Textile Thermo-Infrared Inspection Standards

: Textile Thermo-Infrared Inspection Standards,Abstract:,The thermo-infrared inspection (TIR) method is a non-destructive testing technology widely used in the textile industry for quality control and defect detection. This paper discusses the standards for TIR inspection, including the selection of appropriate equipment, sample preparation, inspection parameters, data analysis, and interpretation of results. The aim is to provide a comprehensive understanding of the standards for TIR inspection in the textile industry and its application in practical work.

Introduction: The textile industry is a crucial sector that contributes significantly to the global economy. It involves the production of clothing, footwear, and various other materials used in daily life. However, the quality and safety of these products are often overlooked due to the lack of standardized inspection methods. In this article, we will discuss the importance of thermo-infrared (TIR) inspection standards for textiles and how they can be implemented to ensure product quality and consumer safety.

Textile TIR Inspection Standards:

-

Definition and Purpose: Thermo-infrared inspection is a non-destructive testing technique that uses infrared radiation to detect defects in materials by measuring their thermal properties. The purpose of these standards is to provide a framework for inspectors to evaluate the quality and performance of textile products based on consistent criteria.

-

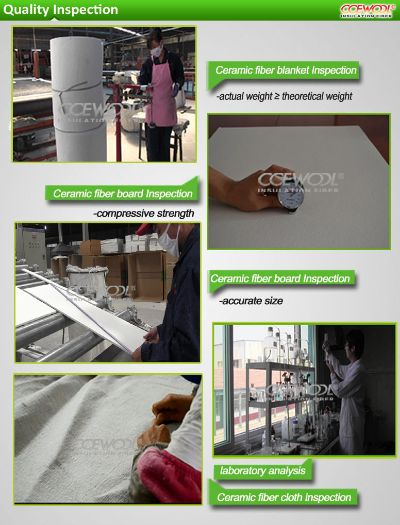

Inspection Process: The TIR inspection process involves several steps, including sample preparation, instrumentation, data collection, and analysis. Here's a table summarizing the key steps:

| Step | Description |

|---|---|

| Sample Preparation | Choose a representative sample from the batch. |

| Instrumentation | Use an appropriate TIR device to measure the sample's thermal properties. |

| Data Collection | Record the temperature measurements taken during the inspection. |

| Analysis | Analyze the data to identify any defects or irregularities in the sample. |

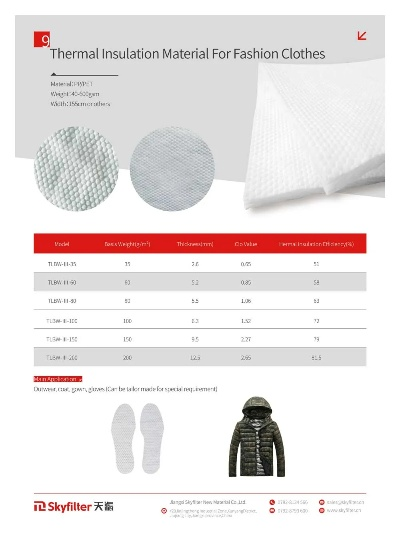

Inspection Criteria: There are several criteria that must be met for a textile product to pass TIR inspection. These include:

| Criteria | Description |

|---|---|

| Appearance | The sample should be free from visible defects such as holes, tears, or stains. |

| Color Match | The color of the sample should match the label or specification. |

| Dimensions | The sample dimensions should be within the specified range. |

| Weight/Volume | The weight or volume of the sample should be accurate and consistent with the label or specification. |

| Material Composition | The material composition should comply with the manufacturer's specifications. |

| Finishing | The finishing of the sample should meet the manufacturer's requirements. |

| Functional Tests | If applicable, functional tests should demonstrate that the product meets its intended use. |

Case Study: Let's take a look at a real-life example of how TIR inspection standards have been implemented in the textile industry. XYZ Corporation produces high-quality cotton fabrics for clothing brands. They use a TIR inspection process to ensure that their products meet strict quality standards.

During the inspection, inspectors found that one batch of fabric had a slight deviation in the yarn count, which could affect the garment's fit and comfort. This defect was immediately flagged and rectified before it could reach the customer. By following TIR inspection standards, XYZ Corporation was able to improve product quality and customer satisfaction while minimizing the risk of recalls or lawsuits.

Conclusion: In conclusion, implementing TIR inspection standards in the textile industry is essential for ensuring product quality and consumer safety. By following these guidelines, manufacturers can avoid costly mistakes and protect their brand reputation. With consistent implementation and adherence to these standards, the textile industry can continue to thrive and meet the needs of consumers worldwide.

随着科技的不断发展,纺织品的质量检测越来越受到人们的关注,远红外检测作为一种先进的检测技术,在纺织品的质量控制中发挥着越来越重要的作用,为了确保纺织品的质量和安全,制定相应的检测标准至关重要,本文将围绕纺织品远红外检测标准展开讨论。

远红外检测标准概述

- 定义与目的

远红外检测标准是对纺织品中远红外辐射性能的检测方法、技术要求和实施细则进行规定,其主要目的是确保纺织品在特定条件下能够发出稳定的远红外辐射,从而满足使用需求。

远红外检测标准主要包括以下几个方面:

- 检测方法:采用特定的仪器设备和方法进行纺织品远红外辐射性能的检测。

- 技术要求:纺织品应具备稳定的远红外辐射性能,辐射强度和稳定性符合相关标准。

- 实施细则:包括检测流程、操作规范、样品处理等方面的具体要求。

案例分析

为了更好地理解远红外检测标准,我们可以结合具体的案例进行分析,以下是一个案例说明:

某品牌纺织品检测标准

该品牌在纺织品生产过程中,采用了先进的远红外检测技术,确保其产品能够满足高质量的使用需求,该标准主要包括以下几个方面:

- 检测方法:采用特定的仪器设备和方法进行纺织品远红外辐射性能的检测。

- 技术要求:纺织品应具备稳定的远红外辐射性能,辐射强度和稳定性达到一定的标准。

- 实施细则:该品牌在样品处理、检测流程等方面都有严格的规定,确保检测结果的准确性和可靠性。

通过该案例可以看出,该品牌在远红外检测方面非常重视,采用了先进的检测技术和严格的标准要求,从而确保了其产品的质量和安全。

纺织品远红外检测标准的具体要求

-

仪器设备要求

- 仪器设备应具备高灵敏度、高分辨率等特性,能够准确、快速地检测纺织品远红外辐射性能。

- 设备应具有稳定性和可靠性,能够保证检测结果的准确性。

-

样品处理要求

- 样品应符合相关标准,具有代表性、均匀性等特性。

- 样品处理过程中应遵循操作规范,确保样品不受损坏。

-

检测流程要求

- 检测流程应科学、规范,包括样品采集、预处理、测试等多个环节。

- 测试过程中应严格按照标准操作流程进行,确保测试结果的准确性和可靠性。

总结与展望

纺织品远红外检测标准是确保纺织品质量的重要手段之一,为了更好地满足市场需求和保障消费者权益,需要不断完善和优化纺织品远红外检测标准,随着科技的不断进步和市场需求的变化,纺织品远红外检测标准将会更加完善和严格,也需要加强相关技术的研发和应用,提高纺织品的质量和安全水平。

Articles related to the knowledge points of this article:

A Comprehensive Guide to Recycling Textile Assets in Changzhou

The Recycling Journey of a Little Friend

Exploring the Wonderland of Disney Home Textiles