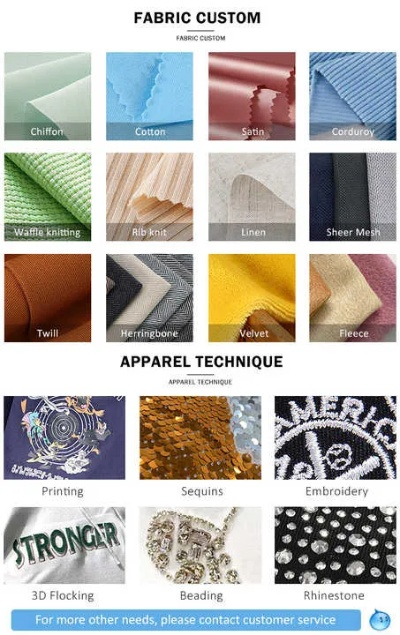

Understanding the Language of Textile Defects:A Comprehensive Guide

This comprehensive guide aims to provide a thorough understanding of the language of textile defects, providing readers with an in-depth analysis of common types of defects and their causes. The guide covers various aspects of textile production, including materials, processes, and quality control, and emphasizes the importance of identifying and addressing these defects to ensure high-quality products. By following this guide, readers can become proficient in identifying and diagnosing textile defects, and take steps to improve their knowledge and skills in this area.

I. Introduction Textile products are an essential part of our lives, from clothing to furnishings and even industrial materials. However, like any product, textiles can be subject to various defects that affect their quality, functionality, and aesthetic appeal. In this guide, we will explore the different types of textile defects and how they can be described in English using a table format. By understanding these terms, you will be better equipped to communicate about the issues you encounter when inspecting or dealing with textile products.

II. Common Textile Defects

A. Fabric Blemishes

- Pinholes (Pin Holes)

- Tear or Cut (Tear or Cut)

- Fray (Fray)

- Stain (Stain)

- Burn (Burn)

- Stretchmarks (Stretchmarks)

- Dye Run (Dye Run)

- Pills (Pills)

- Puffiness (Puffiness)

- Mottle (Mottle)

B. Weave Distortions

- Warp Breaks (Warp Breaks)

- Weft Breaks (Weft Breaks)

- Loom Marks (Loom Marks)

- Worn Out (Wonn Out)

- Uneven Gauge (Uneven Gauge)

- Uneven Color (Uneven Color)

- Uneven Weave (Uneven Weave)

- Uneven Tension (Uneven Tension)

- Uneven Turn (Uneven Turn)

- Uneven Pick Up (Uneven Pick Up)

C. Finishing Defects

- Scratches (Scratches)

- Peeling (Peeling)

- Bubbling (Bubbling)

- Rust (Rust)

- Staining (Staining)

- Cracking (Cracking)

- Oxidation (Oxidation)

- Stains (Stains)

- Foaming (Foaming)

- Piling (Piling)

III. Textile Defect Description Table

| Textile Defect | Description | Example |

|---|---|---|

| Pinholes | Small holes in the fabric | "Several pinholes visible on the sleeve of the shirt." |

| Tear or Cut | Large tears or cuts in the fabric | "The dress has several large tears along the hemline." |

| Fray | The fabric is frayed at the edges | "The blanket has frayed edges that need to be repaired." |

| Stain | A stain on the fabric | "The carpet has a dark stain on it." |

| Burn | A burn mark on the fabric | "The fabric has a burn mark on the arm of the jacket." |

| Stretchmarks | Straight lines or marks on the fabric | "The pants have stretchmarks running down the leg." |

| Dye Run | Transferred color from another area onto the fabric | "The shirt has a dye run from the collar to the sleeve." |

| Pills | Small balls of fiber that form inside the fabric | "The sweater has several pills in the cuff area." |

| Puffiness | Bubbles or bulges in the fabric | "The blanket has puffiness around the edges." |

| Mottle | A mottled or discolored appearance in the fabric | "The curtains have a mottled appearance due to age." |

IV. Case Study: Textile Defect Identification

A. Problem Identified

- Product: A pair of jeans

- Issue: A significant amount of fraying in the knees area

B. Inspection Process

- Step 1: Visual inspection for obvious signs of damage

- Step 2: Examination of the fabric under magnification to identify individual fibers and threads

- Step 3: Testing for specific dyes or chemicals that could cause fraying

C. Analysis and Diagnosis

- Based on visual inspection, it was determined that the fraying was caused by overly aggressive washing methods.

- Microscopy revealed that the fraying was due to a combination of high-temperature wash cycles and improper care during drying.

- Further testing showed that the jeans were made with a blend of polyester and cotton, which is more prone to fraying than pure polyester or cotton.

D. Solution and Recommendations

- To prevent future fraying, recommend washing the jeans in cold water and air drying them instead of machine drying.

- For immediate repairs, use a specialized thread fray repair kit to reinforce the weak areas.

- Suggestions for the manufacturer include incorporating a stronger stitching pattern or using a higher-quality polyester blend that is less prone to fraying.

V. Conclusion

Textile defects can significantly impact the quality and usability of textile products. By understanding the common types of defects and their descriptions using a table format, you can better communicate about these issues when inspecting or dealing with textile products. Additionally, case studies demonstrate how to identify, analyze, and diagnose textile defects through a systematic approach. With this knowledge, you can proactively address these issues before they become more serious problems, ensuring the longevity and durability of your textile products.

在日常交流中,我们经常遇到纺织品质量问题,今天我们将以英语描述的形式,详细阐述纺织品常见的缺陷及其产生原因,以下内容将结合英文案例和表格进行说明,以便更好地理解和应对纺织品缺陷问题。

常见纺织品缺陷概述

-

织物起皱 英文描述:A noticeable wrinkle appears on the fabric surface. 表格说明:起皱通常是由于织物纤维在拉伸过程中未得到适当的松弛,或者处理不当导致纤维过度收缩。

-

纱线断裂 英文描述:A noticeable break in the yarn occurs during the production process or after use. 表格说明:纱线断裂可能是由于纱线材料本身的问题,如纤维强度不足或生产工艺不当。

-

色差不均 英文描述:A noticeable variation in color intensity or distribution across the fabric. 表格说明:色差不均可能是由于染料分布不均匀、织物处理不当或染料与纤维不兼容等原因导致。

-

质地不均匀 英文描述:A noticeable uneven texture on the fabric surface. 表格说明:质地不均匀可能是由于织物纤维分布不均匀、织物结构不合理等原因导致。

-

异味或杂质 英文描述:An unpleasant odor or foreign particles are present on the fabric. 表格说明:异味或杂质可能是由于纺织品在生产或使用过程中受到污染,或者材料本身存在杂质。

案例分析

纺织品起皱问题

描述:某品牌的一款丝绸面料在使用过程中出现了明显的起皱现象,经过调查,发现是由于生产过程中的温度和湿度控制不当,导致纤维在拉伸过程中未能得到适当的松弛。

表格说明:根据该案例,我们可以看到起皱问题的产生原因主要是生产过程中的温度和湿度控制不当,以及纤维在拉伸过程中的松弛不足,为了解决这一问题,可以采取改进生产工艺、优化温度和湿度控制等措施。

纱线断裂问题

描述:某品牌的一款棉质衣物在使用过程中出现了纱线断裂现象,经过调查,发现可能是由于纱线材料本身的问题,如纤维强度不足,为了解决这一问题,可以更换强度更高的纱线材料。

表格说明:根据该案例,纱线断裂问题的产生原因主要是纱线材料本身的问题,如纤维强度不足,为了防止类似问题的再次发生,需要选择高质量的纱线材料,并采取相应的质量控制措施。

预防与处理措施

-

预防措施: (1)严格控制生产过程中的温度和湿度,确保纤维在拉伸过程中得到适当的松弛。 (2)选用高质量的纱线材料,并采取相应的质量控制措施。 (3)加强生产过程中的清洁和整理工作,确保纺织品在使用过程中不受污染。 (4)采用先进的织物处理技术,提高织物的抗皱性和质地均匀性。

-

处理措施: (1)对于起皱问题,可以采用熨烫、拉伸等方式进行处理,恢复织物的平整度和美观度。 (2)对于纱线断裂问题,可以采取更换纱线、修补等方式进行处理,加强后续的维护和保养工作也是非常重要的。

总结与建议

纺织品缺陷问题是一个比较复杂的问题,需要从多个方面进行考虑和处理,在生产过程中,需要严格控制质量标准,加强质量控制措施;还需要加强后续的维护和保养工作,确保纺织品在使用过程中不受污染和损坏,针对以上案例和分析结果,我们提出以下建议:

加强质量监管,提高纺织品质量标准,政府和相关机构应该加强对纺织品质量的监管和检测力度,制定更加严格的质量标准,确保纺织品的质量和安全。

加强技术创新,提高纺织品性能和质量,企业应该加强技术创新和研发工作,采用先进的织物处理技术、染料和纱线材料等,提高纺织品的性能和质量,满足消费者的需求和期望。

加强消费者教育,提高消费者对纺织品质量的认识和意识,消费者应该了解纺织品质量的重要性,选择正规品牌和渠道购买纺织品,加强后续的维护和保养工作,确保纺织品在使用过程中不受污染和损坏。

Articles related to the knowledge points of this article:

The Determining Factors of Textile Oil Content

The Fabric of Innovation:A Look at Wenzhou Huanhong Textiles

The Global Trends and Influence of British Textile Sales in India

A Glimpse into the World of Nanjing FancǎTextiles

Suzhou Xinying Textiles:Navigating the Global Fashion Industry