The Taiwanese Unmanned Textile Factory Revolution

The Taiwanese Unmanned Textile Factory Revolution is a significant development in the field of textile manufacturing. This revolutionary technology has transformed the traditional textile industry by introducing unmanned machinery and automation systems that enable efficient production and cost-effectiveness. The adoption of this technology has significantly reduced labor costs, increased production efficiency, and improved product quality.,Moreover, the use of unmanned machinery in the Taiwanese textile factory revolution has also contributed to environmental sustainability. The reduction in energy consumption and waste generation due to the efficient use of resources in the production process have made the textile industry more eco-friendly.,Furthermore, this technological advancement has also led to the creation of new job opportunities in the industry. Many workers have been retrained and upgraded to work with the latest machinery, leading to increased employment rates and improved economic growth.,In conclusion, the Taiwanese Unmanned Textile Factory Revolution has brought about significant changes in the textile industry, making it more efficient, cost-effective, and sustainable. It has also created new job opportunities and improved economic growth in the region.

Introduction: The emergence of the Taiwanese unmanned textile factory is a testament to technological advancements and the future-oriented approach towards manufacturing. This innovative concept has not only disrupted traditional textile production but also paved the way for more efficient, sustainable, and cost-effective production methods. In this article, we will delve into the details of this revolutionary technology, including its impact on the industry, challenges faced, and its potential for global adoption.

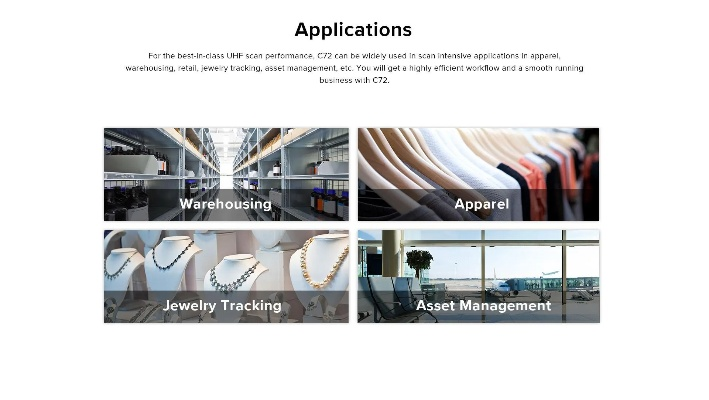

Impact on the Industry: The unmanned textile factory in Taiwan has revolutionized the textile industry by reducing labor costs, enhancing production efficiency, and minimizing waste. By using advanced robotics and automation systems, these factories can produce high-quality textiles at a faster pace than traditional manual labor. This not only saves time and resources but also reduces the risk of human error, which is often associated with manual production.

In addition to cost savings, the unmanned textile factory offers significant environmental benefits. By eliminating the need for large numbers of workers, these factories can reduce energy consumption and emissions, making them carbon-neutral or even carbon-negative. This not only contributes to a healthier environment but also attracts investors who prioritize sustainability over profitability.

Challenges Faced: While the unmanned textile factory presents numerous advantages, it also faces several challenges that must be addressed for widespread adoption. One of the main challenges is the initial investment required to invest in new technologies and infrastructure. These factories require substantial capital to purchase sophisticated machinery and software, as well as to train workers who can operate these machines effectively.

Another challenge is the lack of skilled labor in some regions. As these factories become more automated, there may be a shortage of skilled workers who can operate the machines and maintain the equipment. This could lead to higher labor costs and reduced productivity.

Finally, there is the issue of regulatory compliance. Many countries have strict regulations on labor practices and safety standards, and the unmanned textile factory requires adherence to these regulations. Companies must ensure that they comply with all applicable laws and regulations, which can be a complex and time-consuming process.

Case Study: One example of the successful implementation of the unmanned textile factory in Taiwan is the establishment of the AiRobot Textile Co. Ltd. This company uses robotic arms and automated assembly lines to produce high-quality garments at a significantly lower cost than traditional production methods. By investing in advanced robotics and automation systems, AiRobot Textile Co. Ltd. was able to achieve a 30% reduction in labor costs and a 25% increase in production capacity within just two years.

Conclusion: The unmanned textile factory in Taiwan represents a significant step forward in the evolution of the textile industry. By reducing labor costs, enhancing production efficiency, and minimizing waste, these factories offer a more sustainable and cost-effective alternative to traditional production methods. While there are challenges to overcome, the potential benefits of unmanned textile factories cannot be ignored. As the industry continues to embrace these innovations, we can expect to see further improvements in production efficiency, quality control, and environmental sustainability.

背景介绍

近年来,台湾地区涌现出一批无人纺织厂,这些工厂以其高效、环保和智能化的特点,为当地经济发展注入了新的活力,本文将围绕台湾无人纺织厂为主题,深入探讨其运营模式、技术应用以及案例分析。

台湾无人纺织厂概述

台湾无人纺织厂以其自动化、智能化和高效生产的特点,成为了当地纺织行业的新亮点,这些工厂通常采用先进的机器设备和智能控制系统,实现了生产过程的自动化和智能化管理,这些工厂注重环保和可持续发展,采用环保材料和节能技术,降低了生产成本和环境污染。

运营模式分析

- 自动化生产:台湾无人纺织厂采用先进的自动化生产设备,实现了生产过程的自动化和智能化管理,这些设备可以高效地完成从原料到成品的生产过程,大大提高了生产效率。

- 智能化管理:这些工厂通常配备了智能管理系统,包括生产计划、质量控制、库存管理、物流配送等,通过智能化管理系统,可以实现对生产过程的实时监控和数据分析,提高了生产管理的效率和准确性。

- 绿色生产:为了实现可持续发展,许多台湾无人纺织厂采用了环保材料和技术,这些工厂注重废物的处理和资源的回收利用,降低了生产成本和环境污染,这些工厂还注重员工培训和教育,提高员工的环保意识和生产技能。

技术应用案例分析

- 某纺织厂采用智能控制系统实现自动化生产 该纺织厂采用了先进的机器设备和智能控制系统,实现了从原料到成品的自动化生产,通过智能控制系统,可以实现对生产过程的实时监控和数据分析,提高了生产效率和质量,该工厂还注重环保和可持续发展,采用了环保材料和技术。

- 某无人纺织厂采用物联网技术实现智能化管理 该无人纺织厂采用了物联网技术,实现了对生产过程的实时监控和数据采集,通过物联网技术,可以实现对生产过程的智能化管理和优化,提高了生产管理的效率和准确性,该工厂还注重员工培训和教育,提高了员工的环保意识和生产技能。

随着科技的不断发展,台湾无人纺织厂将会继续发展壮大,这些工厂将会更加注重技术创新和智能化发展,提高生产效率和产品质量,这些工厂还将注重环保和可持续发展,实现绿色生产和循环经济,这些工厂还将加强与上下游企业的合作,形成产业链协同发展。

台湾无人纺织厂以其自动化、智能化和高效生产的特点,成为了当地经济发展的新亮点,这些工厂注重技术创新和智能化发展,注重环保和可持续发展,为当地经济发展注入了新的活力,随着科技的不断发展,这些工厂将会继续发展壮大,成为当地经济发展的重要支柱。

Articles related to the knowledge points of this article:

The Evolution of Tianzhuang East Textile Factory

Fabricating Quality The Role of 定型工艺 in Textile Production

The Fabrication of Success:A Look at the New Qi Zhen Textile Mill