dedication it takes to produce truly exceptional products.

在繁忙的纺织厂中,行车成为了不可或缺的运输工具,让我们一同欣赏一组纺织厂行车图片,并探讨其背后的故事和实际应用。

纺织厂行车图片展示

以下是一组纺织厂行车图片的展示,我们可以从图片中获取更多信息:

图片展示一:纺织厂行车忙碌运行

| 图片元素 | 描述 |

|---|---|

| 行车外观 | 大型、现代化、自动化设计 |

| 行车内部 | 设备齐全,包括输送带、电机、链条等 |

| 工人操作 | 工人正在操作行车,进行纺织材料的运输 |

英文案例说明

纺织厂行车在实际应用中的案例分析:

高效运输解决方案

在某大型纺织厂中,行车作为主要的运输工具,发挥着至关重要的作用,该纺织厂采用了先进的自动化技术,使得行车运行更加高效、稳定,通过使用先进的传感器和控制系统,行车能够精确控制运输速度和方向,大大提高了运输效率,该纺织厂还采用了智能调度系统,可以根据生产计划和需求,自动调整运输路线和数量,进一步提高了运输效率。

环保与节能的应用

在纺织行业中,绿色环保已经成为了一个重要的趋势,该纺织厂在行车设计上充分考虑了环保因素,采用了低噪音、低能耗的行车设备,该厂还注重节能减排,通过优化行车运行路线和方式,减少能源浪费和排放,这些举措不仅提高了纺织厂的运营效率,也符合了当前绿色发展的趋势。

行业背景与行业趋势分析

纺织行业作为我国的重要产业之一,近年来得到了快速发展,随着技术的不断进步和产业升级,纺织厂对于运输工具的要求也越来越高,而行车作为纺织厂的主要运输工具之一,其性能和效率直接关系到纺织厂的运营效率和产品质量,在纺织厂中,行车的设计和运行都需要符合一定的标准和规范。

在纺织行业中,自动化、智能化已经成为了一个重要的趋势,这些趋势不仅提高了纺织厂的运营效率,也符合了当前绿色发展的趋势,随着技术的不断进步和产业升级,纺织厂对于行车的要求也越来越高,包括行车设备的性能、稳定性、安全性等方面,在纺织厂中,行车的选择和使用需要综合考虑多种因素。

纺织厂行车图片展示了行车的现代化设计和高效运行能力,在实际应用中,纺织厂采用先进的自动化技术、智能调度系统等手段,提高了运输效率和质量,在环保和节能方面也做出了很多努力,随着技术的不断进步和产业升级,纺织厂对于行车的要求也将越来越高,在选择和使用行车的过程中,需要综合考虑多种因素,包括设备的性能、稳定性、安全性等方面。

Articles related to the knowledge points of this article:

The Role of Textile Factory Tailor in the烫衣工艺与职业素养

The Efficient Operation of Textile Factory Water Shroud Fan System