The Duty of a Textile Quality Inspector:A Closer Look at the Job

:The Duty of a Textile Quality Inspector: A Closer Look at the Job,In the realm of textile manufacturing, where precision and quality are paramount, the role of a textile quality inspector is critical. Their mission is to ensure that each product meets the highest standards of excellence, both in terms of design and functionality. The inspector's job involves a rigorous inspection process that involves multiple steps, each aimed at identifying any flaws or defects within the textile material. From visual examination to testing for specific properties, the inspector's expertise ensures that every thread is accounted for, ensuring the end product meets consumer expectations and industry standards. In this article, we delve deeper into the duties and responsibilities of a textile quality inspector, offering insights into how they contribute to the success of the textile industry.

In the world of textiles, quality inspection plays an instrumental role in ensuring that every piece of clothing meets high-standards of durability and aesthetic appeal. At a typical textile plant, a dedicated team of quality inspectors oversees the production process, from raw materials to finished goods, ensuring that every product meets industry standards and customer expectations. In this article, we delve into the duties of a textile quality inspector, exploring various aspects of their work, including their responsibilities, tools of the trade, case studies, and future trends.

What is a Textile Quality Inspector?

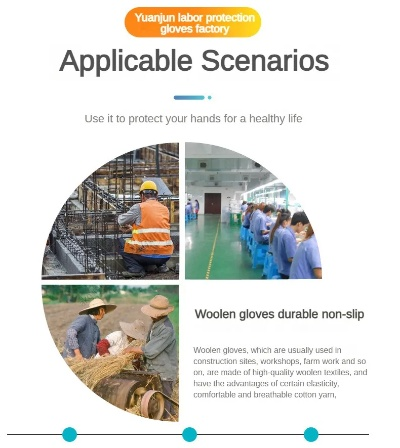

A textile quality inspector is an essential member of a manufacturing team responsible for verifying the quality of fabrics, garments, or any other textile products produced at a textile factory. Their job involves evaluating the physical attributes of the materials used in the production process, as well as checking for defects such as fraying, pilling, color consistency, and fit accuracy. They also assess the overall finish and cleanliness of the final product to ensure it meets the required standards.

Responsibilities of a Textile Quality Inspector

The primary responsibility of a textile quality inspector is to identify and rectify any flaws in the products they evaluate. This includes spotting issues such as thread breaks, loose threads, or missing stitches in garments. Additionally, inspectors are tasked with documenting findings and communicating them to appropriate departments within the company if necessary. They also need to be proficient in using specialized tools such as microscopes, calipers, and stretch meters for accurate assessments.

Tools of the Trade

Quality inspection requires a range of tools, both manual and automated. Common tools include magnifying glasses, calipers, measuring tapes, and rulers to measure dimensions and patterns accurately. For more complex measurements, digital calipers can be used to provide greater precision. Other tools include stretch meters for measuring fabric elasticity and dye transfer tests to check color consistency over multiple batches. Additionally, specialized software is often employed by quality inspectors to track and report on inspection results efficiently.

Case Study: The Impact of Poor Quality Control

Take the example of a textile company producing uniforms for the military. One year, a significant number of uniforms failed quality control checks due to weak stitching and uneven coloration. Investigation revealed that the supplier's raw material had been compromised with inferior fibers, leading to poorer-than-expected performance during the manufacturing process. As a result, the manufacturer had to recall all affected uniforms and compensate customers for damaged items.

This case underscores the importance of thorough quality checks at each stage of the manufacturing process. Failure to do so could have resulted in significant financial losses and reputational damage.

Future Trends in Textile Quality Inspection

As technology continues to evolve, the methods and tools used for quality inspection are likely to follow suit. Automation will play a larger role in reducing human error and increasing inspection speed and accuracy. Artificial intelligence (AI) systems, for instance, could be used to identify potential quality issues before they become visible during visual inspections. Furthermore, the use of sensors and wearable technology might enable real-time monitoring of garment wear and tear.

Another trend is the integration of blockchain technology into textile supply chains to enhance traceability and transparency. By recording every step of the manufacturing process, from raw material procurement to final product inspection, blockchain could help ensure that products meet high standards and are authenticated without the need for external certification.

Conclusion

In summarizing our discussion on the duties of a textile quality inspector, we have explored their roles, responsibilities, tools of the trade, case studies, and future trends. It's clear that quality control is not just about catching flaws; it's about maintaining the integrity of the entire production process and delivering consistent, high-quality products to customers. As the industry continues to embrace technological advancements, quality inspectors must stay ahead of the curve by staying updated on new techniques and tools that can improve efficiency and accuracy.

With this knowledge, textile manufacturers can better protect their brand and customer trust, while consumers can rest assured that what they purchase is of the highest quality.

大家好,今天我们将探讨一个与纺织厂品检文员相关的主题,作为纺织厂品检文员,他们的工作不仅关乎产品质量,还与企业的生产效率和客户满意度息息相关,下面我们将从工作内容、职责、经验和案例等方面进行详细介绍。

日常品检工作

品检文员负责纺织品的质量检查工作,包括原材料检验、半成品检验和成品检验,他们需要按照一定的标准和流程对每一批次的纺织品进行严格的质量检查,确保产品的质量符合相关标准和客户要求。

数据记录与分析

品检文员需要定期整理和分析品检数据,以便更好地了解产品质量情况,为后续的生产和质量控制提供依据,他们还需要利用数据分析工具,对产品的质量数据进行深入挖掘,找出潜在的质量问题,并提出改进措施。

与其他部门沟通协作

在纺织厂中,品检文员需要与采购部门、生产部门、销售部门等多个部门进行沟通协作,他们需要了解各个部门的生产流程和质量控制要求,以确保产品质量符合多个部门的要求,他们还需要与供应商和客户保持密切联系,及时了解客户对产品质量的反馈和建议。

职责

作为纺织厂品检文员,他们的职责主要包括以下几个方面:

-

负责纺织品的质量检查工作,确保产品符合相关标准和客户要求。

-

负责收集和整理品检数据,为后续的生产和质量控制提供依据。

-

与其他部门进行沟通协作,了解各个部门的生产流程和质量控制要求,确保产品质量符合多个部门的要求。

-

协助解决纺织品质量方面的投诉和问题,提高客户满意度。

经验和案例

在纺织厂中,品检文员的经验和案例主要包括以下几个方面:

-

成功案例:某纺织厂在品检工作中发现了一批次不合格的纺织品,经过及时处理和改进,最终提高了产品质量,赢得了客户的信任和好评。

-

经验总结:品检文员需要具备一定的责任心和职业素养,熟悉相关的标准和流程,掌握一定的检测技术和方法,他们还需要具备良好的沟通和协作能力,能够与各个部门进行有效的沟通和协作,在品检工作中,他们还需要具备一定的数据分析能力,能够利用数据分析工具对品检数据进行深入挖掘和分析。

作为纺织厂品检文员,他们的工作不仅关乎产品质量和企业生产效率,还直接影响到客户的满意度和企业的声誉,他们需要具备高度的责任心和职业素养,熟悉相关的标准和流程,掌握一定的检测技术和方法,他们还需要具备良好的沟通和协作能力、数据分析能力和解决问题的能力,才能更好地完成品检工作,提高产品质量和企业效益。

Articles related to the knowledge points of this article:

The Fabric of Our Future:An In-depth Analysis of Textile Mill Roller Workers