Is Nylon Fiberboard a Part of Textile Processing?

The nylon fiberboard is not a part of the textile processing. Nylon fiberboard, also known as polyamide fiber board, is a type of engineered wood product made from synthetic nylon fabrics that are woven or knitted into boards. It is used in a variety of industries for its durability and resistance to moisture and chemicals. Textile processing refers to the steps involved in preparing textile materials, such as yarn spinning, weaving, knitting, etc., while nylon fiberboard is a product made from synthetic fibers rather than raw materials used in traditional textile processes.

Text:

When it comes to the textile industry, we often hear about the complexities and intricacies involved in manufacturing fabrics, but have you ever wondered if something like nylon fiberboard falls under the umbrella of textile processing? In this discussion, we'll explore the relationship between nylon fiberboard and the textile sector to determine whether it is indeed a part of the process.

Firstly, it’s important to define what we mean by “textile processing”. Typically, textile processing includes various stages that involve the collection and preparation of raw materials such as cotton, wool, or synthetic fibers, followed by weaving, knitting, sewing, and finishing processes. These steps result in the final product—a piece of clothing, carpet, or any other textile item. So, when we talk about nylon fiberboard, which is essentially a type of non-woven fabric made from synthetic nylon polymers, does it belong to this category?

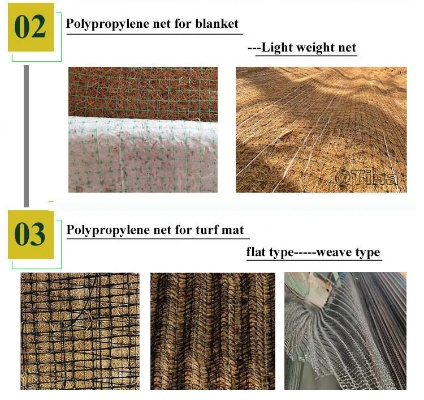

Let's start with some definitions and distinctions. Nylon fiberboard is a type of non-woven fabric that is produced by extruding molten nylon polymer into a continuous sheet, then cooling and solidifying the material. This process results in a lightweight, strong, and durable board that can be molded or cut into various shapes. Unlike traditional woven or knitted textiles that involve intricate stitching and interlacement, nylon fiberboard is akin to a flat, non-woven material that lacks the tactile characteristics of natural textiles.

In terms of its production, nylon fiberboard is typically made through a thermoforming process where hot nylon melt is injected into a mold, allowing for the formation of a continuous sheet. The sheet is then cooled and solidified, resulting in a uniform, high-density board. This method offers a number of advantages over traditional methods such as knitting or weaving, including greater flexibility in design, faster production times, and improved energy efficiency.

Now, let's consider the textile processing stage. While the final product may not involve weaving or knitting, nylon fiberboard is still part of the textile industry because it serves as an essential component in many textile applications. For example, nylon fiberboard is used in the manufacture of protective clothing, sportswear, and automotive interior components. Its strength and durability make it ideal for applications where weight and impact resistance are critical factors.

However, when we delve deeper into the textile processing stage, we find that nylon fiberboard does not fit neatly into the typical categories of weaving, knitting, or sewing. Instead, it falls into the category of non-woven fabrics, which are characterized by their lack of yarn structure and their unique properties compared to traditional woven or knitted fabrics. This means that while nylon fiberboard is a part of the textile industry, it doesn't necessarily fall under the traditional categories of textile processing.

To illustrate, consider the case study of Kleenex, one of the world's leading brands of disposable tissues. Kleenex uses a variety of different materials in its production process, including nylon fiberboard. However, despite its inclusion in the production line, it doesn’t qualify for the same level of classification as traditional woven or knitted tissues. Kleenex is a brand name rather than a textile product, and its value is derived from its brand recognition and marketing strategies rather than its intrinsic textile quality.

In conclusion, while nylon fiberboard is indeed a part of the textile industry due to its role in various textile applications, it does not fit neatly into the traditional categories of weaving, knitting, or sewing. Rather, it belongs to the category of non-woven fabrics, offering unique properties and benefits that distinguish it from traditional textile products. As we continue to explore the complex tapestry of textile processing, it will become clearer how each component plays a vital role in shaping the end product.

亲爱的朋友们,今天我们来聊聊一个日常生活中常见的材料——无纺布,它是否属于纺织品加工呢?让我们一起来探讨一下。

在开始之前,让我们先了解一下什么是纺织品,纺织品是指由纤维材料制成的各种织物,包括但不限于棉布、丝绸、麻布等,而无纺布,作为一种新型材料,在日常生活中应用广泛,尤其在包装、医疗、工业等领域发挥着重要作用。

让我们看看无纺布与纺织品的关联性,从广义的角度来看,无纺布确实属于纺织品的范畴,它是一种通过机械或化学方法将纤维材料进行加工、整理后形成的织物,也就是说,无纺布是通过一系列的纺织工艺过程制成的,满足了纺织品的定义和特征。

为了进一步说明无纺布与纺织品的关联性,我们可以使用一个具体的英文案例来说明,假设我们有一个无纺布生产厂家,他们生产的无纺布产品不仅满足了纺织品的常规要求,还具有独特的特性,他们的无纺布产品采用了特殊的纤维材料,经过特殊的工艺处理,使其具有防水、防潮、防尘等特殊功能,这样的无纺布产品显然是符合纺织品加工的定义的。

我们用英文表格来进一步说明无纺布与纺织品的关联性:

| 英文术语 | 定义/解释 | 无纺布与纺织品的关系 |

|---|---|---|

| 纺织品定义 | 由纤维材料制成的各种织物 | 无纺布是机械或化学方法加工后的纤维织物 |

| 无纺布特性 | 应用广泛,如包装、医疗、工业等 | 属于纺织品的范畴 |

| 无纺布案例 | 无纺布生产厂家生产的具有防水、防潮、防尘等特殊功能的无纺布产品 | 该案例表明无纺布符合纺织品加工的定义和特征 |

在讨论无纺布是否属于纺织品加工时,我们还可以结合一些具体的例子来说明,在包装行业中,无纺布因其独特的性能和广泛的应用领域,已经成为一种重要的包装材料,而在一些特殊的环境下,如医疗领域,无纺布也被用于制作医疗器械和防护用品等,这些例子都充分证明了无纺布属于纺织品加工的范畴。

我们可以得出结论:无纺布属于纺织品加工的范畴,它是一种通过机械或化学方法加工而成的纤维织物,满足了纺织品的定义和特征,在日常生活和工业生产中,无纺布的应用非常广泛,对于满足不同领域的需求起到了重要作用。

Articles related to the knowledge points of this article:

纺织品欧盟Reach and ASTM Standards:A Comprehensive Guide for Manufacturers

The Testing of Textiles for Nucleic Acid