The Standards of Thickness Measurement in Textiles

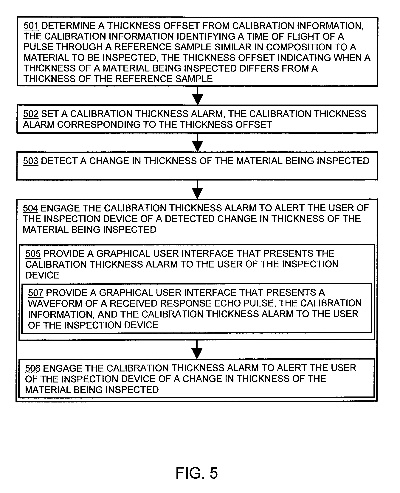

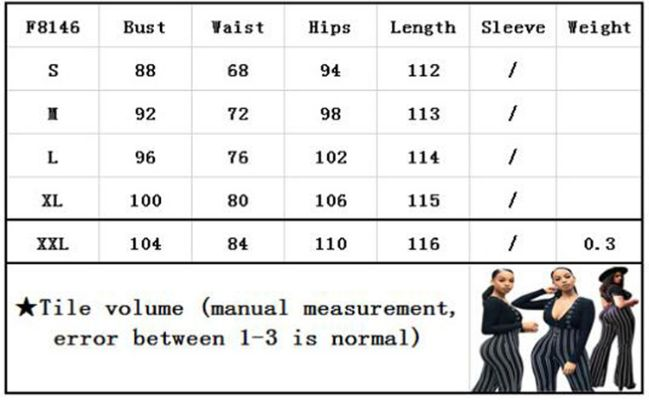

The thickness measurement in textiles is a crucial aspect for quality control and product differentiation. The standards of thickness measurement in textiles are based on the international standard ISO 25107, which defines a method for measuring the thickness of fabrics using a micrometer. This standard requires that the fabric be placed on a flat surface and measured at three different points along its length to ensure accuracy and consistency. Additionally, the standard specifies that the thickness should be measured using a calibrated micrometer with a resolution of 0.01 mm or higher. Overall, the standards of thickness measurement in textiles are important for ensuring that products meet consumer expectations and meet industry requirements.

Introduction: In the world of textiles, understanding the thickness measurement standards is crucial for ensuring quality control and consistency. This guide will provide an overview of the different methods used to measure the thickness of textiles, including their advantages and disadvantages. We'll also discuss common challenges faced by manufacturers and how they are addressed. Finally, we'll explore some real-life examples to illustrate how these standards are implemented in practical settings.

Methodology: The thickness measurement of textiles can be achieved using various techniques, each with its own set of advantages and limitations. Some commonly used methods include:

-

Tape Testing: This technique involves applying adhesive tape to the surface of the fabric and measuring the distance between the adhesive strip and the fabric's edge. It provides a quick and easy way to assess the thickness without damaging the fabric. However, it may not be accurate for thicker materials or those with complex patterns.

-

Tensile Testing: This method involves pulling the fabric through a tensile machine and measuring the force required to do so. It provides a more precise measurement of the material's strength and flexibility. However, it requires specialized equipment and expertise to interpret the results correctly.

-

Magnetic Thickness Gauge: This device uses a magnet to measure the distance between two points on the fabric surface. It is particularly useful for measuring the thickness of non-magnetic materials such as metallized fabrics. However, it may not be suitable for all types of textiles due to the presence of conductive additives.

-

Digital Calipers: These instruments use digital technology to measure the dimensions of fabric samples accurately and quickly. They provide high precision and accuracy, making them ideal for industrial applications where consistent results are critical. However, they can be expensive and require specialized software for data analysis.

Challenges: While these methods offer valuable insights into the thickness of textiles, manufacturers often face several challenges when implementing them. For example, tape testing may not be suitable for certain types of fabrics, while tensile testing may require specialized equipment that is not always available. Additionally, magnetic thickness gauges may not work well for non-magnetic materials, while digital calipers may not be affordable for small businesses.

Real-Life Examples: To illustrate how these standards are implemented in practical settings, let's consider the case of a textile manufacturer who produces clothing for children's wear. The company has developed a standard process for measuring the thickness of their cotton t-shirts using a combination of tape testing and tensile testing.

To begin, the manufacturer selects a representative sample of t-shirts from their inventory and applies adhesive tape to one side of each shirt. Then, they measure the distance between the adhesive strip and the fabric's edge using a tape tester. Next, they perform tensile testing on a smaller sample of the same t-shirts to determine their strength and flexibility.

Based on the results of both tests, the manufacturer can calculate the average thickness of the entire batch of t-shirts. This information is then used to adjust the production process to ensure consistent quality levels across all products.

Conclusion: Understanding the thickness measurement standards in textiles is essential for maintaining product quality and ensuring consistency across different manufacturing processes. By employing a combination of various techniques, manufacturers can achieve accurate and reliable measurements. However, challenges such as cost, equipment availability, and skill requirements must be addressed to fully realize the benefits of these standards. In conclusion, by following these guidelines and staying up-to-date with industry advancements, textile manufacturers can improve their efficiency, reduce waste, and deliver superior products to customers.

随着纺织行业的快速发展,纺织品厚度测量在质量控制和产品开发中扮演着越来越重要的角色,为了确保纺织品的质量和性能,制定一套统一的测量标准至关重要,本篇文章将详细介绍纺织品厚度测量标准,并结合实际案例进行分析。

纺织品厚度测量标准概述

测量目的

纺织品厚度测量旨在确保纺织品在生产过程中的均匀性和一致性,以及最终产品的厚度和质量。

测量方法

根据相关标准和行业规范,纺织品厚度测量通常采用以下方法:

(1)使用卷尺或测厚仪等测量工具; (2)采用光学测量技术或超声波测量技术; (3)结合多种测量方法,确保测量结果的准确性。

测量标准

(1)线密度标准:根据纺织材料的种类和厚度要求,制定相应的线密度标准,棉织物的线密度标准通常在特定范围内。 (2)测量精度:根据测量目的和纺织品类型,确定合适的测量精度,对于高档服装面料,要求较高的测量精度以保证产品质量。 (3)测试方法与流程:制定详细的测试方法与流程,包括样品准备、测量操作、数据处理等步骤。

实际案例分析

某品牌纺织品厚度测量标准应用

某品牌在生产过程中对纺织品厚度进行了严格把控,他们根据纺织材料的种类和厚度要求,制定了相应的厚度测量标准,他们采用了多种测量方法,确保测量结果的准确性,在实际生产过程中,他们采用了卷尺和测厚仪相结合的方法进行测量,他们还结合光学测量技术对样品进行了厚度测试,以确保产品质量符合要求。

纺织品厚度测量案例分析

某服装公司为了确保产品质量和性能,对纺织品厚度进行了严格的测量,他们采用了光学测量技术对不同厚度的纺织品进行了测试,通过使用光学测量技术,他们可以快速准确地获取纺织品的厚度数据,为产品开发提供有力支持,他们还结合了多种测量方法,确保测量结果的准确性,该服装公司生产的纺织品厚度符合国家标准要求,产品质量得到了有效保障。

纺织品厚度测量标准补充说明

- 线密度标准示例:对于棉织物,线密度标准通常在特定范围内,例如XXg/m²至XXg/m³,具体数值可能因不同品牌和型号而有所不同。

- 测量精度要求:对于纺织品厚度测量,要求较高的精度可以确保产品质量和性能的稳定性和可靠性,在实际应用中,应根据纺织品类型和厚度要求来确定合适的测量精度。

- 测试方法与流程补充说明:在实际应用中,应制定详细的测试方法与流程,包括样品准备、测量操作、数据处理等步骤,应确保测试过程符合相关标准和行业规范,以确保测量结果的准确性,还应定期对测量设备进行校准和维护,以保证测量结果的可靠性。

纺织品厚度测量是纺织产品质量控制的重要环节,为了确保纺织品的质量和性能,应制定一套统一的测量标准,并严格按照标准进行测量操作,在实际应用中,应结合实际案例进行分析,以确保测量结果的准确性和可靠性,还应不断优化和完善测量标准和方法,以适应纺织行业发展的需要。

Articles related to the knowledge points of this article:

Exploring the Benefits and Considerations of Whole Home Textiles

The Cost of Yarn in the Textile Industry

The Components of Textile Polyethers:A Comprehensive Analysis

Consumer Complaints about Textile Products in Wuxi A Case Study and Analysis

The Ugandan Textile Market A Global Perspective and Regional Insights