The Role of Textile Testing Scissors in Ensuring Quality and Safety

The importance of textile testing scissors in ensuring product quality and safety cannot be overstated. These specialized tools are designed to perform precise cuts, ensuring that fabric samples meet the standards set by industry regulations. The use of these scissors is crucial for manufacturers who want to avoid defects in their products, as any mistakes can lead to costly rework or even recalls of the finished goods. Additionally, the precision and accuracy of these scissors contribute to the overall quality of the final product, as they ensure that each piece meets the necessary specifications. Ultimately, the role of textile testing scissors is not just about cutting; it's about ensuring that every stitch counts, every thread is perfect, and every garment is safe for wear.

Introduction: The textile industry is a crucial sector that contributes significantly to global economic growth through the production of clothing, fabrics, and other materials. However, this sector is also prone to errors and defects that can compromise product quality and safety. One essential tool for ensuring these products meet standards is the textile testing scissor. In this article, we will explore the importance of textile testing scissors, their role in quality control, and how they can be used effectively to ensure safe products.

Textile Testing Scissors: What Are They?

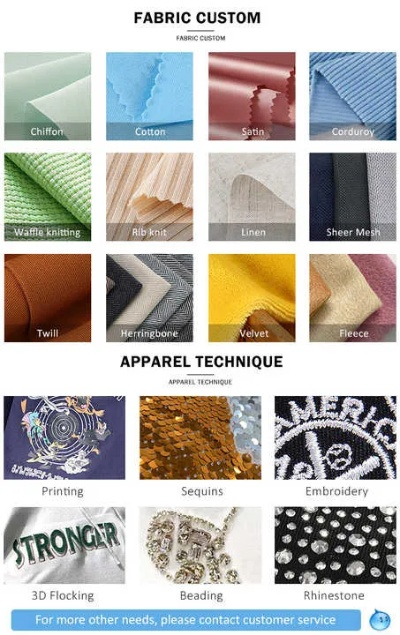

Testing scissors are specialized tools designed specifically for use in textile testing. These scissors are typically made from high-quality stainless steel or other durable materials, which ensures they can withstand the rigors of repeated use without rusting or breaking. The blades on these scissors are sharpened to a precise angle, allowing for accurate cutting of various types of fabrics, including cotton, linen, and synthetic fibers.

The Importance of Textile Testing Scissors in Quality Control

Quality control is critical in the textile industry, as any defects or flaws in a product can have serious consequences. Using textile testing scissors, manufacturers can identify and rectify issues before they reach the consumer, reducing the risk of complaints and lawsuits. By using these scissors, manufacturers can ensure that all fabrics meet the necessary standards and specifications, which include proper weight, thickness, and color consistency.

Effective Use of Textile Testing Scissors

To ensure that textile testing scissors are being used effectively, it is important for manufacturers to follow proper procedures. Firstly, they should thoroughly clean the scissors after each use to prevent cross-contamination of different fabrics. Secondly, they should use the correct blade angle for the type of fabric being cut, which can vary depending on the material's density and texture. Thirdly, they should inspect the fabric for any signs of damage or defects before finalizing the order.

Examples of How Textile Testing Scissors Can Be Used to Ensure Safe Products

One example of how textile testing scissors can be used to ensure safe products is in the case of a garment manufacturer. For example, if a manufacturer notices that a certain fabric has been cut too short, they can use the scissors to adjust the length and ensure that the garment fits properly. This can help prevent customer complaints and potential legal action.

Another example is in the case of a textile company that produces high-quality bedsheets. If a supplier reports that a batch of sheets had an issue with thread count, the manufacturer can use the testing scissors to verify the accuracy of the measurements before shipping the product. This can help prevent customers from receiving defective sheets and minimize the risk of complaints.

Conclusion: In conclusion, textile testing scissors play a crucial role in ensuring quality and safety in the textile industry. By following proper procedures and using these tools effectively, manufacturers can identify and rectify issues before they reach the consumer, reducing the risk of complaints and lawsuits. As such, investing in high-quality textile testing scissors is essential for any manufacturer looking to maintain a reputable brand and satisfy their customers' needs.

大家好,今天我们将围绕“纺织品检测剪刀”这一主题展开讨论,纺织品作为我们日常生活中不可或缺的物品,其质量直接关系到人们的健康和安全,对纺织品进行严格的检测是确保其质量的重要手段,本文将通过案例分析、检测标准介绍以及英文案例说明等方式,为大家详细介绍纺织品检测剪刀的使用方法和相关检测标准。

纺织品检测剪刀的基本介绍

纺织品检测剪刀是一种用于检测纺织品质量的专业工具,它通常由剪刀头、刀片、夹具等部分组成,具有高精度、高效率的特点,在检测过程中,纺织品检测剪刀能够快速准确地识别出纺织品中的各种问题,如纤维含量、颜色、纤维类型等。

纺织品检测剪刀的使用方法

-

使用前准备 在使用纺织品检测剪刀之前,需要先检查剪刀的锋利度、夹具的牢固度等,确保剪刀和夹具处于良好状态,以便进行准确的检测。

-

样品处理 将待检测的纺织品样品放置在夹具中,确保样品平整、无破损,根据检测需求,对样品进行适当的预处理,如清洗、烘干等。

-

操作步骤 (1)打开剪刀开关,调整剪刀的切割速度和力度,以便准确识别纺织品中的问题。 (2)将夹具固定在检测设备上,确保夹具与样品紧密贴合。 (3)进行检测,观察剪刀的切割效果,记录检测结果。

纺织品检测标准介绍

-

纤维含量标准 纤维含量是衡量纺织品质量的重要指标之一,根据国家标准,纤维含量应符合一定的比例范围,以确保纺织品的舒适性和耐用性。

-

颜色标准 颜色是纺织品的重要特征之一,根据国家标准,颜色应符合一定的标准范围,以确保纺织品的外观美观和舒适性,对于某些特殊用途的纺织品,还需要符合特定的颜色标准。

-

检测方法与流程 纺织品检测通常采用化学分析、显微镜观察等方法,具体流程包括样品准备、样品处理、检测操作等步骤,在检测过程中,需要严格按照国家标准和检测流程进行操作,以确保检测结果的准确性和可靠性。

英文案例说明

以某品牌纺织品检测剪刀为例,该品牌采用了先进的检测技术,能够快速准确地识别纺织品中的各种问题,该品牌使用的纺织品检测剪刀具有高精度、高效率的特点,能够快速准确地识别出纺织品中的纤维含量问题,该品牌还采用了多种检测方法,包括化学分析、显微镜观察等,以确保检测结果的准确性和可靠性,该品牌还提供了详细的检测报告和用户手册,以便用户更好地了解和使用该品牌的产品。

纺织品作为我们日常生活中不可或缺的物品,其质量直接关系到人们的健康和安全,对纺织品进行严格的检测是确保其质量的重要手段,本文通过案例分析、检测标准介绍以及英文案例说明等方式,为大家详细介绍了纺织品检测剪刀的使用方法和相关检测标准,我们也希望广大消费者能够更加重视纺织品的检测工作,选择质量可靠的纺织品产品。

Articles related to the knowledge points of this article:

Chinas Textile Market Overview and Recent Trends

Civilizations Fabric:The Renewal of Textile Waste into Sustainable Products

Understanding the Price Ranges of Common Textile Products in Jiangsu

The Role of Textile Ingredients in the Quality and Durability of Clothing

Strategies for Degrading Formaldehyde in Textile Products

An Extensive Guide to Printed Textiles:Types,Uses,and Case Studies