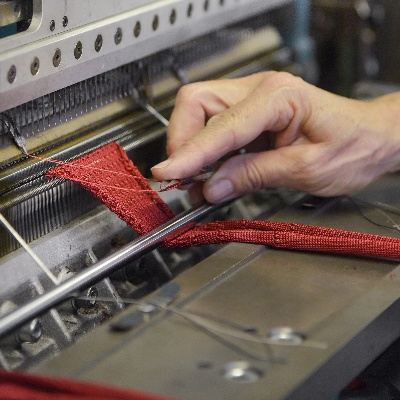

Threading Techniques for Knitting in a Textile Mill:A Comprehensive Guide

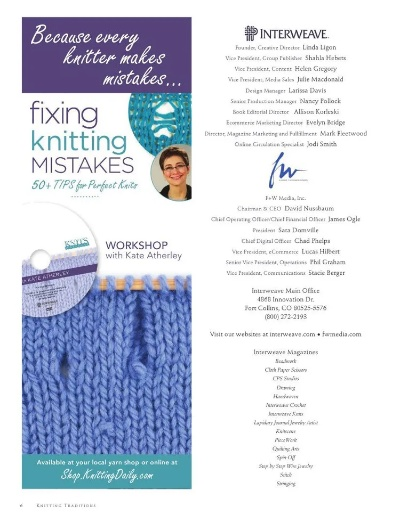

"Threading techniques for knitting in a textile mill offer a comprehensive guide on how to effectively and efficiently complete various knitting tasks. These techniques include proper threading of the needle, selecting the right needle size, managing tension, and ensuring proper stitch formation and shaping. Additionally, it provides detailed instructions on handling different types of yarn, such as wool, silk, and cotton, and how to adjust the tension according to the type of yarn used. The guide also covers common mistakes to avoid when working with yarn, including overtwisting and incorrectly threading the needle. By following these threading techniques, knitters can improve their skills and achieve better results in their projects."

Introduction: Knitting is an art that requires precision and attention to detail, especially in the context of textile mills where machinery is involved. The use of hooked needles (also known as knitting needles) in the production process necessitates proper handling, including how to tie off knots effectively to prevent any potential disruptions during production. In this guide, we will explore various knot-tying techniques suitable for different types of yarns and materials used in textile industries.

Materials Needed:

- Yarn or fabric

- Hooked needles (knitting needles)

- Scissors or knife for cutting loose ends

- Tape measure or ruler for measuring lengths accurately

- Safety glasses or goggles (optional but recommended)

Basic Techniques:

-

Single Knot: A basic knot used to secure one end of yarn or fabric.

- Typical Size: Approximately 2 inches long.

- Example: Insert hook through first loop on left side of fabric or yarn, pull up through second loop, then down through third loop, and finally back up through the first loop. Tighten securely with a double knot.

-

Double Knot: A more secure knot used when you need to hold a piece together while it dries or before cutting into strips.

- Typical Size: Approximately 3 inches long.

- Example: Repeat the Single Knot steps, but instead of pulling up through the first loop, pull down through the second loop and then back up through the first loop. Tighten securely with a double knot.

-

Bow Knot: Used when creating a decorative edge or when making small pieces.

- Typical Size: Small enough to be easily tied off without unraveling.

- Example: Insert hook through first loop on left side of fabric or yarn, draw up through second loop, then draw down through third loop, and then back up through the first loop. Tighten securely with a triple knot.

-

Overhand Knot: Used for securing multiple pieces of yarn at once.

- Typical Size: Approximately 5 inches long, depending on number of pieces.

- Example: Insert hook through the last loop of each piece of yarn or fabric, then draw up through the next pair of loops, and repeat until all pieces are secured. Tighten with a simple knot or double knot.

-

Tie-off Stitches: For sewing two pieces of fabric together.

- Typical Size: Depending on the width of the seam, typically 6 to 8 stitches per inch.

- Example: Use a matching thread and machine needle. Start at the beginning of the fabric and work back and forth across the seam, ensuring tension even throughout.

-

Scissor Knot: A quick and easy way to tie off loose ends.

- Typical Size: Approximately 1 inch long.

- Example: Cut a piece of yarn or fabric flush with the previous knot, leaving about 1/8 inch tail. Tuck the tail inside the knot and tuck the remaining fabric under to hide the cut.

Advanced Techniques: 7. Tie-off for Machine Needles: For using machine knitting needles in a traditional setting.

- Typical Size: Approximately 2 inches long.

- Example: Hold the needle in one hand and insert the other hand's fingers around the tip of the needle, creating a small loop. Pull up through the loop and wrap it around the needle several times, then tighten securely with a double or triple knot.

- Knot for Elastic Bands: For creating elastic bands.

- Typical Size: Approx. 2 to 5 inches long.

- Example: Create a simple knot by inserting hook through one end of the elastic, pulling upward through the next loop, then pulling downward through the last loop and back up through the first loop. Tighten securely with a simple knot.

Case Study: Consider a company that manufactures high-quality garments using cotton yarn for their shirts. They use automated knitting machines that require precise control over yarn handling. Here, proper knot-tying techniques become crucial not only to prevent accidents but also to maintain consistent quality standards throughout the production process.

For example, they implement a standardized procedure whereby every new batch of yarn is thoroughly examined before being used in the factory. This includes checking for any visible defects such as fraying, which could potentially lead to uneven knitting and poor quality garments. Once the inspection is complete, the team follows a set of rules for knot-tying to ensure that each end of yarn remains securely attached to its respective needle, preventing any potential issues during the knitting process.

Moreover, they conduct regular training sessions for their employees to reinforce these procedures and ensure consistency across the production line. These efforts have helped them maintain a high level of product quality, resulting in satisfied customers and positive feedback from retailers and consumers alike.

In conclusion, understanding and mastering the various knot-tying techniques is essential for anyone working in a textile mill or any industry that involves handling yarn or fabric. By implementing these techniques consistently throughout the production process, companies can minimize risks, improve efficiency, and ultimately deliver superior products to their customers.

纺织厂钩针打结概述

在纺织厂中,钩针打结是一项重要的工艺技术,它不仅影响着产品的美观和耐用性,还关系到生产效率和产品质量,本文将详细介绍纺织厂钩针打结的基本原理、操作技巧以及实际应用案例。

钩针打结的基本原理

- 打结原理:钩针打结是通过一系列的钩针动作,将线头或线尾牢固地固定在一起,形成一种特殊的编织结构。

- 打结步骤:选择合适的钩针和线材,然后根据需要编织的图案和结构,选择合适的打结方式,通常包括准备线头、穿入钩针、打结固定等步骤。

操作技巧

- 选择合适的钩针型号和线材:根据需要编织的图案和结构,选择合适的钩针型号和线材,不同材质的线有不同的特性,需要根据实际情况进行选择。

- 掌握打结技巧:在打结过程中,需要注意以下几点:一是要确保线头和线尾的牢固性,避免出现松动或脱落的情况;二是要掌握正确的钩针动作,避免出现错误的打结方式;三是要根据实际情况灵活调整打结方式。

实际应用案例

织毛衣打结 在纺织厂中,毛衣打结是一项常见的工艺技术,下面是一个毛衣编织的案例:

(表格1)

| 步骤 | 描述 | 钩针打结示例 |

|---|---|---|

| 选择线材 | 选择羊毛线作为毛衣的主要材料 | 选择适合的毛衣线 |

| 选择钩针 | 根据毛衣的图案和结构,选择合适的钩针型号 | 选择适合的钩针进行编织 |

| 打结技巧 | 使用钩针将线头和线尾牢固地固定在一起 | 使用适当的钩针动作进行打结,确保牢固性和美观性 |

| 实际操作 | 开始编织毛衣的图案,根据需要适当调整钩针的力度和角度 | 根据图案和结构,灵活运用钩针进行打结,确保毛衣的平整和美观 |

通过这个案例可以看出,纺织厂中钩针打结是一项重要的工艺技术,它不仅影响着产品的美观和耐用性,还关系到生产效率和产品质量,在实际操作中,需要根据实际情况选择合适的钩针型号和线材,掌握正确的钩针动作,灵活运用各种打结方式,才能达到理想的编织效果。

英文案例说明

以下是一个英文案例说明: Knitting Darning in Textile Factory

Case Study: Knotting in a Textile Factory

In a textile factory, knotting is an important craft technique that plays a crucial role in product aesthetics, durability, and production efficiency. This article will provide an overview of the basic principles, operating techniques, and practical application of knotting in textile factories.

-

Knotting Principles Knotting is achieved through a series of hooking actions that secure the ends of the yarn or thread, forming a unique weave structure.

-

Operating Techniques Firstly, selecting the appropriate hooking needle and yarn based on the desired pattern and structure of the knitted product. It involves selecting the appropriate hooking method based on the characteristics of the yarn material.

-

Practical Application Cases (Table 2) | Steps | Description | Knitting Darning Example | | --- | --- | --- | | Selection of Yarn | Selecting wool yarn as the main material for a sweater knitting | Knitting with appropriate sweater yarn according to the pattern and structure desired | | Selection of Hooking Needle | Depending on the pattern and structure of the sweater, selecting an appropriate hooking needle according to the specifications | Using appropriate hooking techniques to achieve secure and aesthetic results | | Knotting Techniques | Employing appropriate hooking techniques to secure the ends of yarn or thread securely and aesthetically | Using appropriate hooking actions to achieve secure and beautiful results based on the actual situation | In this case, the application of knotting in textile factories is common, and it involves various patterns and structures that require specific techniques for successful completion. It is essential to select the appropriate yarn and hooking needle based on the desired pattern and structure, master the correct hooking techniques, and adjust the techniques flexibly according to the actual situation to achieve the desired result.

Articles related to the knowledge points of this article:

The Evolution of Tianzhuang East Textile Factory

The Role of Textile Factory Womens Teachers

Transforming the Industry:The Story of Gaomi Zhengda Textile Factory