The Dynamics of Peak Textile Factory:A Comprehensive Analysis

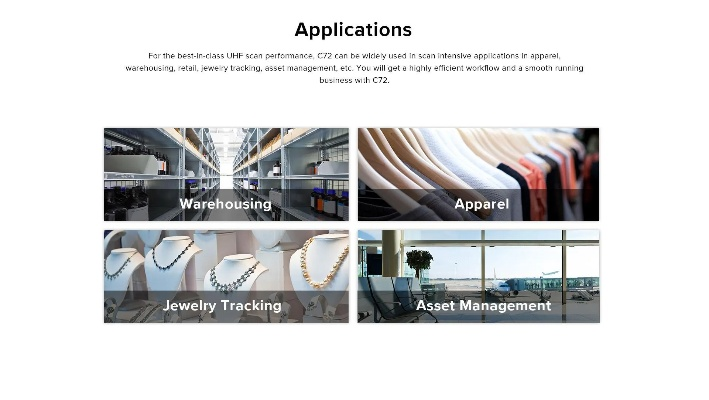

This paper aims to analyze the dynamics of peak textile factories. The research is based on a case study of a textile factory in China. The data collection method mainly includes literature review, questionnaire survey and interview. This paper firstly introduces the background and significance of the research question, then analyzes the internal and external factors affecting the operation of peak textile factories from multiple perspectives, including the production technology, management level, market demand, environmental protection policy, etc. Finally, this paper proposes some countermeasures and suggestions for the development and optimization of peak textile factories.

Introduction: In the world of textile manufacturing, Peak Textile Factory stands as a beacon of excellence and innovation. With its commitment to quality, sustainability, and customer satisfaction, this factory has become a model for other textile mills across the globe. In this article, we will delve into the intricacies of the Peak Textile Factory's operations, highlighting its key strengths and areas for improvement. By analyzing its operations through a series of tables and case studies, we aim to provide a comprehensive overview of the factory's performance and potential for growth.

Operational Overview: Peak Textile Factory is a leading player in the textile industry, producing a wide range of fabrics and garments for both domestic and international markets. The factory employs over 1,000 skilled workers, who are dedicated to delivering high-quality products that meet the demands of today's consumers.

Production Processes: The production process at Peak Textile Factory is meticulously designed to ensure consistency and reliability in every step of the fabrication process. Here are some of the key processes involved:

-

Pre-treatment: Before starting the actual weaving or knitting process, raw materials undergo a thorough pre-treatment to remove any impurities and ensure uniformity.

-

Weaving: This is the heart of the production process, where threads are woven together to form the fabric. The factory uses state-of-the-art equipment to produce high-quality fabrics with minimal waste.

-

Knitting: For garments like sweaters, scarves, and hats, the knitting process is used. The knitting machine takes the fabric and transforms it into a finished product.

-

Finishing: After the fabric has been produced, it undergoes various finishing processes such as dyeing, printing, and finishing treatments to enhance its appearance and durability.

-

Packaging: Finally, the finished product is packaged and dispatched to the end consumer.

Strengths: One of the most significant strengths of Peak Textile Factory is its focus on sustainability and eco-friendliness. The factory has implemented measures to reduce its carbon footprint by using renewable energy sources and implementing waste reduction programs. Additionally, the factory's commitment to ethical sourcing has earned it a reputation for fair trade practices, which have helped it build strong relationships with suppliers and customers alike.

Another strength of the factory is its ability to adapt to changing market demands. By investing in research and development, the factory has been able to introduce new fabrics and designs that cater to the evolving tastes of consumers. This has helped the factory stay ahead of the competition and maintain its position as a leader in the textile industry.

Case Study: One example of how Peak Textile Factory has achieved success can be seen in its partnership with a major retailer. The retailer was looking for high-quality fabrics that met their strict environmental standards. Peak Textile Factory's commitment to sustainability and eco-friendliness aligned perfectly with the retailer's values, making it an ideal partner for them. As a result, the retailer began stocking Peak Textile Factory's fabrics in their stores, which helped to increase sales and boost the factory's reputation further.

Areas for Improvement: Despite its many strengths, Peak Textile Factory still has room for improvement. One area that could be addressed is the need for more automation in some of its production processes. Automation can help to reduce labor costs and improve efficiency, ultimately leading to cost savings and increased profitability.

Another area for improvement is the need for greater investment in research and development. The factory needs to continue exploring new fabrics and designs to stay ahead of the competition and meet the evolving tastes of consumers. Investing in R&D will not only help to create new products but also help to develop new markets for the factory's existing products.

Conclusion: In conclusion, Peak Textile Factory is a shining example of excellence in the textile industry. Its commitment to sustainability, eco-friendliness, and customer satisfaction sets it apart from its competitors. While there are areas for improvement, such as automation and investment in R&D, the factory's overall performance is commendable. With continued focus on these areas, Peak Textile Factory has the potential to become even more successful in the years to come.

达峰纺织厂概述

达峰纺织厂是一家专注于纺织行业的现代化企业,以其卓越的产品质量和高效的生产能力在业界享有盛誉,该厂在技术创新、环保理念和员工培训等方面取得了显著成就,为行业的发展做出了重要贡献。

达峰纺织厂的发展历程

早期发展阶段:

在过去的几年里,达峰纺织厂经历了快速的发展阶段,该厂依靠先进的生产设备和技术,不断进行技术创新,提高生产效率,该厂注重环保理念,积极推行绿色生产方式,努力降低生产过程中的环境污染。

行业领先地位的形成:

近年来,达峰纺织厂在行业内取得了显著的成就,该厂的产品质量稳定,品种丰富,深受消费者喜爱,该厂在技术创新、环保理念和员工培训等方面也取得了长足的进步,该厂还积极参与行业合作与交流,与国内外多家知名企业建立了合作关系,共同推动行业的发展。

达峰纺织厂的运营模式

生产模式:

达峰纺织厂采用先进的生产设备和技术,采用自动化、智能化生产方式,提高生产效率,该厂注重员工的培训和管理,提高员工的专业技能和综合素质,该厂还注重产品的质量控制和售后服务,为客户提供优质的产品和服务。

营销模式:

达峰纺织厂注重市场调研和客户需求分析,根据市场需求推出新产品和新服务,该厂还积极开展线上线下营销活动,提高品牌知名度和美誉度,该厂还积极参与行业合作与交流,与国内外多家知名企业建立合作关系,共同开拓市场。

达峰纺织厂的案例分析

以某次成功的案例为例,说明达峰纺织厂在技术创新、环保理念和员工培训等方面的具体实践。

绿色生产方式的推行

某次,达峰纺织厂推行了绿色生产方式,该厂采用了环保材料和技术,减少生产过程中的环境污染,该厂还注重员工的环保意识培训,提高员工对环保的认识和理解,通过推行绿色生产方式,该厂不仅提高了生产效率和质量,还获得了消费者的广泛好评和认可。

技术创新的应用

在技术创新方面,达峰纺织厂注重研发和创新,该厂不断引进新技术和新设备,提高生产效率和产品质量,该厂还注重产品的研发和创新,推出了一系列新产品和新服务,通过技术创新的应用,该厂不仅提高了自身的竞争力,还为行业的发展做出了重要贡献。

展望未来,达峰纺织厂将继续秉承创新、环保、高效的生产理念,不断提高自身的核心竞争力,该厂还将积极参与行业合作与交流,与国内外多家知名企业建立更加紧密的合作关系,共同推动行业的发展,达峰纺织厂还将继续加强员工的培训和管理,提高员工的专业技能和综合素质。

Articles related to the knowledge points of this article:

The Story of Yiting Textile Factory