The Future of Textiles in Japan:Modern Factories and Technological Advances

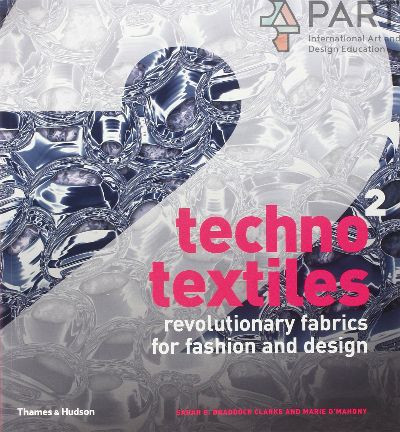

The future of textiles in Japan is poised on the cusp of a technological revolution, with modern factories and advanced technologies set to shape the industry's trajectory. As automation and precision engineering become increasingly prevalent, traditional textile processes are being transformed into streamlined, high-efficiency operations.,Innovative materials are also driving advancements, with new fabrics and finishes emerging that cater to specific needs and preferences. From eco-friendly materials to lightweight, breathable fabrics designed for athletic wear, Japan's textile sector is continually pushing boundaries, creating products that are not only functional but also stylish and sustainable.,As the industry continues to evolve, it is essential to note that innovation is not just about technological advancements; it also involves a deep understanding of consumer behavior and market trends. By staying ahead of the curve and adapting to changing demands, Japan's textile industry stands poised to remain at the forefront of global fashion and design.

Introduction: Japan is renowned for its advanced manufacturing capabilities, particularly in the textile industry. With a focus on sustainability and innovation, Japanese modern textile factories are at the forefront of global textile production. This article will explore the key trends shaping the future of textiles in Japan, including advancements in technology, sustainable practices, and international collaborations. We'll also present an illustrative case study to highlight some of the most innovative textile factories operating today.

Technology Advancements: In recent years, Japanese textile factories have been investing heavily in technological advancements to improve efficiency and reduce waste. One such example is the use of automated weaving machines that can produce high-quality fabrics with minimal human intervention. These machines utilize sensors and algorithms to adjust the weaving process according to the type of yarn being used, ensuring consistency and quality.

Another notable development is the introduction of smart textiles. These are materials designed to interact with electronic devices, providing users with personalized experiences and functionality. For example, smart fabrics can detect changes in temperature or humidity, automatically adjusting their color or texture to provide optimal comfort.

Sustainability Practices: Japanese textile factories are committed to reducing their environmental impact by adopting sustainable practices. One approach is the use of renewable energy sources, such as solar panels or wind turbines, to power their factories. Another method involves using eco-friendly dyes and chemicals, which minimize the release of harmful substances into the environment.

Furthermore, many Japanese textile factories are implementing circular economy models that aim to reuse and recycle materials rather than producing new ones. This practice not only reduces waste but also helps to conserve resources and promote economic growth.

International Collaborations: To stay competitive in the global market, Japanese textile factories are increasingly collaborating with other countries. These partnerships often involve joint research and development projects, where both parties share knowledge and expertise to develop new products and technologies.

For instance, Japanese textile companies have collaborated with French and Italian designers to create unique collections inspired by traditional Japanese craftsmanship. These collaborations not only enhance the aesthetic appeal of their products but also contribute to promoting cross-cultural exchange and understanding.

Case Study: One of the most innovative textile factories in Japan is the Takashimaya Corporation. Founded in 1924, this company has grown into one of the largest textile producers in the world. Takashimaya employs state-of-the-art technology and implements sustainable practices to produce high-quality textiles.

One notable feature of Takashimaya is its commitment to using recycled materials in their production processes. The company has developed a system whereby old clothes are sorted and processed into new textiles, effectively turning waste into value.

Another area where Takashimaya excels is in the use of digital technology. The company has implemented a fully automated supply chain management system that ensures efficient production and reduced waste. Additionally, Takashimaya has partnered with leading fashion brands to create exclusive collections that showcase their latest designs.

Conclusion: The future of textiles in Japan looks bright, driven by technological advancements, sustainable practices, and international collaborations. Japanese modern textile factories are at the forefront of developing new materials, creating innovative designs, and promoting environmental responsibility. As these factories continue to evolve, they will undoubtedly play a crucial role in shaping the future of the global textile industry.

背景介绍

日本作为全球纺织业的重要国家,近年来在纺织技术的创新和产业升级方面取得了显著成就,我们将聚焦一家位于日本现代纺织厂的最新发展和技术应用。

现代纺织厂概述

现代纺织厂位于日本某地区,专注于生产高品质、高附加值的纺织品,该厂采用了先进的生产设备和技术,致力于满足市场对高质量纺织品的需求,该厂还注重环保、可持续性,致力于打造绿色、健康的纺织产业。

主要技术和设备

- 自动化生产系统:现代纺织厂采用了先进的自动化生产系统,包括机器人生产线和智能控制系统,这些系统能够提高生产效率,降低人工成本,同时保证产品质量。

- 纤维处理技术:该厂采用了先进的纤维处理技术,包括高效过滤、无尘生产等,确保生产过程中纤维的质量和安全性。

- 绿色环保材料:现代纺织厂注重使用环保、可持续性的材料,减少对环境的影响,该厂使用可降解材料、天然纤维等环保材料,减少废弃物的产生。

案例分析

以某一家日本现代纺织厂的案例为例,我们可以进一步说明其技术和设备的先进性。

案例:某日本现代纺织厂的生产流程

- 自动化生产系统:该厂采用了先进的机器人生产线和智能控制系统,实现了高效的生产和质量控制,该厂还配备了先进的检测设备,确保产品质量和一致性。

- 纤维处理技术:该厂采用了先进的纤维处理技术,包括高效过滤和静电除尘等,这些技术能够有效地去除纤维中的杂质和污染物,提高纤维的质量和纯度,该厂还采用了先进的环保材料,确保生产过程中对环境的影响最小化。

技术应用与成果

现代纺织厂在技术创新和产业升级方面取得了显著成果,具体表现在以下几个方面:

- 提高生产效率:通过采用先进的自动化生产系统和设备,现代纺织厂实现了更高的生产效率和更好的产品质量。

- 降低生产成本:通过采用环保、可持续性的材料和技术,现代纺织厂降低了生产成本,提高了经济效益。

- 绿色环保:现代纺织厂注重环保、可持续性,打造绿色、健康的纺织产业,该厂的产品受到了消费者的广泛好评和认可。

随着科技的不断发展,日本现代纺织厂将继续加强技术创新和产业升级,提高生产效率和产品质量,同时注重环保、可持续性,打造更加绿色、健康的纺织产业,该厂还将积极探索新的技术和设备,提高生产效率和降低成本,为消费者提供更加优质的产品和服务。

Articles related to the knowledge points of this article:

The Magic of the戴村纺织厂,传统与现代的交织

The Story of Ningbo Best Textile Factory