The Fabric of Innovation:An Unconventional Textile Industry

"The Fabric of Innovation: An Unconventional Textile Industry" explores the transformative potential of textiles in today's world. The industry, often perceived as traditional and static, is undergoing a renaissance driven by innovation and technological advancements. This paper delves into the fabric of innovation within the textile sector, highlighting the emergence of new materials, processes, and designs that are revolutionizing the way we perceive and interact with textiles.,Through an analysis of cutting-edge technologies such as biotechnology, nanotechnology, and digital printing, the paper illustrates how these advancements are transforming the textile industry. It emphasizes the importance of sustainable practices and ethical considerations in the production of textiles, particularly in response to environmental concerns and social responsibility.,The paper concludes by suggesting that the textile industry, once viewed as a mundane and unremarkable sector, is now poised for a significant shift towards innovation and sustainability. By embracing new technologies and adopting innovative practices, the textile industry can not only thrive but also play a vital role in shaping the future of our world.

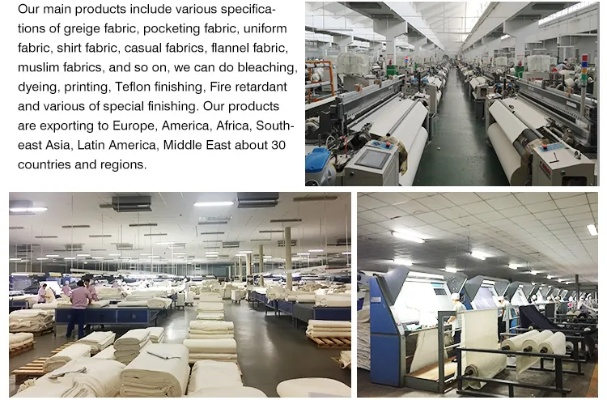

Introduction: In the world of textiles, innovation is not just a buzzword; it's the lifeblood that keeps our industry thriving. In this episode, we delve into the fascinating world of innovative textile manufacturing, specifically focusing on how some of the world's leading textile manufacturers are transforming the way we think about fabrics and their applications. From advanced dyeing techniques to eco-friendly processes, these companies are pushing the boundaries of what's possible in the textile industry.

Case Study: One such company that has revolutionized traditional textile manufacturing is the Swedish textile giant, H&M. Instead of relying solely on mass production, H&M has embraced a more sustainable approach to its supply chain. By adopting a circular economy model, H&M aims to reduce its environmental impact by reducing waste, using renewable materials, and recycling old clothes. This approach not only benefits the planet but also creates a more sustainable future for the industry as a whole.

Another example is the Japanese textile company, Nitto Denko. Nitto Denko has developed a unique process called "bio-dyeing," which uses natural ingredients like plant extracts and bacteria to create vibrant colors without the use of harmful chemicals. This technology not only reduces the environmental footprint of traditional dyeing methods but also offers consumers a healthier option for their clothing.

Advanced Dyeing Techniques: The textile industry is constantly pushing the boundaries of what's possible with dyeing techniques. One such technique is electrostatic printing, which involves using an electric charge to transfer ink onto fabric. This method allows for high-quality prints that are virtually invisible to the naked eye, making them perfect for garments like shirts and dresses.

Another groundbreaking technique is UV-cured printing, which uses ultraviolet light to cure the ink on the fabric. This method eliminates the need for solvents and reduces waste, making it an eco-friendly alternative to traditional dyeing methods.

Eco-Friendly Processes: As the demand for sustainable products continues to grow, textile manufacturers are taking steps to minimize their environmental impact. One such approach is the use of recycled materials in the production process. Companies like Patagonia have become leaders in this space, using recycled polyester and other sustainable materials to create stylish yet environmentally responsible clothing.

Another way manufacturers are working towards sustainability is through water conservation. Many companies are implementing rainwater harvesting systems and low-flow fixtures to reduce their water usage. Additionally, many are investing in energy-efficient technologies like LED lighting and solar panels to further reduce their carbon footprint.

Conclusion: In conclusion, the textile industry is at the forefront of innovation, embracing new technologies and processes to create sustainable and eco-friendly products. From advanced dyeing techniques to eco-friendly processes, these companies are setting new standards for the industry and paving the way for a brighter future. As we continue to demand more from our clothing, it's clear that innovative textile manufacturing will be at the forefront of meeting those demands.

对话者A:你好,我想问一下我们附近的纺织厂是否会染布?

对话者B:这个嘛,纺织厂染布是很常见的业务,纺织厂会生产各种类型的布料,包括但不限于棉布、丝绸、麻布等。 纺织厂染布情况分析

背景介绍

纺织行业作为国民经济的重要支柱产业,其产品种类繁多,包括各种面料、服装、家居用品等,染布作为纺织生产过程中的重要环节,对于满足市场需求、提升产品质量和增加附加值具有重要意义,纺织厂是否染布成为消费者和行业关注的焦点。

纺织厂染布情况分析

染料种类与质量

纺织厂染布主要采用各种类型的染料进行染色,根据市场需求和产品质量要求,纺织厂会选择适合的染料进行染色,确保染出来的布料符合质量标准,纺织厂还会注重染料的环保性、安全性等方面,确保染料符合相关法规和标准。

生产工艺与设备

纺织厂染布的生产工艺和设备是影响染布质量的重要因素,先进的生产工艺和设备可以提高染布的均匀性、色牢度等指标,同时还可以提高染布的生产效率和产品质量,纺织厂还会注重染布的环保性、节能性等方面,采用环保材料和节能设备,降低生产成本和环境污染。

市场需求与经营状况

随着人们生活水平的提高和消费观念的转变,人们对纺织品的需求不断增加,纺织行业的发展也呈现出多元化、高端化的趋势,纺织厂在经营状况方面也呈现出良好的态势,一些规模较大的纺织厂还会注重技术创新和品牌建设,提高产品的附加值和市场竞争力。

案例说明

以某纺织厂为例,该纺织厂近年来在染布方面取得了显著的成绩,该纺织厂采用了先进的生产工艺和设备,选用优质的染料进行染色,同时注重染料的环保性、安全性等方面,该纺织厂还注重技术创新和品牌建设,不断提高产品的质量和附加值。

该纺织厂生产的布料质量稳定可靠,深受消费者喜爱,该纺织厂还注重市场拓展和销售渠道建设,积极开展线上线下销售活动,提高产品的知名度和市场占有率,该纺织厂还积极参与行业交流和合作活动,加强与上下游企业的联系和合作,提高产业链的整体效益。

结论与建议

纺织厂是否染布取决于市场需求、生产工艺和设备、染料种类和质量等多个因素,在纺织行业的发展过程中,纺织厂需要注重技术创新和品牌建设,不断提高产品的质量和附加值,政府和相关部门也需要加强对纺织行业的监管和管理,促进纺织行业的健康发展。

针对以上分析,建议纺织厂在未来的发展中可以采取以下措施:一是加强技术创新和研发能力建设,不断提高产品的技术含量和附加值;二是注重环保和可持续发展,采用环保材料和节能设备,降低生产成本和环境污染;三是加强市场拓展和销售渠道建设,提高产品的知名度和市场占有率;四是积极参与行业交流和合作活动,加强与上下游企业的联系和合作,提高产业链的整体效益。

Articles related to the knowledge points of this article:

A Brief Overview of the Aobo Textile Factory

The Dynamics of Chengan Hotpot Textile Mill