纺织厂订单通知 A Comprehensive Guide for Manufacturers and Customers

: A Comprehensive Guide for Manufacturers and Customers,This comprehensive guide aims to provide a detailed overview of the textile industry, including the latest trends, market dynamics, and best practices for both manufacturers and customers. It covers topics such as product sourcing, quality control, supply chain management, and customer service, offering practical advice and strategies for success in today's competitive marketplace.,The guide begins with an introduction to the textile industry, explaining its historical background and current state. It then provides an overview of the different types of textile products, their uses, and how they are produced. This section also highlights the importance of sustainability and environmental responsibility in the textile industry, emphasizing the need for manufacturers to adopt eco-friendly practices.,Moving on to the manufacturing process, the guide covers everything from raw material procurement to finished product assembly. It emphasizes the importance of quality control, including testing and inspection processes, and discusses the various techniques used in the production process to ensure consistency and reliability.,In addition to the manufacturing process, the guide also addresses the challenges faced by manufacturers in terms of supply chain management. It explores issues such as inventory management, logistics, and transportation, and offers strategies for managing these complexities effectively.,Finally, the guide focuses on customer service and satisfaction, discussing how to build strong relationships with customers and address any concerns or complaints promptly and effectively. It includes tips on communication, pricing, and packaging, among other areas.,Overall, this comprehensive guide is designed to help manufacturers and customers alike navigate the ever-evolving landscape of the textile industry, providing valuable insights and strategies for success in today's competitive marketplace.

I. Introduction A. Overview of the Text This text provides a comprehensive overview of textile industry orders, including the process, format, and key points to be noted during the order cycle. It also highlights the importance of understanding the different types of orders and their implications on inventory management and production planning.

B. Importance of Order Management in the Textile Industry Order management is crucial for the textile industry as it affects the efficiency of production, inventory levels, and customer satisfaction. Proper order management can help manufacturers stay competitive and meet the demands of their customers.

II. The Process of Order Management in the Textile Industry A. Steps in Order Management

-

Accepting Orders Manufacturers receive orders from customers through various channels such as phone, email, or online platforms. These orders are then reviewed by the sales team to determine if they are viable and within the manufacturer's capacity.

-

Quotation and Pricing Once an order is accepted, the sales team will prepare a quotation based on the product specifications, quantity, and delivery timeline. The quotation should include all relevant costs, including raw material prices, labor, transportation, and taxes.

-

Negotiation and Finalization Customers may negotiate the price and terms of the order with the manufacturer. Once a mutually agreed-upon agreement is reached, the order becomes finalized and is recorded in the order management system.

-

Production Planning Based on the finalized order, production planning is initiated to determine the required materials, equipment, and workforce. This process involves scheduling workshops, purchasing raw materials, and assigning tasks to employees.

-

Quality Control Quality control checks are conducted during the production process to ensure that the products meet the required standards. Any defects found during this stage are reported to the customer and resolved before shipment.

-

Shipping and Packaging Once the products are ready for shipment, they are packed and prepared for shipping. The shipping method and packaging materials are chosen based on the product type and destination.

-

Invoice Generation and Shipment The manufacturer generates an invoice detailing the products and services provided, including the cost of goods sold, freight charges, and any applicable taxes. The invoice is then sent to the customer, who pays the balance due before the products are shipped.

-

Documentation and Follow-Up After the products are shipped, documentation is generated to track the shipment and confirm receipt by the customer. If there are any issues or delays, the manufacturer will follow up with the customer to resolve any concerns.

III. Key Points to Note During the Order Cycle A. Product Specifications

-

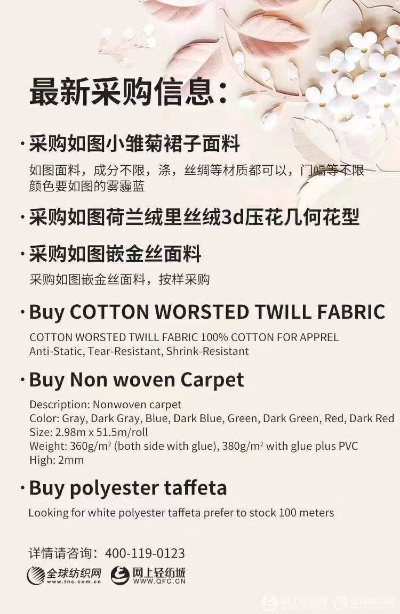

Design Requirements Product specifications should include detailed design requirements, including dimensions, colors, patterns, and finishes. These specifications must be clear and communicated effectively to both manufacturers and customers.

-

Quality Standards Quality standards should be established and communicated to both manufacturers and customers to ensure that the products meet the required standards. This includes testing procedures, inspection methods, and quality control measures.

-

Packaging Requirements Packaging requirements should be clearly defined to ensure that the products are protected during transit and meet legal requirements for export or import. This includes weight limits, dimensions, and any special handling instructions.

B. Supply Chain Management

-

Raw Material Availability Manufacturers must maintain a good supply chain to ensure that they have enough raw materials to produce their orders. This includes sourcing suppliers, managing inventory levels, and monitoring raw material prices.

-

Transportation Costs Transportation costs should be factored into the order pricing to ensure that customers are aware of the potential expenses associated with shipping their products. This includes freight charges, customs duties, and insurance fees.

-

Warehousing Space Warehousing space should be allocated based on the size and volume of orders received. This ensures that manufacturers have adequate storage facilities to handle the products during production and shipping periods.

IV. Case Study: Successful Order Management in a Textile Factory A. Company Background XYZ Textile Factory has been operating in the textile industry for over 20 years and specializes in producing high-quality garments for both domestic and international markets. The company has a strong reputation for delivering timely and reliable orders while maintaining excellent customer service.

B. Order Management Process During the past year, XYZ Textile Factory successfully managed several large orders from various customers. Each order was carefully reviewed and approved by the sales team before being placed in the order management system. The company used advanced software to track the progress of each order, ensuring that all necessary information was available at all times.

C. Challenges Faced and Solutions Found One challenge faced by XYZ Textile Factory was managing multiple orders simultaneously. To address this issue, the company implemented a centralized order management system that allowed for easy tracking and communication between sales teams and production teams. Additionally, the company regularly trained its staff on best practices for order management, including time management and communication skills.

D. Results of Successful Order Management Through effective order management, XYZ Textile Factory achieved significant growth in its business. The company's ability to deliver high-quality products on time helped it build strong relationships with its customers and secure repeat business. Additionally, the company's efficient order management system reduced waste and improved productivity, resulting in increased profitability.

V. Conclusion A. Recap of Key Points In conclusion, successful order management in the textile industry requires careful planning, communication, and collaboration among all stakeholders. By following the steps outlined in this text, manufacturers can ensure that they are meeting the needs of their customers while maintaining optimal inventory levels and production schedules.

B. Call to Action for Manufacturers and Customers Manufacturers should invest in modern order management systems to streamline their processes and improve efficiency. Customers should communicate their needs clearly and provide accurate specifications to avoid delays and errors in production. Both parties should work together to create a win-win situation that benefits both parties involved in the order cycle.

订单背景

纺织厂接到了大量的订单需求,为了确保生产进度和产品质量,我们特此向您发出订单通知,本次订单涉及的主要产品为XX系列纺织品,预计将用于XX市场。

订单详情

- 产品数量与规格:本次订单涉及XX件纺织品,具体规格和数量需根据客户具体需求进行确定。

- 生产周期:根据订单需求和原材料供应情况,预计生产周期为XX周。

- 质量标准:我们将严格按照国家相关标准和客户要求进行生产,确保产品质量符合国家标准。

订单支持与服务

为了确保订单顺利完成,纺织厂提供以下支持与服务:

- 原材料供应保障:我们将与优质供应商紧密合作,确保原材料供应稳定可靠。

- 生产技术指导:我们将为您提供专业的生产技术指导和售后服务,确保生产过程顺利进行。

- 质量检测与验收:我们将严格按照国家相关标准和客户要求进行质量检测和验收,确保产品质量符合要求。

案例说明

为了更好地说明本次订单的实际情况,我们特此提供一份案例说明:

某纺织厂在接到订单后,积极响应市场需求,与优质供应商紧密合作,确保原材料供应稳定可靠,该厂还提供了专业的生产技术指导和售后服务,确保生产过程顺利进行,该纺织厂成功完成了订单,并得到了客户的良好评价。

后续安排

为了确保订单顺利完成,纺织厂将按照以下安排进行后续工作:

- 安排生产计划:根据订单需求和原材料供应情况,纺织厂将制定详细的生产计划,确保生产进度和产品质量。

- 加强质量管理:纺织厂将加强质量管理,严格按照国家相关标准和客户要求进行生产,确保产品质量符合要求,纺织厂还将定期对生产过程进行质量检测和验收,确保生产过程符合标准。

- 提供售后服务:纺织厂将提供专业的售后服务,包括产品维修、退换货等服务,以确保客户在使用产品过程中得到满意的体验。

结束语

感谢您对我们纺织厂的信任和支持,我们将继续努力,为您提供优质的产品和服务,如果您有任何疑问或需要进一步了解订单详情,请随时与我们联系,以下是联系方式:

联系人:[联系人姓名] 电话:[联系人电话] 邮箱:[联系人邮箱]

此致 敬礼!

附件:无(如有需要可添加表格或图片)

Articles related to the knowledge points of this article:

The Story of Suzhous Loom and Yarn Manufacturing